To answer your question directly, dental zirconia sintering furnaces are equipped with multiple language options to accommodate a global user base. This feature ensures that dental technicians from various regions can operate the equipment safely and effectively in their native language.

The availability of multiple languages is more than a convenience; it is a critical feature for ensuring operational precision, reducing user error, and maximizing the advanced capabilities of the sintering furnace.

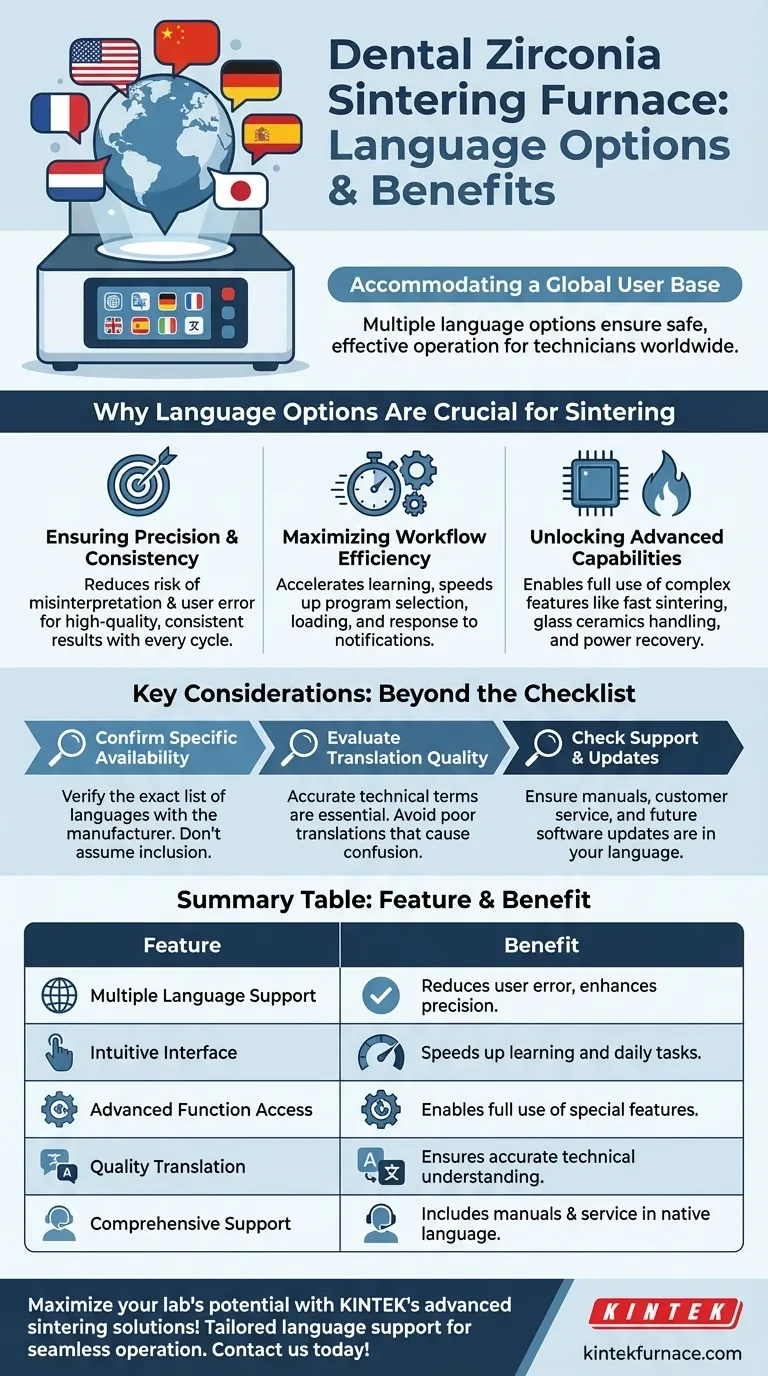

Why Language Options Are Crucial for Sintering Operations

The primary function of a zirconia sintering furnace is to execute highly precise heating cycles. A language barrier can directly compromise the quality of the final dental restoration.

Ensuring Precision and Consistency

Sintering requires exact temperature control and timing to achieve the desired material densification and aesthetic properties.

Instructions, alerts, and programming menus in a familiar language significantly reduce the risk of misinterpretation and user error. This is essential for achieving consistent, high-quality results with every cycle.

Maximizing Workflow Efficiency

An intuitive interface in a technician's native language accelerates the learning curve for new equipment.

It also speeds up daily tasks like selecting a sintering program, loading the furnace, and responding to system notifications. This directly enhances lab productivity and reduces operational downtime.

Unlocking Advanced Furnace Capabilities

Modern furnaces include valuable features like fast sintering cycles, the ability to handle glass ceramics, and power interruption recovery.

Effectively using these advanced functions often requires navigating complex settings menus. A clear interface in the user's language ensures your team can leverage these features to their full potential, maximizing your return on investment.

Key Considerations Beyond a Simple Checklist

While the availability of multiple languages is a positive indicator, you must dig deeper to ensure it meets your lab's specific needs.

Confirming Specific Language Availability

The term "multiple languages" is vague. The most critical step is to verify the exact list of available languages with the manufacturer or your equipment supplier before making a purchase.

Do not assume your required language is included. Always ask for explicit confirmation.

Evaluating the Quality of Translation

A poor or incomplete translation can be more confusing than no translation at all. Technical terms must be translated accurately to avoid critical misunderstandings.

If possible, request a virtual demonstration of the software interface or look for reviews from users in your region to gauge the quality of the localization.

Support and Future Updates

Language support should extend beyond the furnace's user interface. Confirm whether technical documentation, user manuals, and customer support are also available in your preferred language.

Additionally, inquire if future software updates will continue to support the full range of languages.

Making the Right Choice for Your Lab

Choosing the right equipment involves ensuring it integrates seamlessly into your specific operational environment.

- If your primary focus is immediate usability for a multilingual team: Make direct confirmation of your specific language requirements your top priority in the evaluation process.

- If your primary focus is long-term reliability and support: Ensure that comprehensive support, including technical documents and customer service, is available in your team's native language.

Ultimately, selecting a furnace with the right language support empowers your team to produce exceptional dental restorations with confidence and precision.

Summary Table:

| Feature | Benefit |

|---|---|

| Multiple Language Support | Reduces user error and enhances operational precision |

| Intuitive Interface | Speeds up learning and daily tasks for better efficiency |

| Advanced Function Access | Enables full use of features like fast sintering and power recovery |

| Quality Translation | Ensures accurate understanding of technical terms |

| Comprehensive Support | Includes manuals and customer service in native languages |

Maximize your lab's potential with KINTEK's advanced sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace options like Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we meet your unique experimental needs, including tailored language support for seamless operation. Contact us today to enhance precision, efficiency, and ROI in your dental restorations!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Spark Plasma Sintering SPS Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- What are the recommended maintenance practices for dental furnaces? Ensure Precision and Longevity for Your Lab

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations