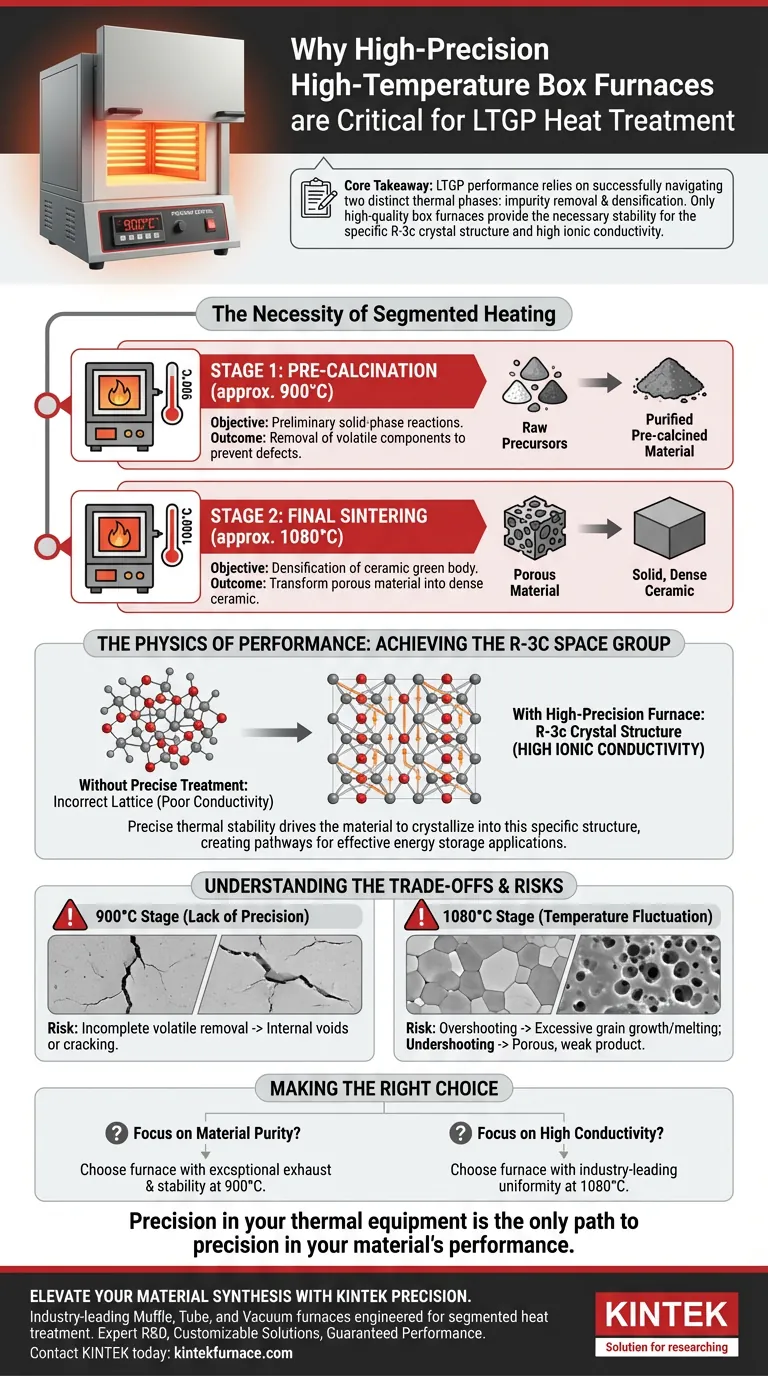

High-precision high-temperature box furnaces are critical for processing LTGP materials because the synthesis requires a strictly controlled, two-stage thermal transformation. These furnaces provide the stability needed to hold the material first at approximately 900°C for pre-calcination, and subsequently at 1080°C for final sintering, ensuring the correct chemical and structural evolution.

Core Takeaway The performance of LTGP relies entirely on successfully navigating two distinct thermal phases: impurity removal and densification. Without the precise temperature regulation of a high-quality box furnace, the material cannot achieve the specific R-3c crystal structure required for high ionic conductivity.

The Necessity of Segmented Heating

The preparation of LTGP (Lithium Titanium Germanium Phosphate) is not a linear heating process. It requires a "segmented" approach where the material is treated at two specific temperature plateaus to achieve distinct physical goals.

Stage 1: Pre-calcination at 900°C

The first critical phase occurs at approximately 900°C.

A high-precision furnace is required here to facilitate preliminary solid-phase reactions.

At this temperature, the furnace ensures the removal of volatile components from the raw precursors. This purification step is essential to prevent defects in the final ceramic structure.

Stage 2: Final Sintering at 1080°C

The second phase demands an increase in temperature to approximately 1080°C.

The primary goal here is the densification of the ceramic green body.

The furnace must maintain this temperature accurately to transform the porous pre-calcined material into a solid, dense ceramic.

The Physics of Performance

The ultimate reason for using high-precision equipment is to dictate the microscopic arrangement of atoms within the material.

Achieving the R-3c Space Group

The thermal stability provided by the box furnace drives the material to crystallize into a specific structure known as the R-3c space group.

If the temperature fluctuates or misses the target, this specific crystal lattice may not form correctly.

Maximizing Ionic Conductivity

The formation of the R-3c structure is directly linked to performance.

This specific crystal arrangement provides the pathways necessary for high ionic conductivity.

Without the precise heat treatment facilitated by the furnace, the final material would lack the conductivity required for effective energy storage applications.

Understanding the Trade-offs

While high-precision box furnaces are the standard for this process, it is important to understand the operational risks associated with thermal processing.

The Risk of Thermal Instability

If the furnace lacks precision during the 900°C stage, incomplete removal of volatiles can lead to internal voids or cracking during the final sintering.

The Sensitivity of Sintering

At the 1080°C stage, "overshooting" the temperature can lead to excessive grain growth or melting, while "undershooting" results in a porous, mechanically weak product with poor conductivity.

Making the Right Choice for Your Goal

To ensure the successful preparation of LTGP materials, align your equipment choice with your specific objective.

- If your primary focus is Material Purity: Prioritize a furnace with exceptional exhaust capabilities and stability at 900°C to ensure complete volatile removal during pre-calcination.

- If your primary focus is High Conductivity: Ensure your furnace has industry-leading temperature uniformity at 1080°C to guarantee the formation of the R-3c crystal phase throughout the entire batch.

Precision in your thermal equipment is the only path to precision in your material's performance.

Summary Table:

| Heating Stage | Temperature | Primary Objective | Critical Outcome |

|---|---|---|---|

| Pre-calcination | 900°C | Volatile removal & preliminary reaction | Material purity & defect prevention |

| Final Sintering | 1080°C | Ceramic densification | R-3c crystal structure formation |

| Result | N/A | High ionic conductivity | Optimized energy storage performance |

Elevate Your Material Synthesis with KINTEK Precision

Don't let thermal fluctuations compromise your LTGP research. KINTEK provides industry-leading Muffle, Tube, and Vacuum furnaces engineered for the rigorous demands of segmented heat treatment. Our systems offer the temperature uniformity and stability required to achieve the perfect R-3c crystal structure for high-performance energy storage.

Why choose KINTEK?

- Expert R&D & Manufacturing: Precision-built for lab and industrial standards.

- Customizable Solutions: Tailored configurations for CVD, rotary, or high-temp needs.

- Guaranteed Performance: Optimized for impurity removal and dense ceramic sintering.

Ready to achieve superior ionic conductivity? Contact KINTEK today for a custom furnace solution!

Visual Guide

References

- Benjamin X. Lam, Gerbrand Ceder. Degradation Mechanism of Phosphate‐Based Li‐NASICON Conductors in Alkaline Environment. DOI: 10.1002/aenm.202403596

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- How does a muffle furnace differ from a regular oven or furnace? Discover Precision Heating Solutions

- What materials are used in muffle furnace construction? Key Materials for High-Temp Performance

- How does the furnace atmosphere contribute to the function of a muffle furnace? Unlock Precision in Material Processing

- How does high-temperature calcination in a muffle furnace transform precipitates? Expert Insights into Oxide Synthesis

- What are the key differences between a muffle furnace and a vacuum furnace? Choose the Right Furnace for Your Lab

- What factors should be considered when choosing a muffle furnace? Select the Perfect Fit for Your Lab

- What is the function of a box-type resistance furnace in GFRP studies? Mastering High-Temperature Material Simulation

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization