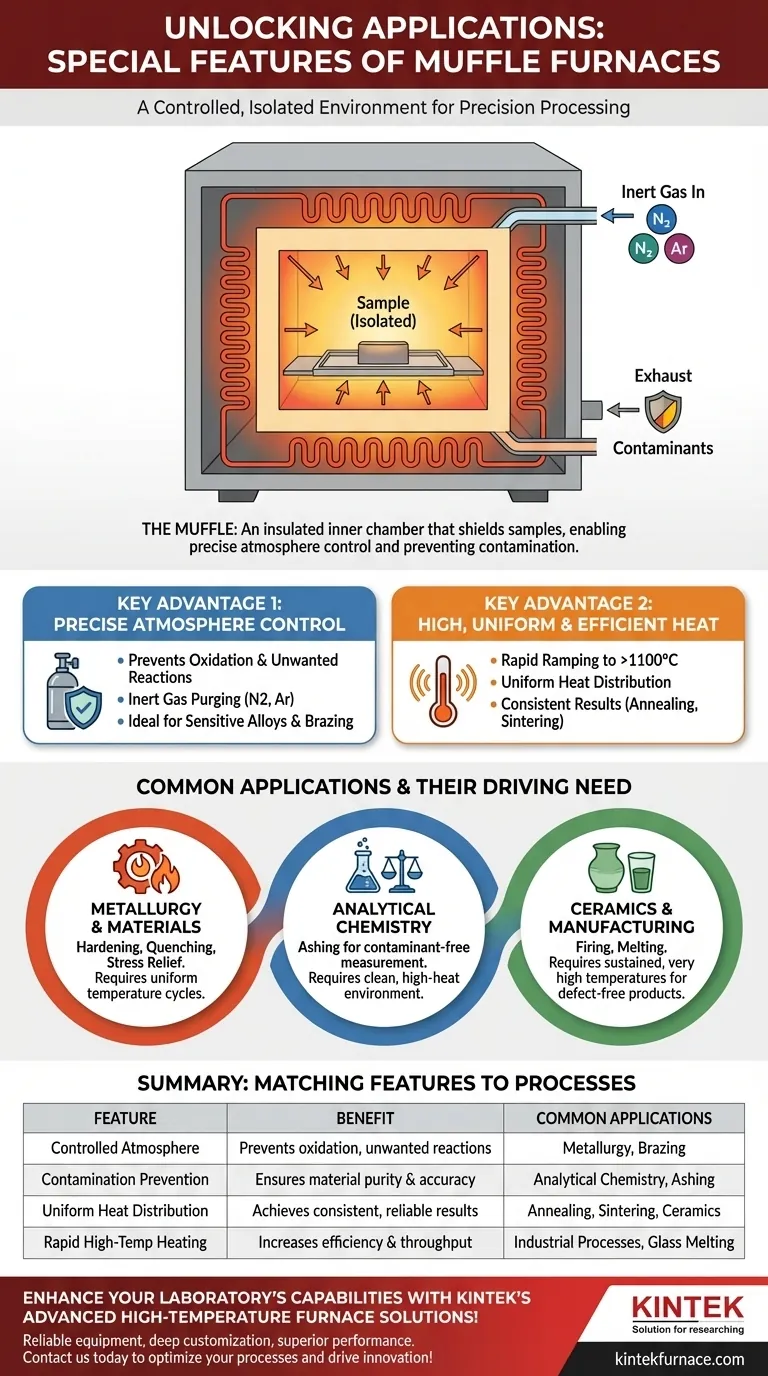

At its core, a muffle furnace excels due to a design that isolates the material being heated from the heat source and outside environment. This separation allows for two critical features: the ability to maintain a controlled atmosphere, preventing unwanted chemical reactions like oxidation, and the prevention of cross-contamination. These capabilities, combined with rapid, high-temperature heating, make muffle furnaces indispensable for sensitive scientific and industrial processes.

A muffle furnace is not just a high-temperature oven; it is a precisely controlled environment. Its primary advantage comes from its "muffle," an inner chamber that shields samples from contamination and allows for atmosphere control, ensuring material integrity during intense heating.

The Defining Feature: The Insulated Muffle Chamber

The name "muffle furnace" comes from its central component: the muffle. Understanding this is key to understanding its capabilities.

What is a Muffle?

A muffle is a sealed, tube-like chamber, typically made of high-temperature ceramic or a metal alloy. This chamber sits inside the furnace, and the heating elements wrap around its exterior.

Your samples or workpieces are placed inside the muffle, meaning they never come into direct contact with the heating elements or any combustion byproducts.

Preventing Direct Contamination

This separation is the furnace's first major advantage. In processes where purity is paramount, direct heating can introduce contaminants from the fuel source or from the degradation of the heating elements themselves.

The muffle acts as a physical barrier, ensuring the only thing touching your material is the controlled atmosphere within the chamber.

Key Advantage 1: Precise Atmosphere Control

Because the muffle is a sealed chamber, you have complete control over the gaseous environment surrounding your sample.

Avoiding Oxidation and Unwanted Reactions

By purging the air and filling the muffle with an inert gas like nitrogen or argon, you create a non-reactive environment. This is critical when working with materials that oxidize (or tarnish) at high temperatures.

This feature makes muffle furnaces ideal for heat-treating sensitive superalloys, refractory metals, and for high-purity brazing and soldering operations where oxides would weaken the final bond.

Suitability for Air and Controlled Atmospheres

While they excel at creating inert atmospheres, muffle furnaces also perform perfectly well with normal air for processes where oxidation is desired or irrelevant, such as ashing samples or firing certain ceramics.

Key Advantage 2: High, Uniform, and Efficient Heat

Muffle furnaces are engineered for demanding thermal applications that require more than just high heat.

Reaching High Temperatures Quickly

Modern muffle furnaces are designed with advanced insulation and powerful heating elements, allowing them to reach extremely high temperatures (often over 1100°C or 2000°F) in a very short time.

This rapid "ramping" ability increases efficiency and throughput in both laboratory and industrial workflows.

Ensuring Uniform Heat Distribution

Because the heating elements surround the muffle, heat radiates inward from all sides. This design promotes a highly uniform temperature zone within the chamber.

Uniform heating is essential for consistent results in processes like annealing (softening metal), tempering (toughening it), and sintering (fusing powders), where uneven temperatures could ruin the workpiece.

Common Applications and Their Driving Need

Different industries leverage these features to solve specific challenges.

Metallurgy and Materials Science

Applications like hardening, quenching, and stress relief rely on the furnace's ability to deliver precise, uniform temperature cycles. The option for an inert atmosphere is critical for developing and processing advanced alloys.

Analytical Chemistry

For chemical analysis, ashing is a common use. The furnace provides a clean, high-heat environment to completely burn away organic matter from a sample, leaving only the inorganic residue (ash) for accurate measurement without fear of contamination.

Ceramics and Manufacturing

The production of technical ceramics, enamel coatings, and melted glass all depend on the furnace's ability to provide sustained, uniform, and very high temperatures to ensure the final products are free of defects.

Making the Right Choice for Your Process

Use this guide to determine if a muffle furnace meets your core requirement.

- If your primary focus is material purity and preventing oxidation: The muffle furnace's ability to maintain a clean, inert atmosphere is its defining and most critical advantage.

- If your primary focus is analytical accuracy, like ashing: The furnace's clean, contaminant-free heating ensures the integrity and accuracy of your results.

- If your primary focus is consistent heat treatment or material processing: The uniform temperature distribution is essential for achieving reliable and repeatable outcomes in processes like annealing, sintering, or ceramics firing.

By understanding how a muffle furnace isolates and controls the heating environment, you can confidently select it for your most sensitive high-temperature applications.

Summary Table:

| Feature | Benefit | Common Applications |

|---|---|---|

| Controlled Atmosphere | Prevents oxidation and unwanted reactions | Metallurgy, Brazing |

| Contamination Prevention | Ensures material purity and accuracy | Analytical Chemistry, Ashing |

| Uniform Heat Distribution | Achieves consistent, reliable results | Annealing, Sintering, Ceramics |

| Rapid High-Temperature Heating | Increases efficiency and throughput | Industrial Processes, Glass Melting |

Enhance your laboratory's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable equipment like Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures precise solutions for your unique experimental needs, delivering superior performance, contamination-free results, and consistent outcomes. Contact us today to discuss how we can optimize your processes and drive innovation in your work!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the purpose of heating a precursor solution to 80 °C and 300 rpm stirring? Achieve High-Entropy Uniformity

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- Why is re-calcination in a muffle furnace necessary for photocatalysts? Restore Efficiency via Thermal Oxidation

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO