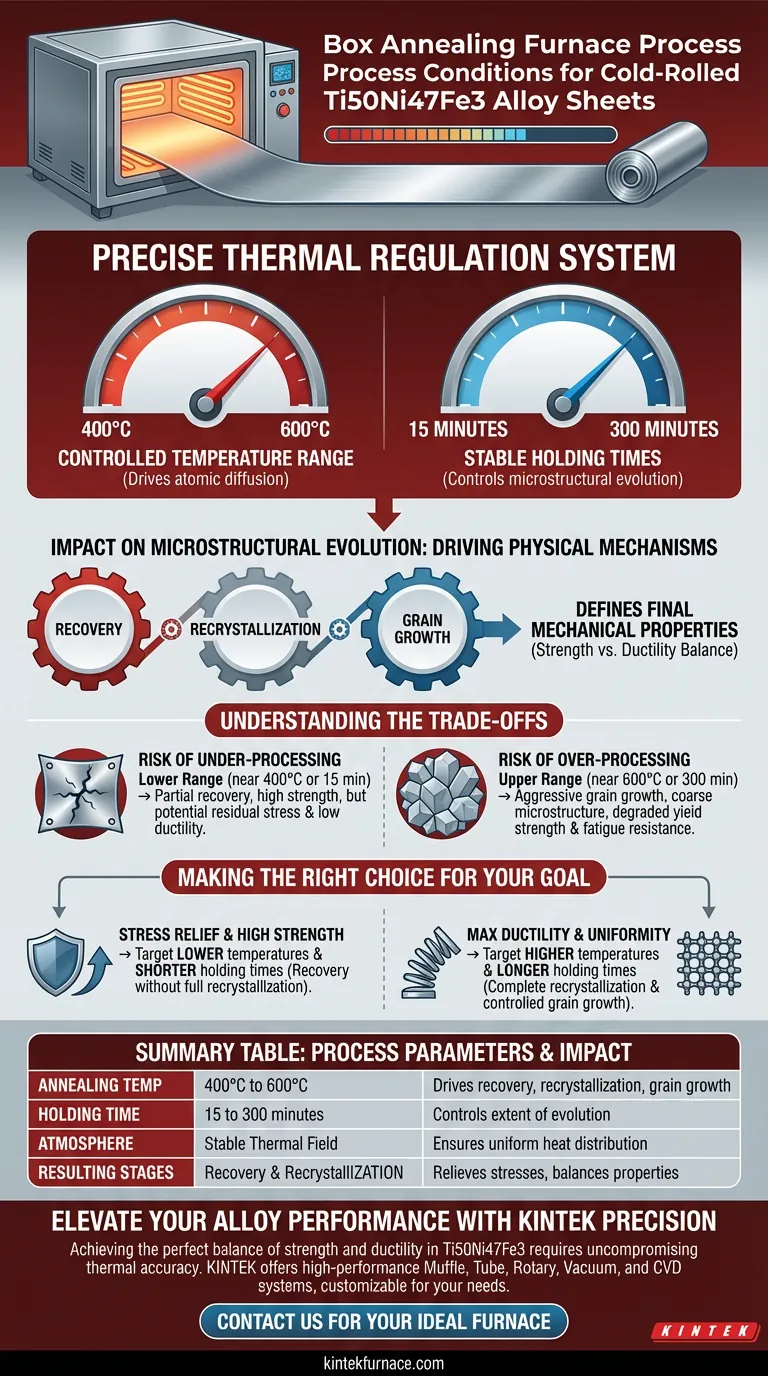

The box annealing furnace functions as a precise thermal regulation system during the heat treatment of cold-rolled Ti50Ni47Fe3 alloy sheets. Specifically, it provides a strictly controlled temperature range between 400°C and 600°C, combined with stable holding times extending from 15 minutes up to 300 minutes.

Core Takeaway The furnace's primary role is to establish an accurate heat field that serves as the physical foundation for microstructural change. By manipulating temperature and time within these specific windows, the process drives recovery, recrystallization, and grain growth, which are the direct determinants of the alloy's final mechanical properties.

The Critical Thermal Environment

To ensure the successful processing of Ti50Ni47Fe3, the furnace must maintain rigid environmental parameters.

Precise Temperature Control

The furnace operates within a specific thermal window of 400°C to 600°C.

This range is not arbitrary; it is calibrated to provide the necessary thermal energy to activate atomic diffusion without inducing uncontrolled grain coarsening or melting.

Stable Holding Times

The equipment facilitates holding periods ranging from 15 minutes to 300 minutes.

This flexibility allows operators to control the extent of the thermal exposure, determining how far the microstructural evolution is allowed to progress.

Impact on Microstructural Evolution

The thermal conditions provided by the furnace are the drivers for the physical transformation of the alloy.

Driving Physical Mechanisms

The accurate heat field induces three distinct stages of evolution: recovery, recrystallization, and grain growth.

These mechanisms relieve the internal stresses introduced during cold rolling and reorganize the crystalline structure of the material.

Determining Final Properties

The specific combination of temperature and time directly dictates the final microstructure evolution.

Consequently, the furnace conditions define the mechanical performance of the alloy, balancing characteristics such as strength and ductility based on the extent of recrystallization achieved.

Understanding the Trade-offs

While the furnace offers a broad operating window, navigating the extremes of these parameters involves inherent trade-offs.

The Risk of Under-Processing

Operating at the lower end of the spectrum (near 400°C or 15 minutes) may only induce partial recovery.

While this retains high strength, it may fail to fully eliminate residual stresses or achieve sufficient ductility for subsequent forming operations.

The Risk of Over-Processing

Conversely, pushing the process toward the upper limits (near 600°C or 300 minutes) promotes aggressive grain growth.

Excessive grain growth can lead to a coarse microstructure, which often degrades the yield strength and fatigue resistance of the final sheet.

Making the Right Choice for Your Goal

Selecting the correct set points within the furnace's capabilities depends entirely on the desired mechanical outcome for the Ti50Ni47Fe3 alloy.

- If your primary focus is stress relief with high strength: Target the lower temperature range and shorter holding times to induce recovery without full recrystallization.

- If your primary focus is maximum ductility and uniformity: Utilize higher temperatures and longer holding times to ensure complete recrystallization and controlled grain growth.

The precision of your thermal control is the single most important factor in transforming cold-rolled potential into reliable mechanical performance.

Summary Table:

| Parameter | Range/Condition | Impact on Ti50Ni47Fe3 Alloy |

|---|---|---|

| Annealing Temp | 400°C to 600°C | Drives recovery, recrystallization, and grain growth |

| Holding Time | 15 to 300 minutes | Controls extent of microstructural evolution |

| Atmosphere | Stable Thermal Field | Ensures uniform heat distribution for mechanical consistency |

| Resulting Stages | Recovery & Recrystallization | Relieves internal stresses and balances strength vs. ductility |

Elevate Your Alloy Performance with KINTEK Precision

Achieving the perfect balance of strength and ductility in Ti50Ni47Fe3 alloys requires uncompromising thermal accuracy. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique material science needs.

Whether you require precise recovery cycles or complete recrystallization, our lab high-temp furnaces provide the stable heat fields necessary for superior results. Contact us today to find the ideal furnace for your application!

Visual Guide

References

- Shuwei Liu, Songxiao Hui. Effect of Annealing on the Microstructure, Texture, and Properties of Cold-Rolled Ti50Ni47Fe3 Shape Memory Alloy Sheets. DOI: 10.3390/cryst14040360

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

People Also Ask

- How does an industrial high-temperature furnace simulate the blast furnace reduction environment? Achieve 30% Reduction

- What are some applications of inert ovens in metallurgy? Enhance Metal Properties Safely

- What is the maximum temperature a low vacuum atmosphere furnace can achieve? Unlock Precision Heat Treatment Solutions

- What is the function of an industrial resistance furnace in melting Al-Fe-Ni-Sc-Zr alloys? Achieve Alloy Homogeneity

- What high-temperature processes commonly use argon in furnaces? Essential Guide for Reactive Metals

- What is an example of gas used for annealing titanium alloys, and why? Discover the Essential Role of Argon for Superior Results

- What is the primary function of an air oxidation furnace in carbon chain synthesis? Optimize SWCNT Pretreatment

- How is the atmosphere controlled in an atmosphere protection muffle furnace? Master Precise Gas Control for Superior Results