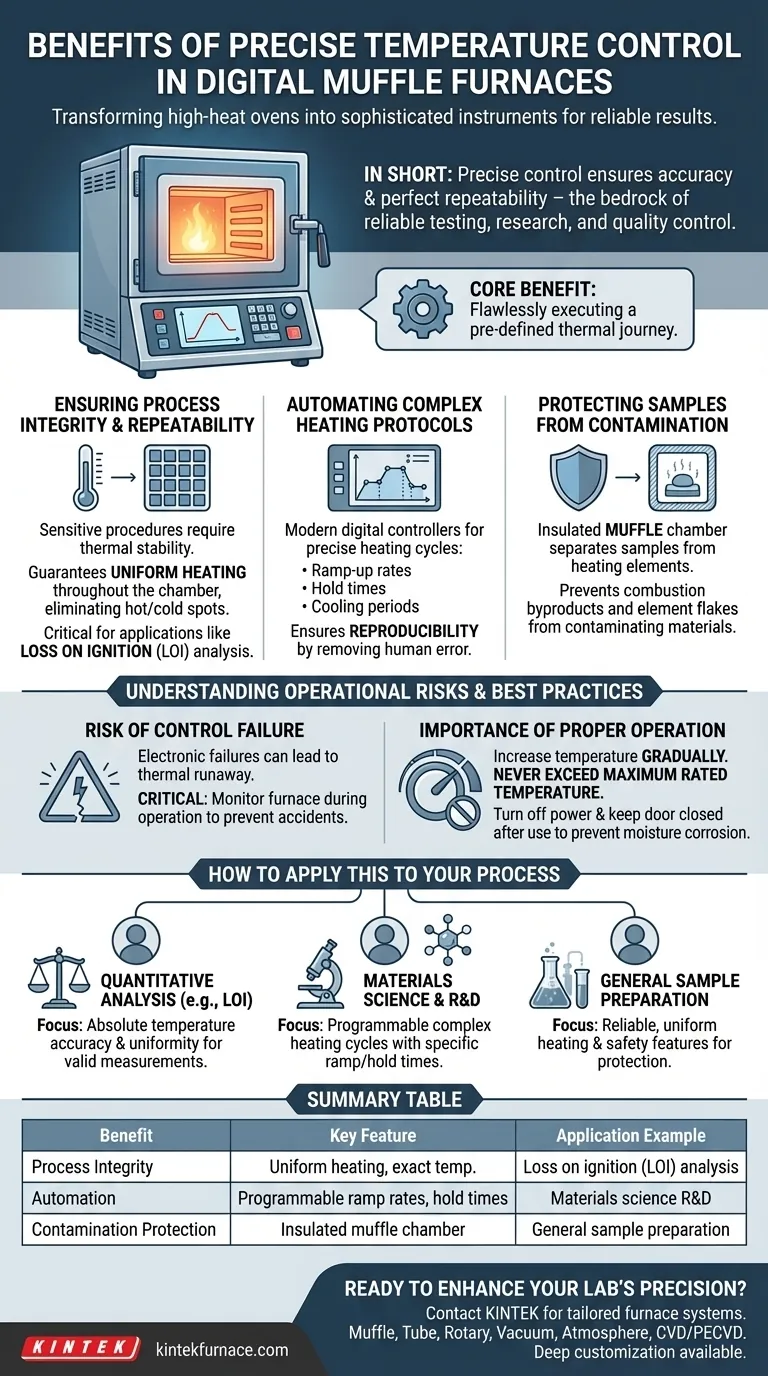

In short, precise temperature control in a digital muffle furnace transforms it from a simple high-heat oven into a sophisticated instrument for scientific and industrial applications. This control ensures that processes are not only accurate but also perfectly repeatable, which is the bedrock of reliable testing, research, and quality control.

The core benefit of digital control isn't just about reaching a specific temperature; it's about flawlessly executing a pre-defined thermal journey. This programmability unlocks the ability to perform complex procedures with unparalleled consistency, which is impossible with simple analog controls.

Why Precision Control is Non-Negotiable

A muffle furnace's primary job is to heat a sample, but the way it heats is what determines its value. Digital control provides a level of precision that is essential for modern applications.

Ensuring Process Integrity and Repeatability

Many analytical procedures are extremely sensitive to thermal variations. A slight deviation in temperature can alter a material's properties or invalidate a test result.

Precise control guarantees uniform heating throughout the chamber, eliminating hot or cold spots that could compromise the sample.

This is critical for applications like loss on ignition (LOI) analysis, where the mass of a sample is measured after heating. The accuracy of the result depends entirely on the temperature being exact and consistent.

Automating Complex Heating Protocols

Modern digital furnaces feature programmable controllers that go far beyond a simple temperature setting.

Users can define precise heating cycles, including:

- Ramp-up rates: How quickly the temperature rises.

- Hold times: How long the furnace maintains a specific temperature.

- Cooling periods: Controlled or natural cooling phases.

This automation ensures every sample undergoes the exact same thermal profile, a concept known as reproducibility. This removes human error and guarantees that results from different batches can be compared reliably.

Protecting Samples from Contamination

The "muffle" itself is an insulated chamber that separates the sample from the heating elements.

This design prevents combustion byproducts or flakes from the elements from contaminating the material being tested. When combined with precise temperature control, it ensures the sample is only affected by the intended thermal process.

Understanding the Trade-offs and Operational Risks

While digital control offers immense benefits, it does not eliminate the need for proper operational procedures and awareness of potential failures.

The Risk of Control Failure

Even with sophisticated automation, electronic components can fail. A malfunctioning controller could lead to a "thermal runaway" event where the temperature rises uncontrollably.

It is critical to monitor the furnace during operation to prevent accidents. This ensures you can intervene if the automatic controls fail, protecting both your sample and the equipment.

The Importance of Proper Operation

To ensure the longevity of the furnace, especially the heating elements, the temperature should always be increased gradually. Abruptly setting the furnace to its maximum temperature can cause damage.

Likewise, you must never exceed the maximum rated temperature of the furnace, as this can permanently burn out the heating elements.

After use, always turn off the power and keep the furnace door closed. This protects the sensitive internal chamber from ambient moisture, which can cause corrosion and degradation over time.

How to Apply This to Your Process

Your specific application dictates which aspect of temperature control is most critical for your work.

- If your primary focus is quantitative analysis (like LOI): Your priority is absolute temperature accuracy and uniformity to ensure your measurements are valid and repeatable.

- If your primary focus is materials science or R&D: The ability to program complex heating cycles with specific ramp and hold times is your most valuable feature.

- If your primary focus is general sample preparation: The key benefits are reliable, uniform heating and the safety features that protect your samples and the furnace itself.

Ultimately, precise temperature control is what enables a muffle furnace to deliver results you can trust.

Summary Table:

| Benefit | Key Feature | Application Example |

|---|---|---|

| Process Integrity | Uniform heating, exact temperature | Loss on ignition (LOI) analysis |

| Automation | Programmable ramp rates, hold times | Materials science R&D |

| Contamination Protection | Insulated muffle chamber | General sample preparation |

Ready to enhance your lab's precision and efficiency with advanced high-temperature solutions? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide diverse laboratories with tailored furnace systems. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how we can help you achieve reliable, repeatable results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a muffle furnace play in the conversion of S-1@TiO2? Achieve Precision Calcination of Nanospheres

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- What is the primary use of a muffle furnace in the assembly of side-heated resistive gas sensors? Expert Annealing Guide

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration