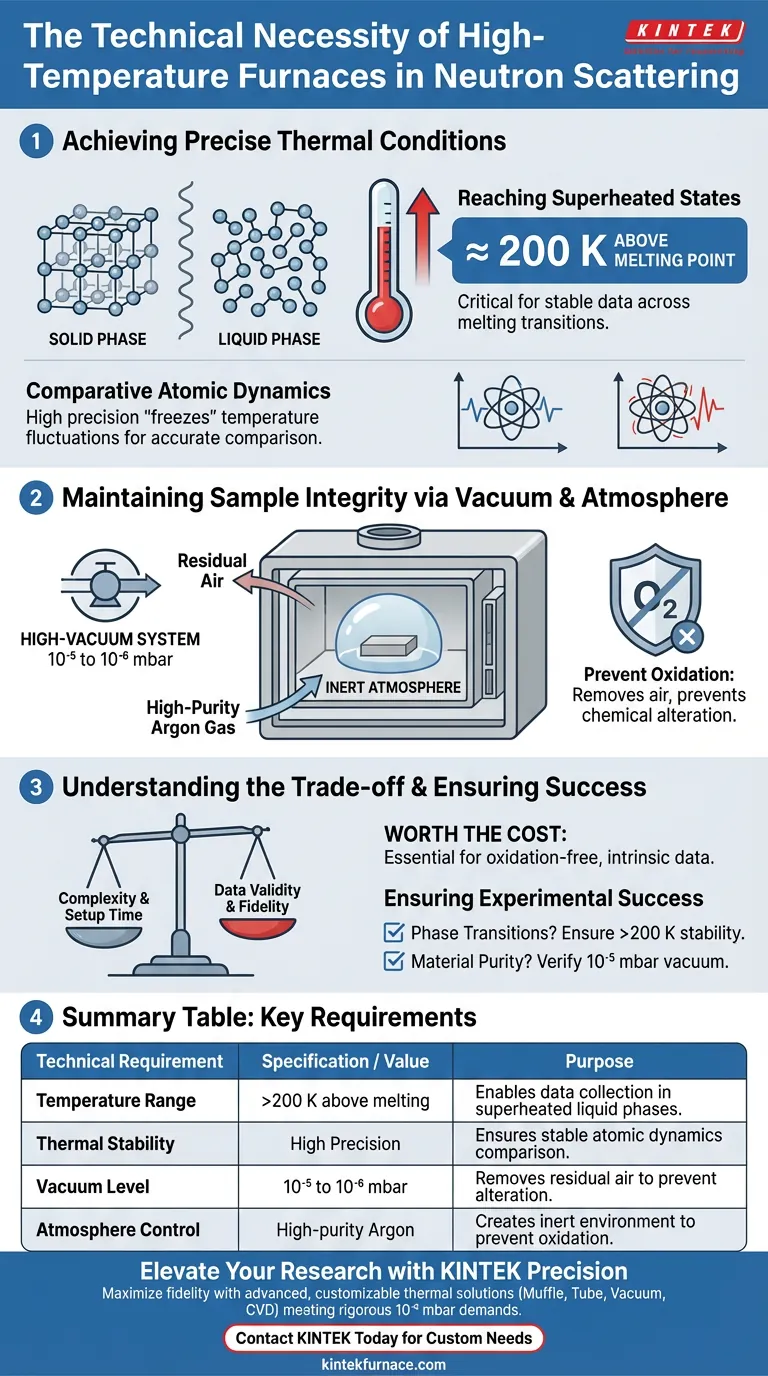

The technical necessity of high-temperature furnaces in neutron scattering lies in their ability to provide a strictly controlled thermal environment capable of heating metal samples approximately 200 K above their melting points. This capability is critical for collecting stable data at specific temperature points in both solid and liquid phases, enabling the accurate comparison of atomic dynamics across the melting transition.

High-temperature furnaces are not merely heating elements; they are precision instruments that isolate the sample from environmental variables. By combining extreme heat with high-vacuum conditions, they ensure that the atomic movements observed are intrinsic to the material's phase change, rather than artifacts of oxidation or thermal instability.

Achieving Precise Thermal Conditions

Reaching Superheated States

To fully understand the behavior of metals, researchers must observe them well beyond the point of liquefaction.

A standard furnace cannot simply reach the melting point; it must be capable of stably holding the sample at temperatures roughly 200 K above the melting point.

Comparative Atomic Dynamics

The primary scientific goal is often to compare how atoms move in a rigid solid lattice versus a fluid liquid state.

To do this accurately, data must be collected at specific, stable temperature plateaus. High-temperature furnaces provide the thermal stability required to "freeze" the temperature variable, ensuring the gathered neutron scattering data reflects true atomic dynamics rather than temperature fluctuations.

Maintaining Sample Integrity via Vacuum

The Role of High-Vacuum Systems

Heat alone is insufficient; the environment must be pristine to prevent chemical alteration of the sample.

Advanced furnaces are equipped with high-vacuum systems capable of reaching pressures between 10⁻⁵ and 10⁻⁶ mbar. This removes residual air from the chamber prior to the heating phase.

Preventing Oxidation

At high temperatures, metals are highly reactive and prone to oxidation, which ruins the sample and invalidates the scattering data.

By evacuating air and introducing high-purity argon gas, the system creates an inert atmosphere. This prevents atmospheric oxygen from interfering with the metal, ensuring that the chemical composition remains pure throughout the experiment.

Understanding the Trade-offs

Complexity vs. Data Fidelity

Using such sophisticated equipment increases the complexity of the experimental setup significantly.

Achieving high-vacuum conditions requires rigorous preparation and creates a longer setup time compared to ambient heating. However, this "cost" in time and complexity is the necessary trade-off for data validity; without it, surface oxidation would dominate the signal, obscuring the atomic dynamics you intend to measure.

Ensuring Experimental Success

To ensure your neutron scattering experiment yields valid results, prioritize your equipment capabilities based on your specific scientific goals:

- If your primary focus is studying phase transitions: Ensure your furnace specifications allow for stable thermal control at least 200 K above the theoretical melting point of your sample.

- If your primary focus is material purity and surface chemistry: Verify that the furnace integrates a high-vacuum system capable of 10⁻⁵ mbar or better to eliminate atmospheric contamination.

By controlling both temperature and atmosphere, you transform a chaotic heating process into a precise, quantifiable scientific measurement.

Summary Table:

| Technical Requirement | Specification / Value | Purpose in Neutron Scattering |

|---|---|---|

| Temperature Range | >200 K above melting point | Enables data collection in superheated liquid phases. |

| Thermal Stability | High Precision | Ensures stable atomic dynamics comparison across transitions. |

| Vacuum Level | $10^{-5}$ to $10^{-6}$ mbar | Removes residual air to prevent chemical alteration. |

| Atmosphere Control | High-purity Argon gas | Creates an inert environment to prevent sample oxidation. |

Elevate Your Research with KINTEK Precision

Maximize the fidelity of your neutron scattering data with KINTEK’s advanced thermal solutions. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to meet the rigorous demands of high-temperature research. Our furnaces provide the $10^{-6}$ mbar vacuum levels and extreme thermal stability required to prevent oxidation and ensure precise atomic dynamics measurements.

Ready to optimize your lab's high-temperature capabilities? Contact KINTEK today to discuss your custom furnace needs

Visual Guide

References

- C. M. Bernal-Choban, Brent Fultz. Atomistic origin of the entropy of melting from inelastic neutron scattering and machine learned molecular dynamics. DOI: 10.1038/s43246-024-00695-x

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the main applications of a box muffle furnace in material research? Unlock Precision Heat Treatment and Analysis

- What is the function of Muffle Furnaces in raw material analysis? Optimize Energy Systems with Precise Qualification

- What special features make muffle furnaces suitable for certain applications? Discover High-Temperature Precision Solutions

- What is a batch type furnace? Master Precision Heat Treatment for Diverse Materials

- What role does a muffle furnace play in the synthesis of carbon nitride? Master Thermal Polycondensation Control

- Why are high-precision high-temperature box furnaces required for the segmented heat treatment of LTGP materials?

- What is a muffle furnace and how does it relate to laboratory furnaces? Discover Its Key Benefits for Your Lab

- How is a laboratory muffle furnace used in 3D-printed PP-CF cross-linking? Achieve Thermal Stability at 150 °C