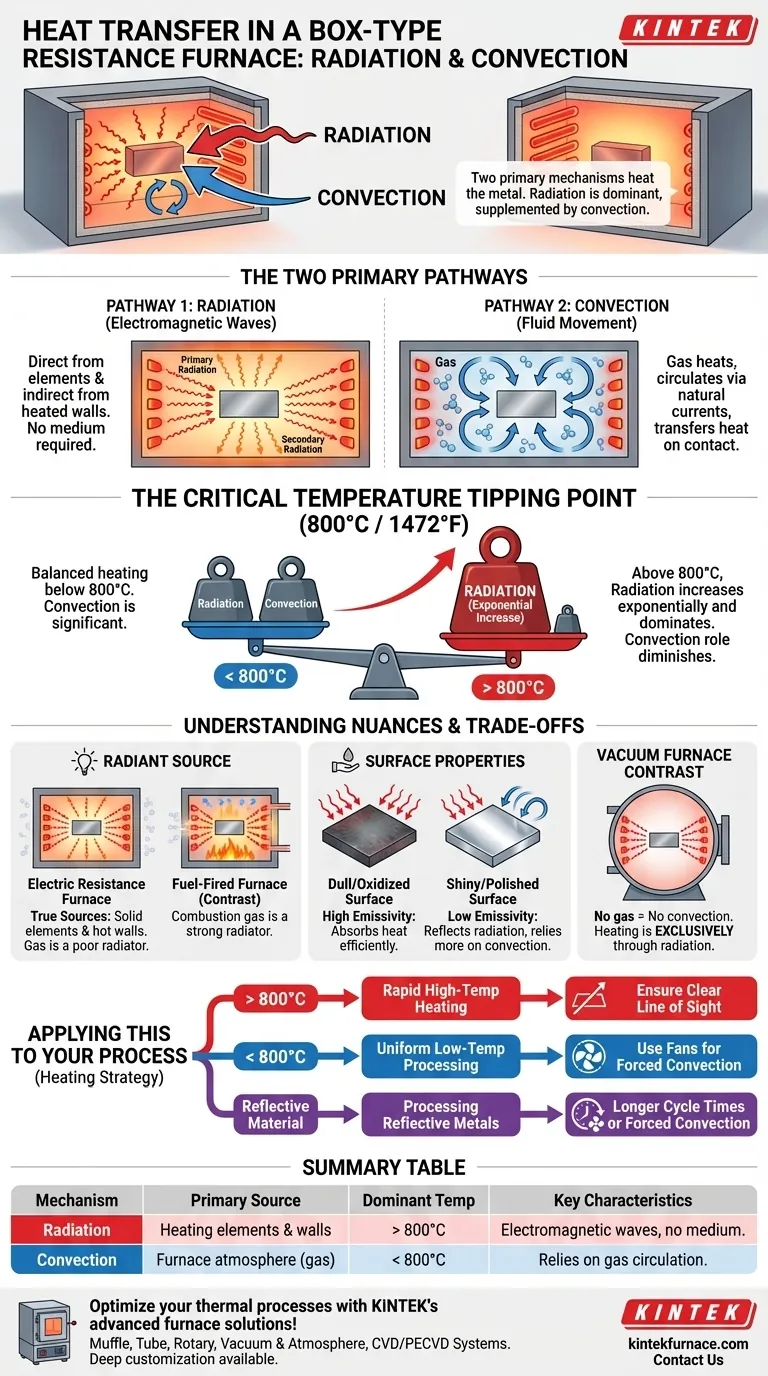

In a box-type resistance furnace, heat transfer from the furnace to the metal workpiece is a dynamic process involving two primary mechanisms. The dominant force is radiation, which travels as electromagnetic waves directly from the hot electric heating elements and indirectly from the heated furnace walls. This is supplemented by convection, where the furnace atmosphere (air or inert gas) circulates and transfers heat upon contact with the metal.

The central principle to understand is that the efficiency of these two mechanisms changes dramatically with temperature. At lower temperatures, convection and radiation are both significant, but as the furnace exceeds approximately 800°C (1472°F), radiant heat transfer increases exponentially and becomes the overwhelmingly dominant method of heating.

The Two Primary Pathways of Heat Transfer

To control a furnace effectively, you must understand how heat actually reaches your workpiece. It isn't a single action, but a combination of direct and indirect transfers happening simultaneously.

Pathway 1: Direct and Indirect Radiation

Radiation is the transfer of energy via electromagnetic waves (specifically infrared) and requires no physical medium. This is the most powerful heating mechanism in a high-temperature furnace.

The process involves two key steps:

- Primary Radiation: The electric resistance heating elements are the heat source. As they reach high temperatures, they glow and radiate immense amounts of energy in all directions. A portion of this energy travels in a direct line of sight to the metal workpiece.

- Secondary Radiation: The majority of the energy radiated by the elements strikes the internal refractory walls and roof of the furnace. These surfaces absorb the energy, heat up, and become secondary radiators themselves, re-radiating that heat towards the workpiece. This creates a "circulating radiation" effect that helps ensure a more uniform temperature environment.

Pathway 2: The Role of Convection

Convection relies on the movement of a fluid—in this case, the gas inside the furnace—to transfer heat.

The process works as follows:

- Gas Heating: The atmosphere inside the furnace (e.g., air or nitrogen) is heated when it comes into contact with the hot heating elements and the furnace's internal walls.

- Heat Transfer: This heated gas circulates via natural convection currents. As the warmer, less dense gas rises and cooler, denser gas sinks, it flows around the workpiece, transferring its thermal energy upon contact.

The Critical Temperature Tipping Point

The relationship between radiation and convection is not static; it is highly dependent on the furnace's operating temperature.

The Shift Above 800°C

At furnace temperatures below roughly 800°C, the heating effects of radiation and convection are relatively balanced. Convection plays a substantial role in bringing the workpiece up to temperature.

However, the power of radiant heat transfer is proportional to the fourth power of the absolute temperature (the Stefan-Boltzmann law). This means that as temperature climbs, the amount of energy transferred by radiation increases exponentially. Above 800°C, radiant heat transfer rapidly overtakes convection to become almost the sole method of heating.

Understanding the Nuances and Trade-offs

A common point of confusion is the source of radiation and the role of the furnace gas. Clarifying this is key to mastering the process.

The Myth of "Radiant Gas" in a Resistance Furnace

Some descriptions incorrectly imply the furnace gas itself is a primary radiator. This is more characteristic of fuel-fired furnaces where combustion byproducts like CO₂ and water vapor are strong radiators.

In an electric resistance furnace, the atmosphere (air, nitrogen, etc.) is a very poor radiator. Its main role is to transfer heat via convection. The true sources of radiation are the solid heating elements and the hot refractory walls.

The Impact of Surface Properties

The effectiveness of radiant heat transfer depends on the surface of the workpiece.

- Dull, dark, or oxidized surfaces have high emissivity, meaning they absorb radiant energy very efficiently.

- Shiny, polished surfaces (like clean aluminum) have low emissivity. They reflect a significant portion of radiant energy and will heat much more slowly, relying more heavily on convection, especially at lower temperatures.

The Vacuum Furnace Contrast

Understanding a vacuum furnace highlights the role of convection. In a vacuum, there are virtually no gas molecules. Therefore, heat transfer by convection is impossible.

Heating in a vacuum furnace occurs exclusively through radiation. This makes it essential for processing highly sensitive materials but also demonstrates why an atmosphere is critical for efficient, uniform heating at lower temperatures where convection is needed.

Applying This to Your Process

Your heating strategy should adapt based on your specific temperature target and material.

- If your primary focus is rapid high-temperature heating (>800°C): Your process is dominated by radiation. Ensure a clear line of sight between elements/hot walls and the workpiece for maximum efficiency.

- If your primary focus is uniform low-temperature processing (<800°C): You must account for both convection and radiation. Consider using fans to force convection and ensure even temperature distribution, preventing hot and cold spots.

- If you are processing reflective materials: Acknowledge that they will resist radiant heating. You may need longer cycle times or to rely more on forced convection to achieve the target temperature efficiently.

By understanding the interplay of radiation and convection, you can move from simply operating the furnace to truly engineering your thermal process.

Summary Table:

| Mechanism | Primary Source | Dominant Temperature Range | Key Characteristics |

|---|---|---|---|

| Radiation | Heating elements and furnace walls | Above 800°C | Transfers heat via electromagnetic waves, no medium needed |

| Convection | Furnace atmosphere (e.g., air, gas) | Below 800°C | Relies on gas circulation for heat transfer |

Optimize your thermal processes with KINTEK's advanced furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnaces like Muffle, Tube, Rotary, Vacuum & Atmosphere, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, enhancing efficiency and performance. Contact us today to discuss how we can support your specific requirements!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production

- How do you prevent maintenance on a muffle furnace? Extend Lifespan with Proactive Care

- What is the role of a muffle furnace in the study of biochar regeneration and reuse? Unlock Sustainable Water Treatment

- What is the primary function of a muffle furnace for BaTiO3? Master High-Temp Calcination for Ceramic Synthesis

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control