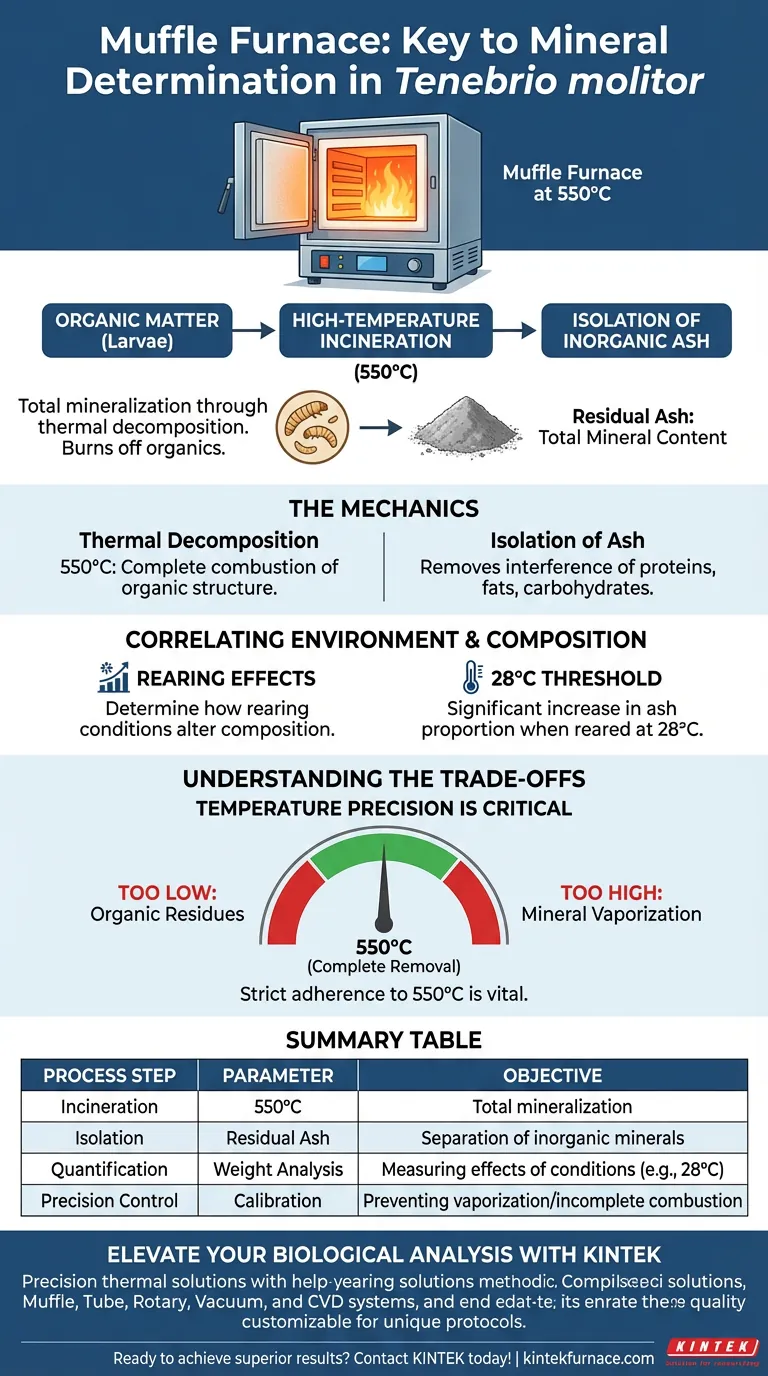

The key step performed by a Muffle Furnace in this analysis is the total mineralization of Tenebrio molitor larvae through high-temperature incineration. By maintaining a constant environment of 550 °C, the furnace effectively burns off all organic matter, isolating the residual ash required for accurate mineral quantification.

To accurately measure mineral content, you must eliminate organic interference. The Muffle Furnace achieves this by incinerating samples at 550 °C, separating the inorganic ash to reveal how environmental factors, such as rearing temperature, influence mineral accumulation.

The Mechanics of Mineralization

Thermal Decomposition

The Muffle Furnace creates a thermal environment that carbon-based biological tissues cannot withstand. By sustaining a temperature of 550 °C, the equipment ensures the complete combustion of the larvae's organic structure.

Isolation of Inorganic Ash

The goal of this high heat is to reduce the complex biological sample down to its elemental base. Once the organic matter is removed, only the residual ash remains. This ash represents the total mineral content of the sample, free from the interference of proteins, fats, or carbohydrates.

correlating Environment to Composition

Quantifying Rearing Effects

This mineralization step is critical for comparative biological studies. Researchers use the resulting ash data to determine how external rearing conditions alter the internal composition of the larvae.

The 28 °C Threshold

Specific studies utilize this method to track physiological changes based on temperature. For example, evidence shows a significant increase in ash proportion (mineral content) when Tenebrio molitor larvae are reared at temperatures reaching 28 °C. Without the precise ashing provided by the furnace, this correlation would be impossible to isolate.

Understanding the Trade-offs

Temperature Precision is Critical

While the Muffle Furnace is a robust tool, it requires strict adherence to the 550 °C standard for this specific organism. If the temperature is set too low, organic residues will remain, artificially inflating the weight of the "mineral" content. Conversely, excessively high temperatures could cause volatile minerals to vaporize, leading to an underestimation of the total mineral content.

Making the Right Choice for Your Analysis

- If your primary focus is protocol standardization: Ensure your furnace is calibrated to exactly 550 °C to guarantee the complete removal of organic matter without compromising the inorganic matrix.

- If your primary focus is nutritional profiling: Use the ash content data specifically to evaluate how environmental variables, such as a 28 °C rearing temperature, enhance or deplete the mineral density of the larvae.

Precision in thermal processing is the only way to transform a biological sample into actionable chemical data.

Summary Table:

| Process Step | Parameter | Objective |

|---|---|---|

| Incineration | 550 °C | Total mineralization of organic matter |

| Isolation | Residual Ash | Separation of inorganic minerals from fats/proteins |

| Quantification | Weight Analysis | Measuring effects of rearing conditions (e.g., 28 °C) |

| Precision Control | Calibration | Preventing mineral vaporization or incomplete combustion |

Elevate Your Biological Analysis with KINTEK

Precision is paramount when transforming biological samples into actionable chemical data. KINTEK provides industry-leading thermal solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all engineered to maintain the strict temperature tolerances required for accurate ash determination and mineral profiling. Backed by expert R&D and manufacturing, our high-temp lab furnaces are fully customizable to meet your unique research protocols.

Ready to achieve superior mineralization results? Contact KINTEK today to discuss your laboratory needs!

Visual Guide

References

- Anežka Kopecká, Martin Kulma. Effect of Temperature on the Nutritional Quality and Growth Parameters of Yellow Mealworm (Tenebrio molitor L.): A Preliminary Study. DOI: 10.3390/app14062610

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages of using a muffle furnace for catalyst recalcination? Achieve Full Structural Regeneration

- What precautions should be taken when handling items inside the muffle furnace? Ensure Safety and Protect Your Equipment

- What are the typical technical specifications of muffle furnaces? Key Features for High-Temp Precision

- What is the purpose of using a high-temperature furnace at 900°C for eggshells? Master Calcination for CaO Production

- What are the advantages and disadvantages of muffle furnaces? Achieve Contaminant-Free Heating for Sensitive Applications

- What is the role of muffle furnaces in incineration processes? Precision Ashing for Accurate Material Analysis

- What temperature ranges are used for different muffle furnace applications? Optimize Your Heat Processes with KINTEK

- How is a muffle furnace applied to determine glass fiber content in GFPP? Precision Calcination Explained