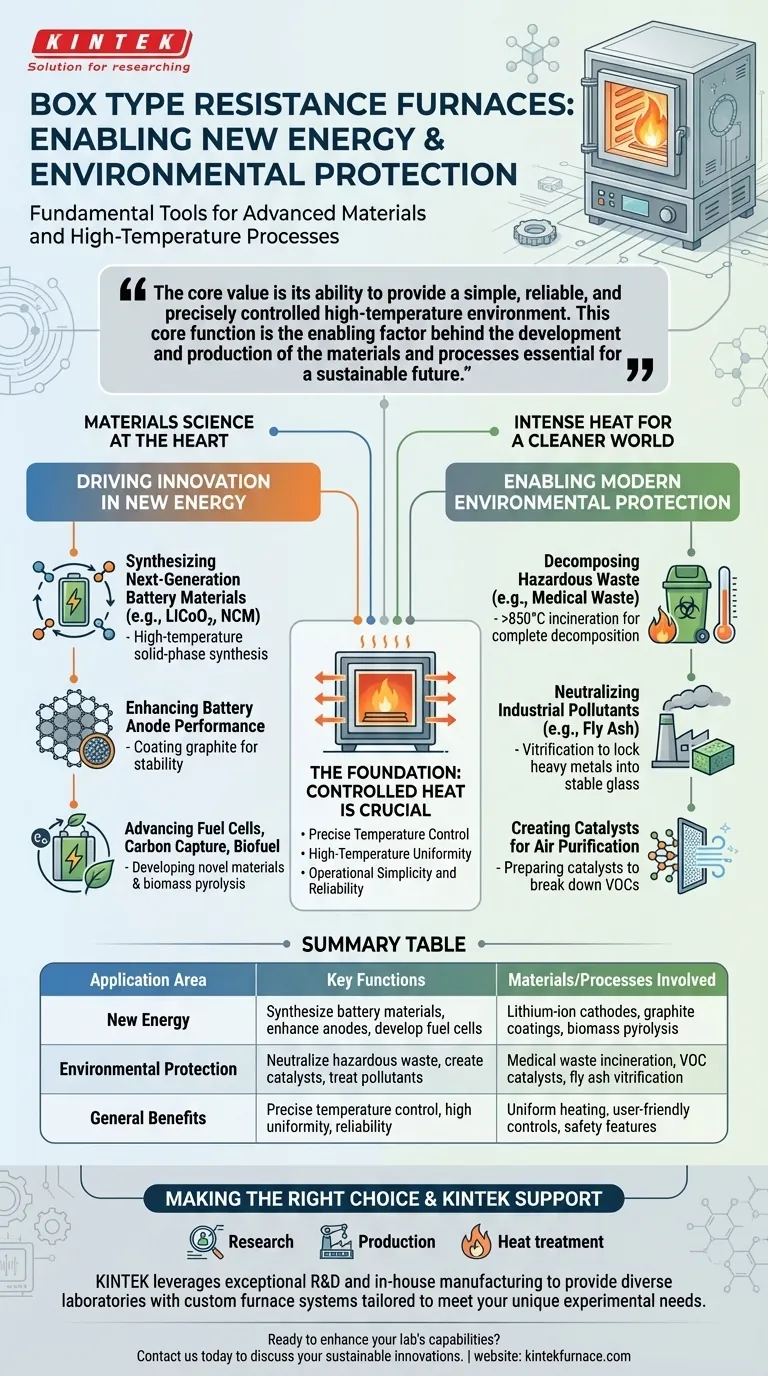

In short, box type resistance furnaces are fundamental tools for creating the advanced materials and executing the high-temperature processes that underpin new energy and environmental protection technologies. They are used to synthesize critical components for lithium-ion batteries, create catalysts that clean our air, and safely neutralize hazardous waste through thermal decomposition.

The core value of a box type resistance furnace is its ability to provide a simple, reliable, and precisely controlled high-temperature environment. This core function is the enabling factor behind the development and production of the materials and processes essential for a sustainable future.

The Foundation: Why Controlled Heat is Crucial

A box type resistance furnace operates on a straightforward principle: electric current passes through resistance wires, generating heat that is radiated uniformly within an insulated chamber. This simplicity is its greatest strength, offering a reliable and controllable environment for complex thermal processes.

Precise Temperature Control

Many advanced materials only form their desired structures within a very narrow temperature window. Likewise, the complete and safe destruction of certain pollutants requires maintaining a specific minimum temperature. These furnaces provide the precise thermal management necessary for both.

High-Temperature Uniformity

The "box" design, combined with optimized placement of heating elements, ensures that the entire workload inside the furnace experiences the same temperature. This uniformity is critical for consistent quality in material synthesis and predictable results in waste treatment.

Operational Simplicity and Reliability

Modern furnaces are designed with user-friendly controls and robust safety features like over-temperature alarms. Their simple structure translates to high reliability and ease of use, making them practical workhorses in both research labs and industrial settings.

Driving Innovation in New Energy

The push for cleaner energy sources relies heavily on materials science, and box furnaces are at the heart of this research and production.

Synthesizing Next-Generation Battery Materials

The performance of lithium-ion batteries is dictated by the chemical structure of their cathode materials, such as Lithium Cobalt Oxide (LiCoO₂) and NCM ternary materials. These are created through high-temperature solid-phase synthesis, a process where the furnace's precise heat facilitates the chemical reactions that form the required crystalline structure.

Enhancing Battery Anode Performance

To improve battery lifespan and charging speed, materials like graphite are often modified. A box furnace can be used to coat graphite particles with a layer of amorphous carbon, a process that enhances their stability and performance as an anode.

Advancing Fuel Cells and Carbon Capture

These furnaces are also vital in the lab for developing future technologies. They are used to prepare and test novel materials for fuel cells, experiment with materials for carbon capture and storage, and convert biomass into biofuel through pyrolysis.

Enabling Modern Environmental Protection

Box furnaces provide the intense heat required to break down or permanently contain some of our most difficult environmental contaminants.

Decomposing Hazardous Waste

High-temperature incineration is a proven method for the harmless disposal of materials like medical waste. A box furnace can maintain temperatures above 850°C, ensuring the complete thermal decomposition of pathogens and hazardous organic compounds.

Neutralizing Industrial Pollutants

Fly ash, a byproduct of combustion, often contains heavy metals that pose an environmental risk. By melting the ash in a furnace at high temperatures, these heavy metals are locked into a stable, non-leachable glassy matrix, rendering them inert.

Creating Catalysts for Air Purification

Many air pollution control systems rely on catalysts to break down harmful compounds like Volatile Organic Compounds (VOCs). Box furnaces are used to prepare these catalysts, such as by binding platinum to an aluminum oxide (Al₂O₃) support, creating the tool that other systems then use to clean waste gas streams.

Understanding the Trade-offs

While incredibly versatile, it is important to understand the operational context and limitations of these furnaces.

Energy Consumption

Reaching and maintaining high temperatures is an energy-intensive process. While modern designs have greatly improved efficiency with high-grade insulation and optimized controls, energy cost remains a primary operational consideration.

Batch Processing Limitations

By its nature, a box furnace is a batch-processing tool. Materials are loaded, heated, and then removed. This is ideal for labs and specialized production but can be a bottleneck in high-volume, continuous manufacturing where tunnel or conveyor furnaces may be more suitable.

Atmospheric Constraints

A standard box furnace operates in an air atmosphere. While sufficient for many applications, processes requiring a specific inert (e.g., nitrogen, argon) or vacuum environment to prevent oxidation will require a more specialized furnace design, such as a tube or vacuum furnace.

Making the Right Choice for Your Application

The versatility of the box type resistance furnace means its value is defined by your specific goal.

- If your primary focus is research and material development: Its precision, flexibility, and reliability make it the ideal platform for testing new formulas for batteries, catalysts, and other advanced materials.

- If your primary focus is specialized production: It is an essential tool for executing critical manufacturing steps, such as synthesizing high-value cathode materials or performing specific waste vitrification protocols.

- If your primary focus is versatile, multi-purpose heat treatment: It serves as a dependable workhorse for a wide range of tasks, from laboratory sample preparation to small-batch component annealing.

Ultimately, the box type resistance furnace is a quiet but critical enabler, providing the controlled thermal energy needed to build the technologies of a cleaner world.

Summary Table:

| Application Area | Key Functions | Materials/Processes Involved |

|---|---|---|

| New Energy | Synthesize battery materials, enhance anodes, develop fuel cells | Lithium-ion cathodes (e.g., LiCoO₂), graphite coatings, biomass pyrolysis |

| Environmental Protection | Neutralize hazardous waste, create catalysts, treat industrial pollutants | Medical waste incineration, VOC catalysts, fly ash vitrification |

| General Benefits | Precise temperature control, high uniformity, operational reliability | Uniform heating, user-friendly controls, safety features |

Ready to enhance your lab's capabilities with advanced high-temperature solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide diverse laboratories with custom furnace systems. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, tailored to meet your unique experimental needs in new energy and environmental protection. Contact us today to discuss how we can support your sustainable innovations!

Visual Guide

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- What is a tubular furnace? Precision Heating for Lab and Industrial Applications

- In which industries is the tube furnace commonly used? Essential for Materials Science, Energy, and More

- Why is uniform heating important in tubular furnaces? Ensure Process Reliability and Predictable Results

- What types of production processes benefit from the thermal uniformity of tube furnaces? Enhance Precision in Material Processing