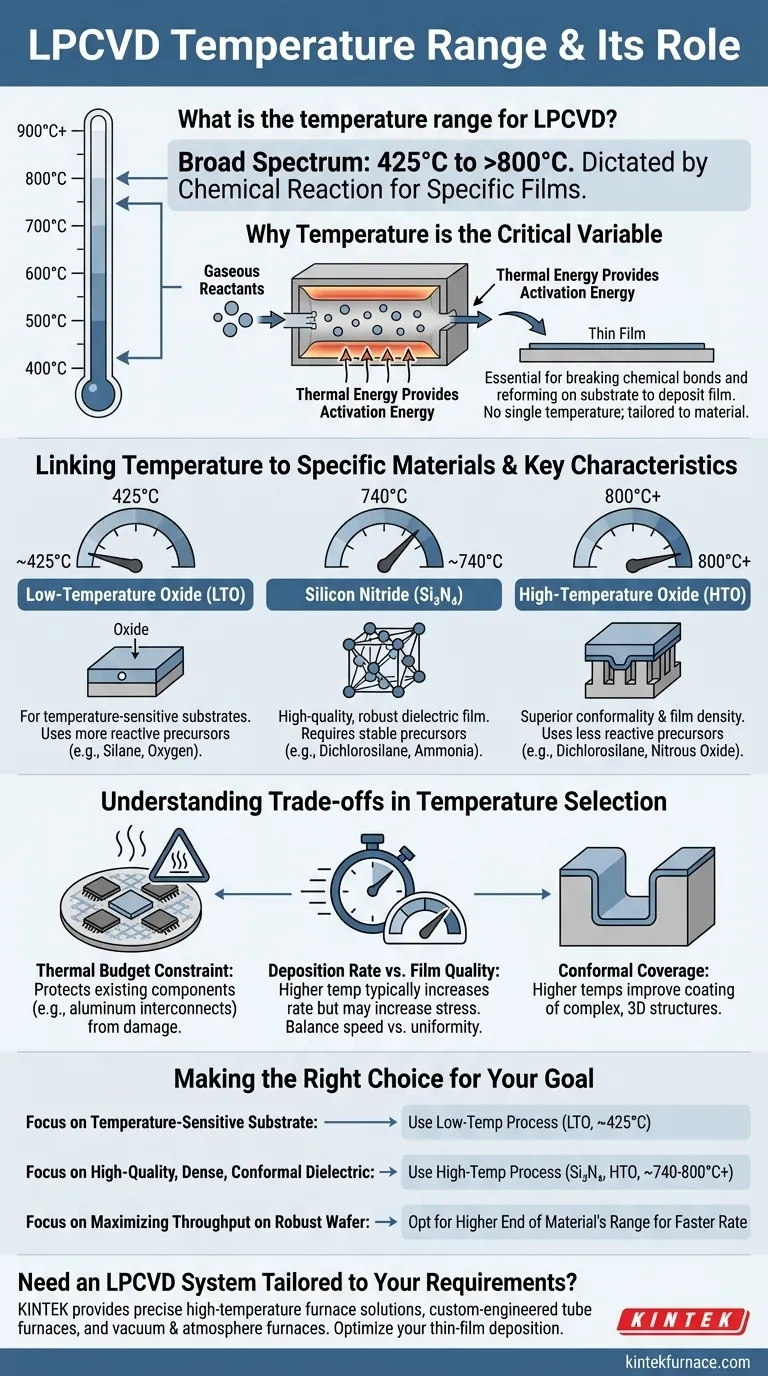

In short, LPCVD processes operate within a broad temperature range, typically from as low as 425°C to well over 800°C. This wide spectrum is not arbitrary; the precise temperature is dictated by the specific chemical reaction required to deposit a particular thin film, such as silicon dioxide or silicon nitride.

The specific temperature for an LPCVD process is not a general setting but a critical parameter tied directly to the chemistry needed to form the desired thin film. Different materials have unique deposition reactions that only activate at distinct temperature thresholds, influencing the entire manufacturing process.

Why Temperature is the Critical Variable in LPCVD

Low-Pressure Chemical Vapor Deposition (LPCVD) is a process that builds a solid thin film on a substrate from gaseous reactants. Temperature is the primary lever that controls this chemical transformation.

The Role of Thermal Energy

Temperature provides the activation energy needed for the precursor gases to react. Without sufficient thermal energy, the chemical bonds in the gas molecules will not break and reform on the substrate surface, and no film will be deposited.

Each chemical reaction has a unique energy requirement, which is why there is no single temperature for "LPCVD." The process is always tailored to the material.

Linking Temperature to Specific Materials

The required temperature is a direct function of the film being created. The stability of the precursor gases and the desired reaction pathway determine the necessary heat.

-

Low-Temperature Oxide (LTO): Deposited around 425°C, LTO is a form of silicon dioxide. This lower temperature is possible by using more reactive precursors (e.g., silane and oxygen), which require less energy to form a film.

-

Silicon Nitride: This robust dielectric material requires a much higher temperature, typically around 740°C. The precursor gases used (e.g., dichlorosilane and ammonia) are more stable and need significantly more thermal energy to react and form a high-quality Si₃N₄ film.

-

High-Temperature Oxide (HTO): Requiring temperatures of 800°C or higher, HTO is another form of silicon dioxide. Unlike LTO, it uses less reactive precursors (e.g., dichlorosilane and nitrous oxide), resulting in a higher-quality, more conformal film at the cost of a much higher thermal load.

Understanding the Trade-offs of Temperature Selection

Choosing a temperature is not just about enabling a chemical reaction; it's a critical decision with major implications for the entire device fabrication sequence.

The Thermal Budget Constraint

The most significant constraint is the thermal budget of the wafer. Components already fabricated on the substrate, such as aluminum interconnects or precisely doped regions, can be damaged or altered by excessive heat.

A high-temperature step performed late in the manufacturing flow can ruin a device. This is precisely why processes like LTO were developed—to enable oxide deposition without exceeding the thermal limits of other components.

Deposition Rate vs. Film Quality

Generally, a higher temperature within a material's process window leads to a faster deposition rate. This increases manufacturing throughput.

However, higher temperatures can also increase mechanical stress within the deposited film. The choice often involves balancing the need for speed against the need for a low-stress, highly uniform, and dense film. HTO, for example, is slower than some methods but produces a superior quality film for critical applications.

Conformal Coverage

Higher temperatures often improve the ability of a film to coat complex, three-dimensional structures uniformly—a property known as conformality. The increased surface mobility of reactive species at higher temperatures allows them to cover vertical sidewalls and trenches more effectively.

Making the Right Choice for Your Goal

The ideal LPCVD temperature is determined by your material requirements, film quality specifications, and overall process constraints.

- If your primary focus is depositing on a temperature-sensitive substrate: You must use a low-temperature process, such as LTO around 425°C, to avoid damaging underlying device layers.

- If your primary focus is creating a high-quality, dense, and conformal dielectric: A high-temperature process, like silicon nitride (~740°C) or HTO (>800°C), is often required to achieve the necessary film properties.

- If your primary focus is maximizing throughput on a thermally robust wafer: Opting for the higher end of a material's acceptable temperature range can significantly increase the deposition rate.

Ultimately, selecting the correct LPCVD temperature is a calculated decision that balances the chemistry of the desired film with the physical limitations of your device.

Summary Table:

| Material | Typical LPCVD Temperature | Key Characteristics |

|---|---|---|

| Low-Temperature Oxide (LTO) | ~425°C | For temperature-sensitive substrates, uses reactive precursors (e.g., Silane). |

| Silicon Nitride (Si₃N₄) | ~740°C | High-quality, robust dielectric film; requires stable precursors. |

| High-Temperature Oxide (HTO) | 800°C+ | Superior conformality and film density; less reactive precursors. |

Need an LPCVD System Tailored to Your Specific Temperature and Material Requirements?

Selecting the correct LPCVD temperature is critical for your film's quality and device integrity. KINTEK's expertise in advanced thermal processing can help you navigate these complex trade-offs.

We provide the precise high-temperature furnace solutions you need:

- Custom-Engineered Tube Furnaces: Ideal for precise LPCVD processes, designed to meet your exact temperature range and uniformity requirements.

- Vacuum & Atmosphere Furnaces: For processes requiring controlled environments at high temperatures.

- Deep Customization: Leveraging our in-house R&D and manufacturing, we adapt our systems—whether for Silicon Nitride at 740°C or LTO at 425°C—to your unique experimental and production goals.

Let's optimize your thin-film deposition process. Contact our experts today to discuss how our solutions can enhance your research and manufacturing outcomes.

Visual Guide

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How are hexagonal boron nitride (h-BN) films processed using CVD tube furnaces? Optimize Growth for High-Quality 2D Materials

- What are the key features of CVD tube-furnace systems? Unlock Precise Thin-Film Deposition

- How can integrating CVD tube furnaces with other technologies benefit device fabrication? Unlock Advanced Hybrid Processes

- How does CVD tube furnace sintering enhance graphene growth? Achieve Superior Crystallinity and High Electron Mobility

- What is tube CVD? A Guide to High-Purity Thin Film Synthesis