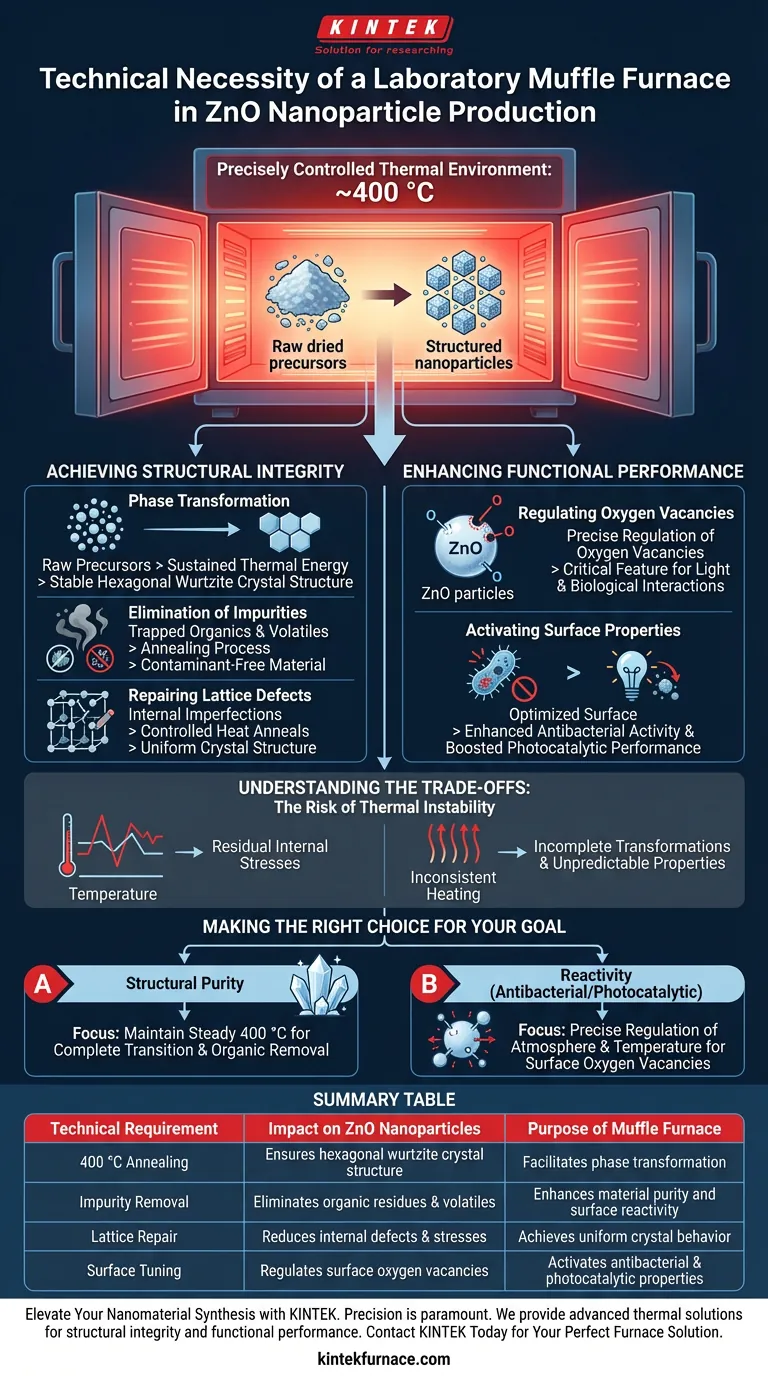

The technical necessity of a laboratory muffle furnace lies in its ability to provide a precisely controlled thermal environment—specifically around 400 °C—which is required to synthesize functional Zinc Oxide (ZnO) nanoparticles. This apparatus ensures the complete phase transformation of dried precursors into a stable hexagonal wurtzite crystal structure. Without this specific high-temperature annealing, the material would retain internal lattice defects and organic residues, rendering it ineffective for advanced applications.

The muffle furnace does more than simply dry the material; it acts as a structural regulator. By maintaining a stable 400 °C environment, it optimizes surface oxygen vacancies, which is the precise mechanism required to activate the ZnO nanoparticles' antibacterial and photocatalytic capabilities.

Achieving Structural Integrity

The primary role of the muffle furnace is to facilitate the crystallization process that turns raw chemical precursors into a usable semiconductor material.

Phase Transformation

Raw zinc precursors do not naturally possess the crystalline structure required for high performance.

The muffle furnace provides the sustained thermal energy needed to force a phase transition.

This converts the precursors into a thermodynamically stable hexagonal wurtzite crystal structure, which defines the physical properties of the final Zinc Oxide product.

Elimination of Impurities

During the initial synthesis stages, organic matter and volatiles are often trapped within the material.

The annealing process efficiently burns off these residual organics.

This purification prevents contaminants from interfering with the material's surface reactivity.

Repairing Lattice Defects

Synthesizing nanoparticles often introduces imperfections within the crystal lattice.

The controlled heat of the muffle furnace anneals these internal lattice defects.

This results in a more uniform crystal structure, which is essential for consistent material behavior.

Enhancing Functional Performance

Beyond basic structure, the muffle furnace is the tool used to "tune" the chemical behavior of the nanoparticle surface.

Regulating Oxygen Vacancies

For Zinc Oxide, performance is often dictated by the presence and arrangement of oxygen vacancies.

The muffle furnace allows for the precise regulation of these surface oxygen vacancies.

This regulation is not a defect to be removed, but a critical feature that dictates how the particle interacts with light and biological environments.

Activating Surface Properties

The specific arrangement of the crystal surface directly impacts its utility.

Properly annealed ZnO nanoparticles exhibit enhanced antibacterial activity.

Furthermore, this thermal treatment significantly boosts photocatalytic performance, allowing the particles to break down pollutants or react under light exposure effectively.

Understanding the Trade-offs

While the muffle furnace is essential, the process relies heavily on the precision of the parameters used.

The Risk of Thermal Instability

The benefit of the furnace is entirely dependent on its ability to maintain a stable thermal field.

Fluctuations in temperature or cooling curves can induce new residual internal stresses rather than relieving them.

Inconsistent heating can lead to incomplete phase transformations, resulting in a product with unpredictable electronic or optical properties.

Making the Right Choice for Your Goal

The parameters you set on your muffle furnace should be dictated by the specific properties you need to isolate in the Zinc Oxide.

- If your primary focus is Structural Purity: Ensure the furnace maintains a steady 400 °C to guarantee a complete transition to the hexagonal wurtzite structure and the total removal of organic matter.

- If your primary focus is Reactivity (Antibacterial/Photocatalytic): Prioritize the precise regulation of the annealing atmosphere and temperature to optimize the density of surface oxygen vacancies.

Success in ZnO production is not just about reaching high temperatures, but about utilizing the muffle furnace to architect the atomic structure of the material.

Summary Table:

| Technical Requirement | Impact on ZnO Nanoparticles | Purpose of Muffle Furnace |

|---|---|---|

| 400 °C Annealing | Ensures hexagonal wurtzite crystal structure | Facilitates phase transformation |

| Impurity Removal | Eliminates organic residues & volatiles | Enhances material purity and surface reactivity |

| Lattice Repair | Reduces internal defects and stresses | Achieves uniform crystal behavior |

| Surface Tuning | Regulates surface oxygen vacancies | Activates antibacterial & photocatalytic properties |

Elevate Your Nanomaterial Synthesis with KINTEK

Precision is paramount when synthesizing ZnO nanoparticles. KINTEK provides the advanced thermal solutions necessary to ensure structural integrity and functional performance in your lab. Backed by expert R&D and manufacturing, we offer high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems, all fully customizable to meet your specific annealing requirements.

Ready to optimize your high-temperature processes? Contact KINTEK Today to Find Your Perfect Furnace Solution

Visual Guide

References

- Nives Matijaković Mlinarić, Klemen Bohinc. Poly(Allylamine Hydrochloride) and ZnO Nanohybrid Coating for the Development of Hydrophobic, Antibacterial, and Biocompatible Textiles. DOI: 10.3390/nano14070570

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the applications of muffle furnaces? Essential for High-Temperature Material Processing

- What is the function of a forced convection oven during the preparation of TiH2 powder from TiO2? Ensure Purity Now

- What is the primary function of a laboratory oven during the initial processing of geopolymer samples? Expert Guide

- What core function does a muffle furnace serve in superconducting material synthesis? Master Solid-State Reactions

- Why is a Muffle Furnace required for lithium recovery? Boost Yield with Precise Sulfuric Acid Roasting

- What is the difference between a retort and a muffle furnace? Choose the Right Atmosphere-Controlled Furnace

- How is a high-temperature muffle furnace utilized to evaluate the oxidation resistance of Cr2AlC ceramics?

- How does an industrial-grade muffle furnace contribute to the catalyst activation process? Maximize Catalyst Efficiency