The high-temperature laboratory furnace serves as the fundamental enabler of plasticity in Barium Titanate (BaTiO3) single crystals. By maintaining a rigorous temperature environment between 1150 °C and 1300 °C, the furnace transforms the crystal from a brittle solid into a state capable of controlled plastic deformation without fracturing.

The furnace does not simply heat the material; it creates a precise thermal window that lowers the crystal's yield stress to activate specific slip systems, while simultaneously protecting the material from catastrophic failure due to thermal shock.

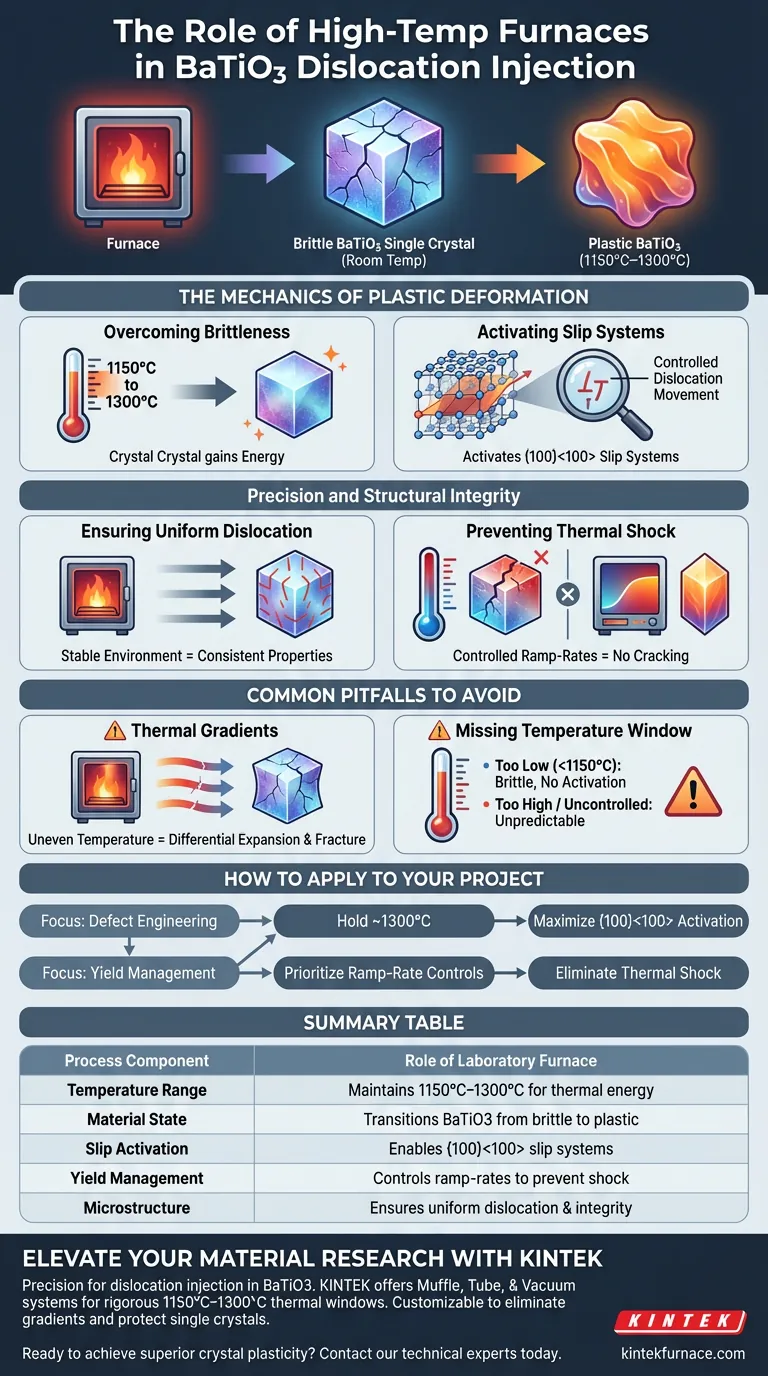

The Mechanics of Plastic Deformation

Overcoming Brittleness

At room temperature, Barium Titanate is inherently brittle and prone to shattering under stress.

The furnace raises the material's temperature to a specific window of 1150 °C to 1300 °C. Within this range, the crystal lattice gains enough energy to allow for plastic flow rather than brittle fracture.

Activating Crystallographic Slip Systems

Heat alone is not the goal; the objective is specific microstructural manipulation.

The thermal energy provided by the furnace is necessary to activate the {100}<100> slip systems. This specific activation allows dislocations (defects) to move and multiply within the crystal structure in a predictable manner.

Precision and Structural Integrity

Ensuring Uniform Dislocation

The furnace provides a stable thermal environment, which is critical for consistency.

Precise temperature control ensures that the dislocations form uniformly along the desired crystal orientations. Without this stability, the dislocation density would be erratic, leading to unpredictable material properties.

Preventing Thermal Shock

Single crystals are highly susceptible to damage from rapid temperature changes.

The furnace acts as a safeguard against thermal shock. By maintaining a controlled environment, it prevents the development of steep thermal gradients that would cause the single crystal to crack or shatter during the process.

Common Pitfalls to Avoid

The Risk of Thermal Gradients

If the furnace fails to maintain a uniform temperature zone, the crystal will experience differential expansion.

This creates internal stress that competes with the desired plastic deformation, often resulting in immediate fracture or latent structural weaknesses.

Missing the Temperature Window

Operating outside the 1150 °C to 1300 °C range renders the process ineffective.

If the temperature is too low, the {100}<100> slip systems will not activate, and the crystal will remain brittle. If control is lost, the specific orientation of the dislocations cannot be guaranteed.

How to Apply This to Your Project

When configuring your thermal processing for Barium Titanate dislocation injection, consider your primary objectives:

- If your primary focus is Defect Engineering: Ensure your furnace can hold a steady temperature closer to 1300 °C to maximize the activation of the {100}<100> slip systems.

- If your primary focus is Yield Management: Prioritize furnace ramp-rate controls to eliminate thermal shock and prevent cracking the single crystal.

Success in dislocation injection relies entirely on balancing the thermal energy required for plasticity with the stability required for crystal survival.

Summary Table:

| Process Component | Role of Laboratory Furnace |

|---|---|

| Temperature Range | Maintains 1150 °C to 1300 °C for thermal energy |

| Material State | Transitions BaTiO3 from brittle to a plastic state |

| Slip Activation | Enables {100}<100> crystallographic slip systems |

| Yield Management | Controls ramp-rates to prevent catastrophic thermal shock |

| Microstructure | Ensures uniform dislocation density and structural integrity |

Elevate Your Material Research with KINTEK

Precision is non-negotiable when performing complex processes like dislocation injection in Barium Titanate. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, and Vacuum systems designed to maintain the rigorous 1150 °C–1300 °C thermal windows required for advanced defect engineering. Our laboratory high-temp furnaces are fully customizable to eliminate thermal gradients and protect your delicate single crystals from fracture.

Ready to achieve superior crystal plasticity? Contact our technical experts today to find the perfect furnace solution for your unique laboratory needs.

Visual Guide

References

- Fangping Zhuo, Jürgen Rödel. Dislocation Density‐Mediated Functionality in Single‐Crystal BaTiO<sub>3</sub>. DOI: 10.1002/advs.202403550

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is working temperature the most crucial factor when choosing a muffle furnace? Ensure Your Process Success with the Right Heat

- What are the main structural components of a box furnace? Essential Guide for Efficient Material Processing

- What is the function of a high-temperature muffle furnace? Master Eggshell Adsorbent Activation

- How does precise temperature control benefit the use of a digital muffle furnace? Unlock Reliable, Repeatable Results

- What is the function of a muffle furnace in preparing MgO nanoparticles? Precise Thermal Decomposition at 630°C

- How does radiant heat transfer from furnace gas to metal work in a box type resistance furnace? Unlock Efficient Heating Insights

- How does a box resistance furnace ensure the stability of microstructural properties during heat treatment of die steels?

- What are the dimensions and capacity of the muffle furnace's chamber? Optimize Your Lab's Heating Efficiency