Operationally, the Zirconia Dental Sintering Furnace is defined by its speed, precision, and user-friendliness. These furnaces combine a rapid 25-minute sintering cycle with extremely tight temperature control and an intuitive touch screen interface. This allows dental labs and clinics to produce high-strength, accurate zirconia restorations with remarkable efficiency and consistency.

The core value of a modern Zirconia Sintering Furnace is not just one feature, but the integration of automated controls, rapid heating, and precise thermal management. This transforms the production of dental restorations from a lengthy, manual process into a fast, reliable, and repeatable workflow.

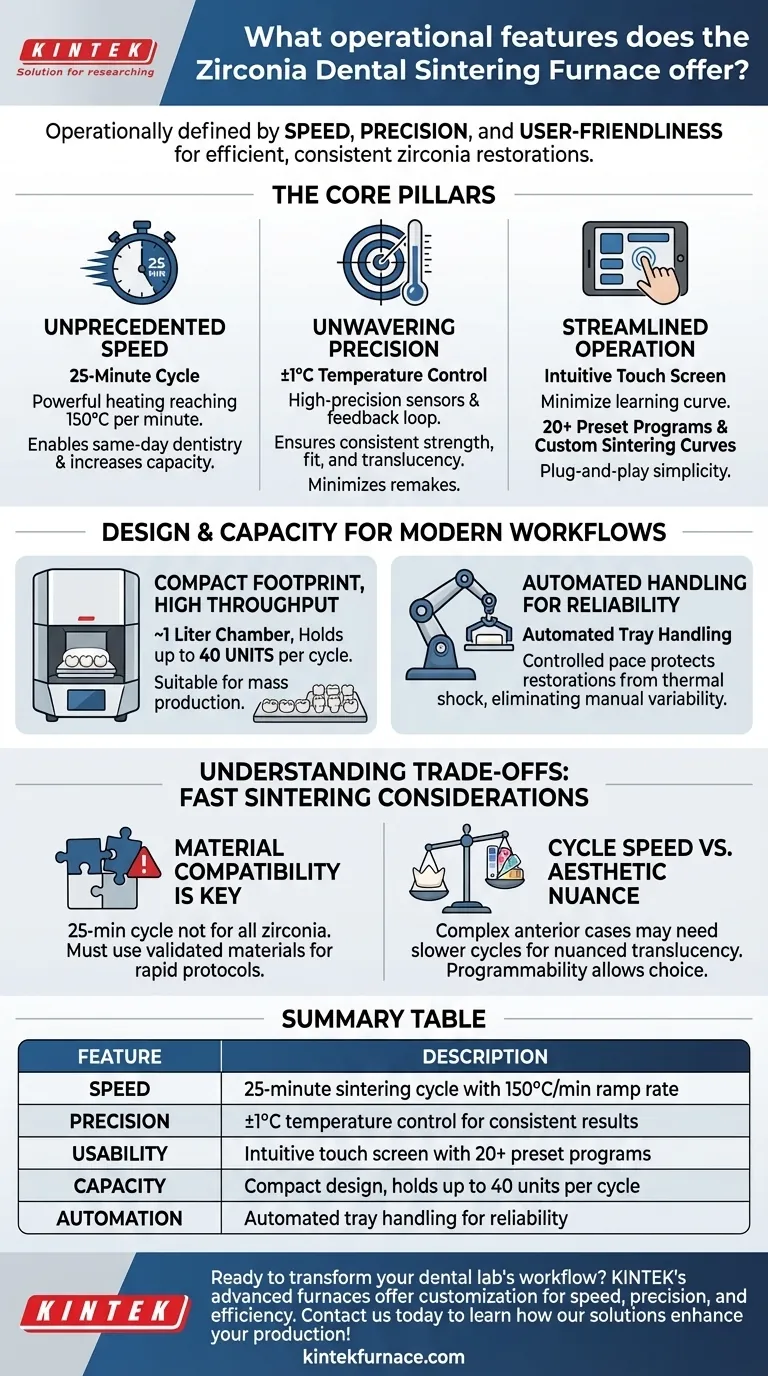

The Core Pillars: Speed, Precision, and Usability

The operational benefits of these furnaces are built on three fundamental capabilities. Understanding how they work together is key to appreciating their impact on a dental lab's output.

Unprecedented Speed: The 25-Minute Cycle

The most significant operational feature is the ability to complete a full sintering cycle in as little as 25 minutes.

This is made possible by a powerful heating system capable of reaching ramp rates of 150°C per minute. This speed directly enables same-day dentistry and dramatically increases a lab's daily production capacity.

Unwavering Precision: Consistency in Every Restoration

To achieve predictable results, the furnace maintains exceptionally stable temperatures. High-precision sensors and an automatic feedback loop keep thermal fluctuations within ±1°C.

This level of control is critical for ensuring the final restoration has the correct strength, fit, and translucency. It minimizes the risk of internal stresses or micro-fractures, leading to fewer remakes.

Streamlined Operation: The Intuitive Interface

The furnace is operated via an intuitive touch screen control panel, designed to minimize the learning curve and reduce operator error.

It comes with up to 20 preset programs for common zirconia materials, but also allows technicians to easily create and save custom sintering curves. This provides both "plug-and-play" simplicity and the flexibility needed for specialized materials or research.

Design and Capacity for Modern Workflows

The physical design is engineered to support efficient, high-volume production within the space constraints of a typical lab or clinic.

Compact Footprint, High Throughput

Despite its speed, the furnace features a compact muffle chamber with a volume of approximately one liter.

This chamber is designed to maximize capacity, accommodating around 40 individual units at once. This combination of a small physical footprint and high throughput makes it suitable for mass production.

Automated Handling for Reliability

Many models include automated tray handling. The furnace automatically raises and lowers the sintering tray into the chamber at a controlled pace.

This automation ensures a smooth, consistent process, protecting restorations from potential thermal shock and eliminating variability from manual handling.

Understanding the Trade-offs: Fast Sintering Considerations

While the benefits are substantial, it is crucial to understand the context in which these features operate best. Speed is not the only factor in a quality restoration.

Material Compatibility is Key

The ultra-fast 25-minute cycle is not compatible with all zirconia materials on the market. Always verify that your chosen zirconia block is validated by its manufacturer for rapid or speed sintering protocols.

Using a non-validated material in a fast cycle can compromise the final mechanical properties and aesthetic outcome of the restoration.

Cycle Speed vs. Aesthetic Nuance

For highly complex anterior cases requiring maximum aesthetic characterization, some expert technicians may still prefer a slower, traditional sintering cycle.

Longer cycles can sometimes provide more nuanced control over the translucency gradients in multi-layered zirconia. The furnace's programmability allows you to make this choice based on the specific clinical and aesthetic demands of the case.

Making the Right Choice for Your Goal

The operational features of a Zirconia Sintering Furnace should be matched to your primary objective.

- If your primary focus is high-volume production or same-day dentistry: The 25-minute cycle, 40-unit capacity, and automated handling are the most critical features for maximizing throughput.

- If your primary focus is material research or a specialty cosmetic lab: The ability to create custom heating curves and the ±1°C precision are essential for testing new materials and achieving specific, repeatable aesthetic results.

- If your primary focus is integrating an efficient in-house workflow: The simple touch screen interface and 20 preset programs provide a reliable, easy-to-use system that minimizes training and operator error.

Ultimately, these furnaces empower you to deliver consistent, high-quality restorations on a dramatically accelerated timeline.

Summary Table:

| Feature | Description |

|---|---|

| Speed | 25-minute sintering cycle with 150°C/min ramp rate |

| Precision | ±1°C temperature control for consistent results |

| Usability | Intuitive touch screen with 20+ preset programs |

| Capacity | Compact design, holds up to 40 units per cycle |

| Automation | Automated tray handling for reliability |

Ready to transform your dental lab's workflow? KINTEK's advanced high-temperature furnaces, including specialized sintering models, offer deep customization to meet your unique needs for speed, precision, and efficiency. Contact us today to learn how our solutions can enhance your production of high-strength zirconia restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Spark Plasma Sintering SPS Furnace

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns