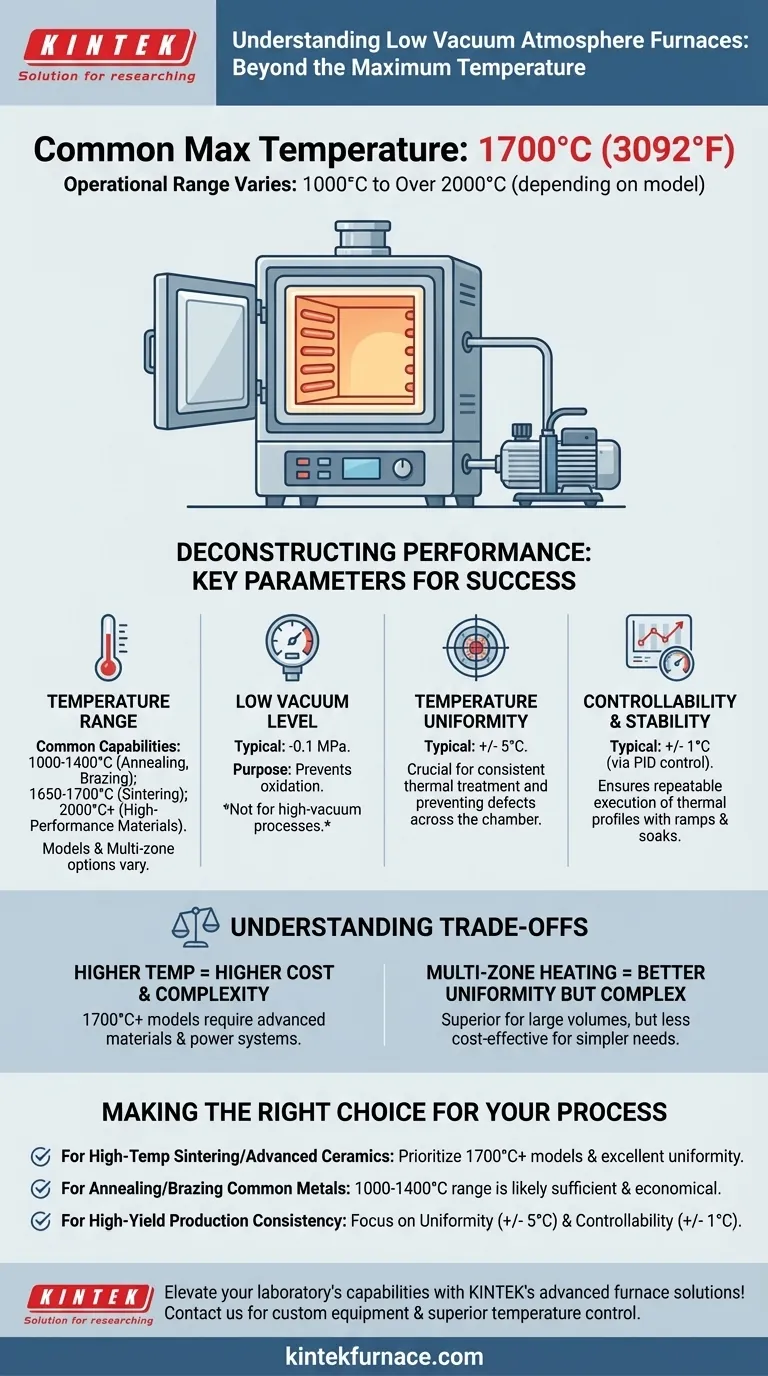

In short, the maximum temperature for a common low vacuum atmosphere furnace is 1700°C (3092°F). However, this figure is not universal; the operational temperature range depends heavily on the specific model and its intended application, with different series offering maximums from 1000°C (1832°F) to over 2000°C (3632°F).

Evaluating a low vacuum furnace requires looking beyond its maximum temperature. The true measure of its capability lies in the combination of heat, vacuum level, temperature uniformity, and control stability, as these factors collectively determine the success and repeatability of your heat treatment process.

Deconstructing Furnace Performance

Choosing the right furnace means understanding its core operational parameters. The maximum temperature is a headline specification, but the details of how that heat is controlled and distributed are what ensure high-quality, repeatable results.

The Spectrum of Maximum Temperatures

There is no single maximum temperature for all low vacuum furnaces. Manufacturers offer a range of models tailored to different processes.

Common temperature capabilities you will encounter include:

- 1000°C to 1400°C: Often sufficient for processes like annealing and brazing.

- 1650°C to 1700°C: A common upper limit for many general-purpose and advanced furnaces used for sintering and other demanding applications.

- 2000°C and higher: Available in specialized series designed for high-performance materials.

These variations are often organized into different "series" or models, with some offering multi-zone heating configurations that might have different maximums (e.g., 1200°C, 1400°C, or 1700°C options).

Defining "Low Vacuum"

The term "low vacuum" in this context refers to the furnace's ability to reduce atmospheric pressure, primarily to prevent oxidation.

A typical operational vacuum level for these furnaces is -0.1 MPa. This environment is suitable for most heat treatment processes where removing the majority of oxygen is the primary goal.

Why Uniformity is as Important as Heat

Temperature uniformity is a measure of how consistent the temperature is across the entire heating chamber. Even small variations can dramatically affect material microstructure.

A typical specification for a quality furnace is a temperature uniformity of +/- 5°C. This ensures that every part of your component receives the same thermal treatment, preventing inconsistencies and defects in the final product.

The Role of Controllability and Stability

Controllability refers to how precisely the system can achieve and hold a target temperature. This is crucial for executing specific thermal profiles with ramps and soaks.

Modern furnaces achieve this using PID (Proportional-Integral-Derivative) loop control and SCR power regulation, often providing controllability of +/- 1°C. This stability ensures that your process is repeatable run after run.

Understanding the Key Trade-offs

Selecting a furnace involves balancing performance, complexity, and cost. Understanding the inherent trade-offs is critical for making an informed decision.

Higher Temperature vs. Cost and Complexity

As the maximum temperature rating increases, so do the cost and complexity of the furnace. Furnaces rated for 1700°C or 2000°C require more advanced heating elements, insulation, and power systems than a 1200°C model.

Multi-Zone Heating vs. Simplicity

Furnaces with multiple heating zones offer superior temperature uniformity across a larger volume. However, this comes at the cost of a more complex control system. For smaller components or less stringent uniformity requirements, a single-zone furnace may be more practical and cost-effective.

The Limit of a Low Vacuum Environment

While a low vacuum (-0.1 MPa) is excellent for preventing oxidation, it is not a high-vacuum environment. It is unsuitable for processes that are extremely sensitive to residual gases or require the deep vacuum levels used in the semiconductor or aerospace industries.

Making the Right Choice for Your Process

Your specific application should dictate your choice of furnace. Focus on the parameters that will most directly impact your desired outcome.

- If your primary focus is high-temperature sintering or processing advanced ceramics: Prioritize models specified for 1700°C or higher and confirm they offer excellent temperature uniformity.

- If your primary focus is annealing, tempering, or brazing common metals: A furnace in the 1000°C to 1400°C range is likely sufficient and will be a more economical choice.

- If your primary focus is process consistency and high-yield production: Pay closest attention to specifications for temperature uniformity (+/- 5°C or better) and controllability (+/- 1°C).

Ultimately, matching the furnace's complete performance profile—not just its peak temperature—to your material and process goals is the key to success.

Summary Table:

| Specification | Typical Range | Key Details |

|---|---|---|

| Maximum Temperature | 1000°C to 2000°C+ | Varies by model; common max is 1700°C for general use. |

| Vacuum Level | -0.1 MPa | Low vacuum to prevent oxidation, not for high-vacuum processes. |

| Temperature Uniformity | +/- 5°C | Ensures consistent heating across the chamber for reliable results. |

| Temperature Controllability | +/- 1°C | Achieved via PID control for precise, repeatable thermal profiles. |

| Applications | Sintering, annealing, brazing | Match temperature range to process needs (e.g., 1700°C+ for ceramics). |

Elevate your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering superior temperature control, uniformity, and repeatability for processes such as sintering and annealing. Don't settle for less—contact us today to discuss how we can optimize your heat treatment workflows and boost your research outcomes!

Visual Guide

Related Products

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

People Also Ask

- What are the key features of an atmosphere box furnace? Unlock Precise Heat Processing in Controlled Environments

- How does a batch type controlled atmosphere furnace operate? Master Precision Heat Treatment for Superior Materials

- What is inert gas technology used for in high-temperature atmosphere vacuum furnaces? Protect Materials and Speed Up Cooling

- How is the sealing performance of an experimental box type atmosphere furnace enhanced? Boost Purity with Advanced Sealing Systems

- How does the pressure range change under vacuum conditions in an atmosphere box furnace? Explore Key Shifts for Material Processing