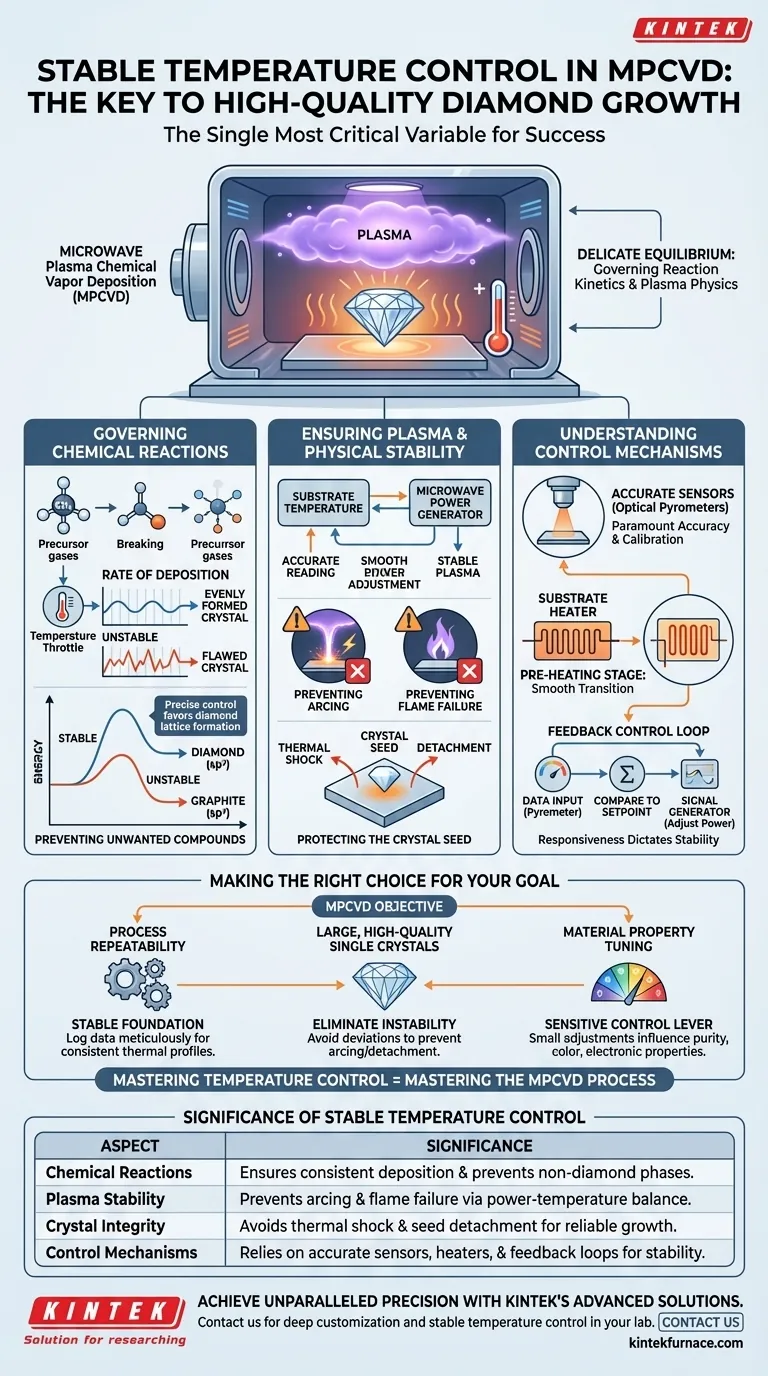

At its core, stable temperature control in Microwave Plasma Chemical Vapor Deposition (MPCVD) is the single most critical variable for successfully growing high-quality diamond. Without it, the process becomes unpredictable and unreliable. Precise temperature management ensures the chemical reactions proceed correctly, the plasma remains stable, and the growing crystal is not physically damaged, directly determining the quality and viability of the final product.

The challenge of MPCVD is maintaining a delicate equilibrium. Stable temperature control is not just about heat; it's the primary mechanism for governing the reaction kinetics and plasma physics that allow carbon atoms to arrange into a diamond lattice instead of worthless soot or a flawed crystal.

The Foundation: Governing Chemical Reactions

The entire CVD process is built on temperature-dependent chemical reactions. Even minor fluctuations can have a cascading effect on the outcome.

The Rate of Deposition

Temperature acts as the throttle for the chemical reactions that break down precursor gases (like methane) and deposit carbon onto the substrate.

An unstable temperature leads to an erratic deposition rate. This results in an unevenly formed crystal with inconsistent properties and internal stress.

Preventing Unwanted Compounds

The energy difference between forming diamond (sp3-hybridized carbon) and graphite (sp2-hybridized carbon) is small.

Precise temperature control ensures the reaction environment favors the formation of the diamond lattice. Deviations can easily lead to the growth of non-diamond carbon phases, which are considered defects.

Ensuring Plasma and Physical Stability

Temperature is inextricably linked to the stability of the microwave plasma itself. Instability in one creates instability in the other, often leading to catastrophic process failure.

The Link to Microwave Power

The temperature of the substrate is maintained through a feedback loop with the microwave power generator. The system constantly measures the temperature and adjusts the power to keep it at the setpoint.

Smooth, continuous power adjustment is only possible with an accurate and stable temperature reading. This prevents sudden power spikes or drops that disrupt the plasma.

Preventing Arcing and Flame Failure

An unstable plasma can lead to arcing, where the plasma discharge concentrates into a small, intensely hot arc. This can severely damage the substrate and the growing diamond.

Alternatively, instability can cause a "flame failure," where the plasma extinguishes entirely, halting the growth process. Both are often rooted in the system's inability to maintain a stable power-temperature balance.

Protecting the Crystal Seed

Successful MPCVD requires a diamond "seed" crystal to be placed on a substrate. The new diamond grows on top of this seed.

Sudden temperature changes or plasma arcing can create thermal shock or physical force strong enough to detach the seed crystal from the substrate, resulting in a complete failure of the growth run.

Understanding Key Control Mechanisms

Achieving the necessary stability requires a sophisticated control system where several components work in concert. Mismanagement of any single component undermines the entire process.

The Importance of Accurate Sensors

Temperature is typically measured by non-contact optical pyrometers. The accuracy and calibration of these sensors are paramount.

An inaccurate temperature reading means the entire control system is working with bad data, making true stability impossible regardless of how well the other components function.

The Substrate Heater

Before the plasma is even ignited, a resistive heater within the substrate holder brings the system to a baseline temperature.

This pre-heating stage ensures a smooth and controlled transition when the microwave plasma is introduced, preventing thermal shock to the components.

The Feedback Control Loop

The core of the system is the software-driven feedback loop. It reads the pyrometer data, compares it to the desired setpoint, and sends a signal to the microwave generator to increase or decrease power.

The responsiveness and intelligence of this control loop dictate how effectively the system can reject disturbances and maintain a truly stable temperature.

Making the Right Choice for Your Goal

Your specific objective in using MPCVD will determine how you prioritize and monitor temperature stability.

- If your primary focus is process repeatability: Stable temperature is your foundation. Log temperature data meticulously to ensure every run follows the exact same thermal profile.

- If your primary focus is growing large, high-quality single crystals: You must eliminate all sources of instability. Any deviation risks arcing or seed detachment, which are catastrophic failures for long, expensive growth runs.

- If your primary focus is material property tuning: Temperature is your most sensitive control lever. Small, deliberate adjustments in your stable temperature setpoint are how you will influence the final diamond's purity, color, and electronic properties.

Mastering temperature control is equivalent to mastering the MPCVD process itself.

Summary Table:

| Aspect | Significance |

|---|---|

| Chemical Reactions | Ensures consistent deposition rate and prevents non-diamond carbon phases |

| Plasma Stability | Prevents arcing and flame failure by maintaining power-temperature balance |

| Crystal Integrity | Avoids thermal shock and seed detachment for reliable growth |

| Control Mechanisms | Relies on accurate sensors, substrate heaters, and feedback loops for stability |

Achieve unparalleled precision in your MPCVD processes with KINTEK's advanced solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with high-temperature furnace systems like CVD/PECVD, tailored to your unique experimental needs. Our deep customization capabilities ensure stable temperature control for growing high-quality diamonds and other materials. Contact us today to discuss how we can enhance your lab's efficiency and results!

Visual Guide

Related Products

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- HFCVD Machine System Equipment for Drawing Die Nano Diamond Coating

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

People Also Ask

- What are 2D heterostructures and how are they created using CVD tube furnaces? Unlock Atomic-Scale Material Engineering

- What are the key features of CVD tube furnaces for 2D material processing? Unlock Precision Synthesis for Superior Materials

- What future trends are expected in the development of CVD tube furnaces? Discover Smarter, More Versatile Systems

- What are the advantages of CVD tube furnace sintering systems? Achieve Superior Material Control and Purity

- What are the practical applications of gate media prepared by CVD tube furnaces? Unlock Advanced Electronics and More