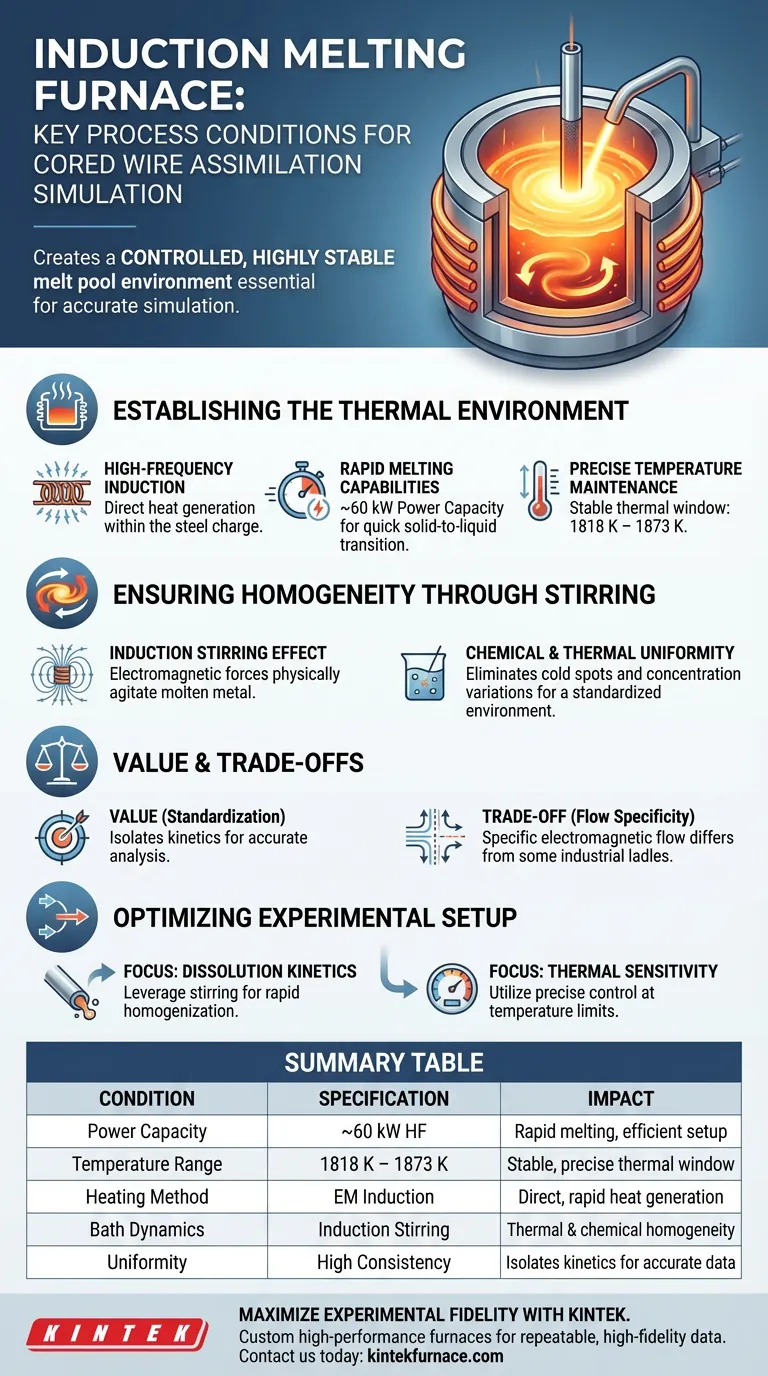

The induction melting furnace establishes a controlled, highly stable melt pool environment essential for cored wire assimilation simulations. Through high-frequency electromagnetic induction and substantial power capacities (typically around 60 kW), it ensures rapid steel melting, precise temperature maintenance between 1818 K and 1873 K, and rigorous bath uniformity via inherent induction stirring.

The primary value of an induction melting furnace in these experiments is the creation of a standardized physical environment. By combining precise thermal control with electromagnetic stirring, it eliminates variables in temperature and chemical composition, effectively isolating the kinetics of cored wire dissolution for accurate analysis.

Establishing the Thermal Environment

High-Frequency Electromagnetic Induction

The furnace utilizes high-frequency electromagnetic induction as its primary heating mechanism. This method allows for the rapid generation of heat directly within the steel charge, rather than relying on external heat transfer.

Rapid Melting Capabilities

With power capacities often reaching 60 kW, the furnace facilitates the quick transition of steel from solid to liquid. This efficiency reduces the preparation time required to reach the experimental baseline.

Precise Temperature Maintenance

Once the steel is molten, the furnace maintains specific experimental temperatures with high precision. It creates a stable thermal window, typically between 1818 K and 1873 K.

This stability is critical for simulation accuracy, as it ensures the cored wire is subjected to consistent thermal stress during assimilation.

Ensuring Homogeneity Through Stirring

The Induction Stirring Effect

A key feature of this process is the electromagnetic stirring effect inherent to induction heating. The magnetic field generates forces that physically agitate the molten metal.

Achieving Chemical and Thermal Uniformity

This continuous stirring ensures that both temperature and chemical composition are uniform throughout the bath.

By eliminating cold spots or areas of varying chemical concentration, the furnace establishes a standardized physical environment. This uniformity allows researchers to attribute experimental results directly to the properties of the cored wire, rather than inconsistencies in the melt pool.

Understanding the Operational Trade-offs

Flow Pattern Specificity

While induction stirring provides excellent uniformity, it generates specific flow patterns driven by electromagnetic forces.

Simulation vs. Industrial Reality

These flow dynamics creates a highly controlled kinetic environment. However, researchers should note that these specific stirring patterns may differ slightly from the fluid dynamics found in gas-stirred or mechanically stirred industrial ladles.

Optimizing Your Experimental Setup

To maximize the validity of your cored wire assimilation data, align the furnace capabilities with your specific research goals:

- If your primary focus is dissolution kinetics: Rely on the induction stirring effect to minimize boundary layer resistance and ensure rapid homogenization of the dissolved wire.

- If your primary focus is thermal sensitivity: Utilize the strict temperature control (1818 K – 1873 K) to test wire performance at the exact upper and lower limits of your target processing window.

Leveraging the induction furnace’s ability to standardize the melt pool is the most effective way to produce repeatable, high-fidelity experimental data.

Summary Table:

| Condition | Specification/Feature | Impact on Simulation |

|---|---|---|

| Power Capacity | ~60 kW High-Frequency | Enables rapid melting and efficient setup |

| Temperature Range | 1818 K to 1873 K | Provides a stable, precise thermal window |

| Heating Method | Electromagnetic Induction | Direct heat generation for rapid transitions |

| Bath Dynamics | Induction Stirring Effect | Ensures thermal and chemical homogeneity |

| Uniformity | High Consistency | Isolates kinetics for accurate data analysis |

Maximize Experimental Fidelity with KINTEK

Ensure your cored wire assimilation simulations are backed by industry-leading precision. KINTEK provides high-performance induction melting systems, Muffle, Tube, and Vacuum furnaces—all backed by expert R&D and manufacturing. Our systems are fully customizable to meet your specific research temperatures and stirring requirements, ensuring repeatable, high-fidelity data every time.

Ready to optimize your lab’s thermal processing? Contact KINTEK today to discuss your unique needs

Visual Guide

References

- Edgar Ivan Castro Cedeño, Alain Jardy. Study of Assimilation of Cored Wire into Liquid Steel Baths. DOI: 10.3390/met14040462

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- What are the advantages of an Induction Cold Crucible Furnace (ICCF) for Nb-MASC? Achieve Ultimate High-Purity Melting

- What role does a vacuum arc melting furnace play in the initial preparation of CrMnFeCoNi high-entropy alloys?

- Why is a quartz tube preferred as the reactor body in induction heating? Maximize Efficiency & Energy Focus

- What role does vacuum induction melting equipment play in the preparation of CrFeNi alloys? Essential Purity Guide

- What are the advantages of using a Vacuum Induction Melting furnace for Cr-Si alloys? Superior Uniformity & Purity

- What are the primary industrial applications of induction furnaces? Unlock Efficient Metal Processing Solutions

- What is the role of a vacuum induction furnace in CuNiSiCrCoTiNbx synthesis? Ensure Purity & Homogeneity

- What role does a medium frequency induction furnace play in GGG60 production? Ensure Superior Metallurgical Quality