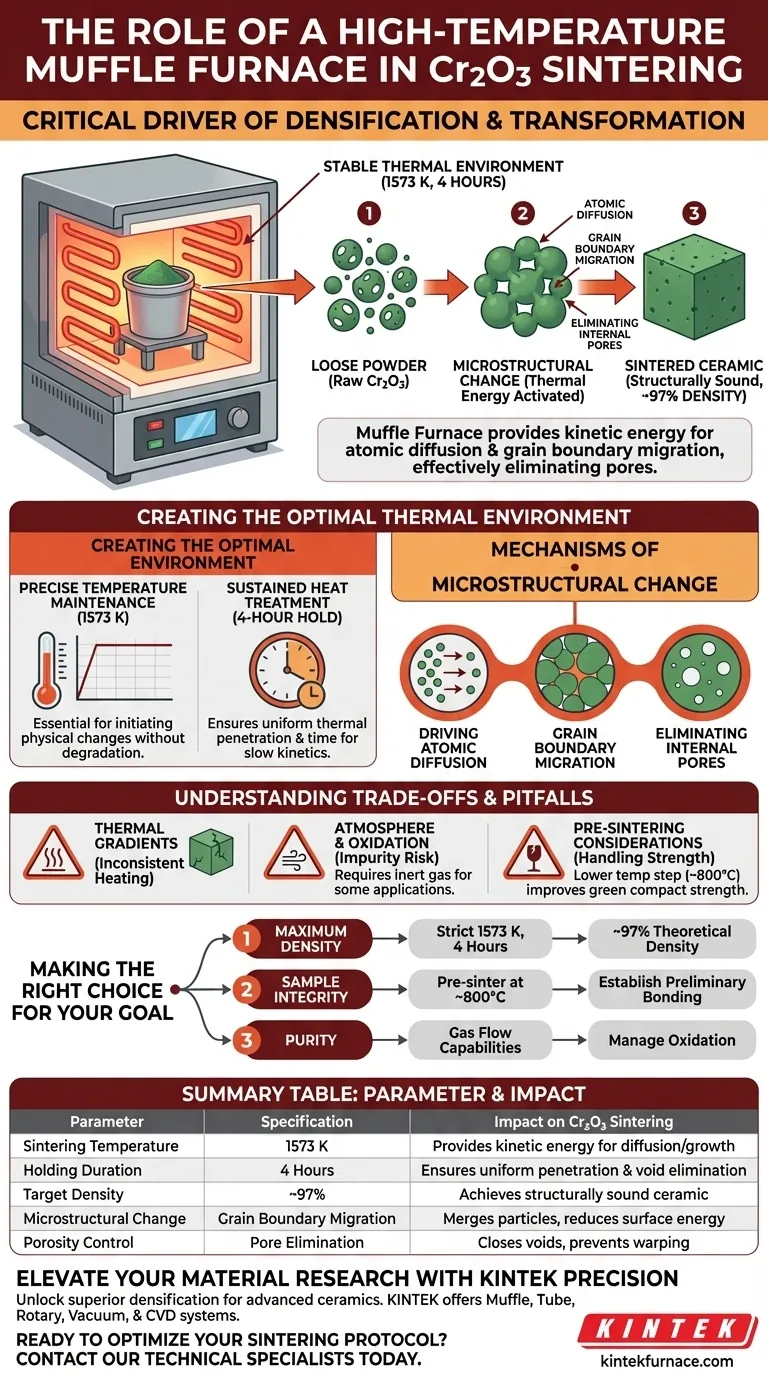

A high-temperature muffle furnace serves as the critical driver of densification for chromium oxide (Cr2O3) particles. By maintaining a stable thermal environment at 1573 K for a sustained four-hour period, the furnace provides the energy required to transform loose powder into a solid, structurally sound material.

The furnace supplies the thermal energy necessary to initiate atomic diffusion and grain boundary migration. This mechanism effectively eliminates internal pores, allowing chromium oxide samples to reach approximately 97% of their theoretical density.

Creating the Optimal Thermal Environment

To achieve high-density ceramics, the processing environment must be rigorously controlled. The muffle furnace isolates the material to ensure uniform heating.

Precise Temperature Maintenance

For chromium oxide, the specific target temperature is 1573 K.

The furnace must reach and maintain this temperature without significant fluctuation. This stability is essential for initiating the physical changes required for sintering without degrading the material.

Sustained Heat Treatment

Reaching the target temperature is not enough; it must be held for a specific duration.

The primary reference dictates a four-hour holding time. This extended duration ensures that the thermal energy penetrates the entire sample volume, allowing time for the slow kinetics of solid-state diffusion to occur.

Mechanisms of Microstructural Change

The heat provided by the muffle furnace triggers specific atomic-level behaviors that alter the physical properties of the material.

Driving Atomic Diffusion

At 1573 K, the atoms within the chromium oxide powder gain significant kinetic energy.

This energy drives atomic diffusion, moving atoms from areas of high concentration to areas of low concentration. This movement is the fundamental "engine" of the sintering process.

Grain Boundary Migration

As atoms diffuse, the individual powder particles begin to bond and merge.

This process involves grain boundary migration, where the interfaces between separate crystals move and coalesce. This reduces the total surface area and surface energy of the system.

Eliminating Internal Pores

The combined effects of diffusion and boundary migration result in the closure of voids between particles.

The furnace's heat drives the elimination of these internal pores. As porosity decreases, the material shrinks and densifies, resulting in a compact solid rather than a loose aggregate.

Understanding the Trade-offs and Pitfalls

While the muffle furnace is the primary tool for densification, improper use or ignoring the broader context can lead to suboptimal results.

The Risk of Thermal Gradients

If the furnace does not have an advanced control system (such as PID control), temperature fluctuations can occur.

Inconsistent heating leads to uneven density, causing warping or cracking. The stability of the 1573 K setpoint is non-negotiable for achieving the 97% density benchmark.

Atmosphere and Oxidation

Standard muffle furnaces operate in air, but this can sometimes be detrimental depending on the exact purity requirements.

While the primary reference focuses on heat, supplementary context notes that some processes require controlled atmospheres (like nitrogen) to prevent unwanted oxidation. Always verify if your specific Cr2O3 application requires an inert environment.

Pre-Sintering Considerations

Directly heating loose powder to 1573 K can sometimes be too aggressive for delicate shapes.

In some workflows, a pre-sintering step at lower temperatures (e.g., 800°C) is used to improve the handling strength of the "green compact" before the final high-temperature firing. Skipping this can lead to structural collapse during the main firing.

Making the Right Choice for Your Goal

To maximize the utility of your muffle furnace for chromium oxide sintering, align your protocol with your specific physical requirements.

- If your primary focus is Maximum Density: Adhere strictly to the 1573 K temperature and 4-hour duration to achieve ~97% theoretical density.

- If your primary focus is Sample Integrity: Consider a pre-sintering stage at ~800°C to establish preliminary bonding before the final high-heat treatment.

- If your primary focus is Purity: Evaluate whether your muffle furnace requires gas flow capabilities to manage oxidation during the heating cycle.

By controlling the thermal variables precisely, you convert raw chromium oxide powder into a mechanically robust, high-performance ceramic.

Summary Table:

| Parameter | Specification | Impact on Cr2O3 Sintering |

|---|---|---|

| Sintering Temperature | 1573 K | Provides kinetic energy for atomic diffusion and grain growth |

| Holding Duration | 4 Hours | Ensures uniform thermal penetration and void elimination |

| Target Density | ~97% | Achieves a structurally sound, high-density ceramic solid |

| Microstructural Change | Grain Boundary Migration | Merges particles and reduces internal surface energy |

| Porosity Control | Pore Elimination | Closes voids between particles to prevent material warping |

Elevate Your Material Research with KINTEK Precision

Unlock superior densification and structural integrity for your advanced ceramics. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your unique sintering parameters.

Whether you are sintering chromium oxide at 1573 K or developing complex CVD processes, our high-temperature lab furnaces provide the thermal stability and atmospheric control required for 97% theoretical density.

Ready to optimize your sintering protocol? Contact our technical specialists today to find the perfect furnace solution for your laboratory needs.

Visual Guide

References

- Thammaporn Thublaor, Somrerk Chandra-ambhorn. Novel Method for Determining Standard Enthalpy and Entropy of Volatilisation of Chromia Exposed to Humidified Oxygen at 298 K Based on Transport Theory of Multicomponent Gas Mixtures. DOI: 10.3390/e27020101

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How are box type resistance furnaces used in the manufacturing of electronic components? Essential for Precise Thermal Processing

- What is the role of precise temperature gradient control in a high-temperature box furnace? Master Mo6S8 Synthesis

- What materials are used in the construction of muffle furnaces? Key Components for High-Temp Performance

- What role does a muffle furnace play in the pyrolysis process for preparing softwood biochar? Expert Insights

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- What role does an industrial muffle furnace play in the calcination of Y211? Master Single-Phase Synthesis

- What is the purpose of using a Muffle furnace for the pretreatment of biochar? Optimize Your Cu/ZnO Catalyst Synthesis

- Why is a muffle furnace used to bake reinforcement particles? Optimize Aluminum Matrix Composite Quality