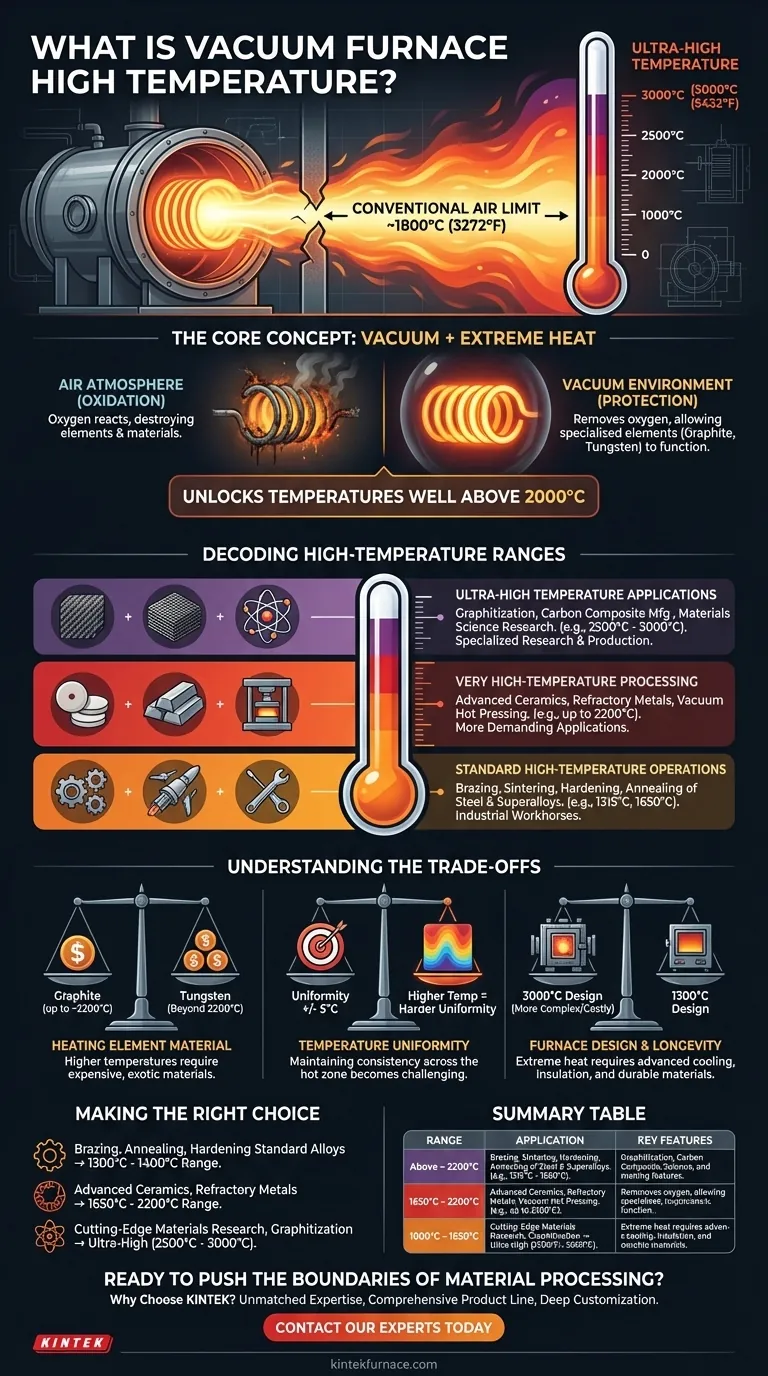

In a vacuum furnace, "high temperature" refers to a range extending far beyond what is possible in an open-air atmosphere, typically starting where conventional furnaces fail around 1800°C (3272°F). Depending on the specific design and heating elements used, these furnaces can achieve controlled temperatures up to 3000°C (5432°F) for advanced material processing.

The core concept is not just about generating heat, but about creating an environment—a vacuum—that prevents the heating elements and the processed materials from oxidizing and burning away at extreme temperatures. This is the key that unlocks temperatures well above 2000°C.

The Fundamental Principle: Why a Vacuum Is Essential

To understand "high temperature" in this context, you must first understand why the vacuum is non-negotiable. It solves a fundamental problem of physics and chemistry at extreme heat.

Preventing Oxidation at High Temperatures

In a normal atmosphere, oxygen acts as an aggressive agent. At very high temperatures, it will rapidly react with and destroy most materials, including the very heating elements designed to generate the heat.

A vacuum furnace removes the oxygen and other reactive gases. By creating this non-oxidizing environment, it allows materials to be heated to their limits without being consumed by chemical reactions.

Enabling Specialized Heating Elements

Standard resistance heating elements used in air max out around 1800°C before failing.

Vacuum furnaces utilize specialized heating elements made from materials like graphite, molybdenum, or tungsten. These materials can operate at incredibly high temperatures but would be destroyed instantly if exposed to oxygen at that heat. The vacuum protects them, enabling them to function.

Decoding High-Temperature Ranges

"High temperature" isn't a single number but a series of tiers, each defined by different furnace capabilities and intended for specific applications.

Standard High-Temperature Operations (1000°C – 1650°C)

This is the most common range for industrial vacuum furnaces. It is used for processes like brazing, sintering, hardening, and annealing of steel and superalloys.

Furnaces in this category, often specified up to 1315°C (2400°F) or 1650°C (3000°F), are the workhorses of the aerospace, medical, and tool manufacturing industries.

Very High-Temperature Processing (1650°C – 2200°C)

This range is required for more demanding applications. It is essential for processing advanced ceramics, refractory metals, and certain types of sintering that require more thermal energy.

A vacuum hot press, for example, might operate up to 2200°C (3992°F) to simultaneously heat and press materials into dense, high-performance parts.

Ultra-High Temperature Applications (Above 2200°C)

Reaching temperatures of 2200°C to 3000°C (5432°F) is the domain of highly specialized research and production furnaces.

These are used for graphitization, carbon composite manufacturing, and materials science research where the absolute thermal limits of elements need to be explored.

Understanding the Trade-offs

Achieving higher temperatures is not simply a matter of turning up the power. It involves significant engineering trade-offs that impact cost, complexity, and performance.

Heating Element Material

The choice of heating element directly dictates the maximum temperature. Graphite is common and cost-effective for temperatures up to around 2200°C.

For temperatures beyond that, more expensive and exotic materials like tungsten are required, significantly increasing the furnace's cost and complexity.

Temperature Uniformity

As the temperature climbs, it becomes harder to maintain perfect uniformity across the entire hot zone. Even the best furnaces must balance peak temperature with consistency.

A nominal temperature uniformity of +/- 5°C, as is sometimes specified, is considered excellent for high-temperature processes and requires sophisticated zone control and power regulation.

Furnace Design and Longevity

Extreme heat puts immense stress on every component, from insulation to the vacuum chamber walls. Furnaces designed for 3000°C require more robust insulation, advanced cooling systems, and more durable materials throughout, making them far more complex and expensive to build and maintain than a 1300°C furnace.

Making the Right Choice for Your Application

Selecting a furnace is about matching its temperature capability to your specific material and process goal.

- If your primary focus is brazing, annealing, or hardening standard alloys: A furnace capable of 1300°C to 1400°C provides the necessary heat without the cost of higher-temperature systems.

- If your primary focus is processing advanced ceramics or refractory metals: You will need to look at systems rated for at least 1650°C and potentially as high as 2200°C.

- If your primary focus is cutting-edge materials research or graphitization: Your work demands an ultra-high temperature furnace, where reaching 2500°C to 3000°C is the critical requirement.

Ultimately, the temperature specification of a vacuum furnace is a direct reflection of the sophisticated problems it is engineered to solve.

Summary Table:

| Temperature Range | Typical Applications | Key Features |

|---|---|---|

| 1000°C – 1650°C | Brazing, sintering, hardening of steel & superalloys | Industrial workhorse, cost-effective |

| 1650°C – 2200°C | Advanced ceramics, refractory metals processing | High-performance, specialized heating elements |

| Above 2200°C | Graphitization, carbon composites, materials research | Ultra-high temperature, exotic materials required |

Ready to Push the Boundaries of Material Processing?

Whether your application requires precise heat treatment at 1300°C or cutting-edge research at 3000°C, KINTEK's advanced high-temperature vacuum furnaces are engineered to meet your exact needs.

Why Choose KINTEK?

- Unmatched Expertise: Leveraging exceptional R&D and in-house manufacturing, we deliver robust solutions for laboratories in aerospace, medical, and advanced materials sectors.

- Comprehensive Product Line: From Muffle and Tube Furnaces to specialized Vacuum & Atmosphere Furnaces and CVD/PECVD Systems, we have the right tool for your high-temperature challenges.

- Deep Customization: Our strong engineering capability ensures your furnace is tailored to your unique process requirements, temperature uniformity specs, and material goals.

Don't let temperature limitations hold back your innovation. Contact our experts today to discuss how a KINTEK vacuum furnace can transform your high-temperature processing capabilities.

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Hot Press Furnace Machine Heated Vacuum Press Tube Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the benefits of vacuum heat treatment? Achieve Superior Metallurgical Control

- How does a vacuum heat treatment furnace influence Ti-6Al-4V microstructure? Optimize Ductility and Fatigue Resistance

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance