At its core, routine inspection of a dental furnace is a critical preventative measure designed to identify potential issues before they cause catastrophic failure. A proper inspection protocol prolongs the equipment's lifespan by systematically checking the integrity of core components like electrical connections, heating elements, and ventilation systems.

Routine furnace inspections are not merely about preventing breakdowns. They are a fundamental quality control process that directly impacts the consistency of restorations, the safety of your practice, and the long-term financial health of your operations.

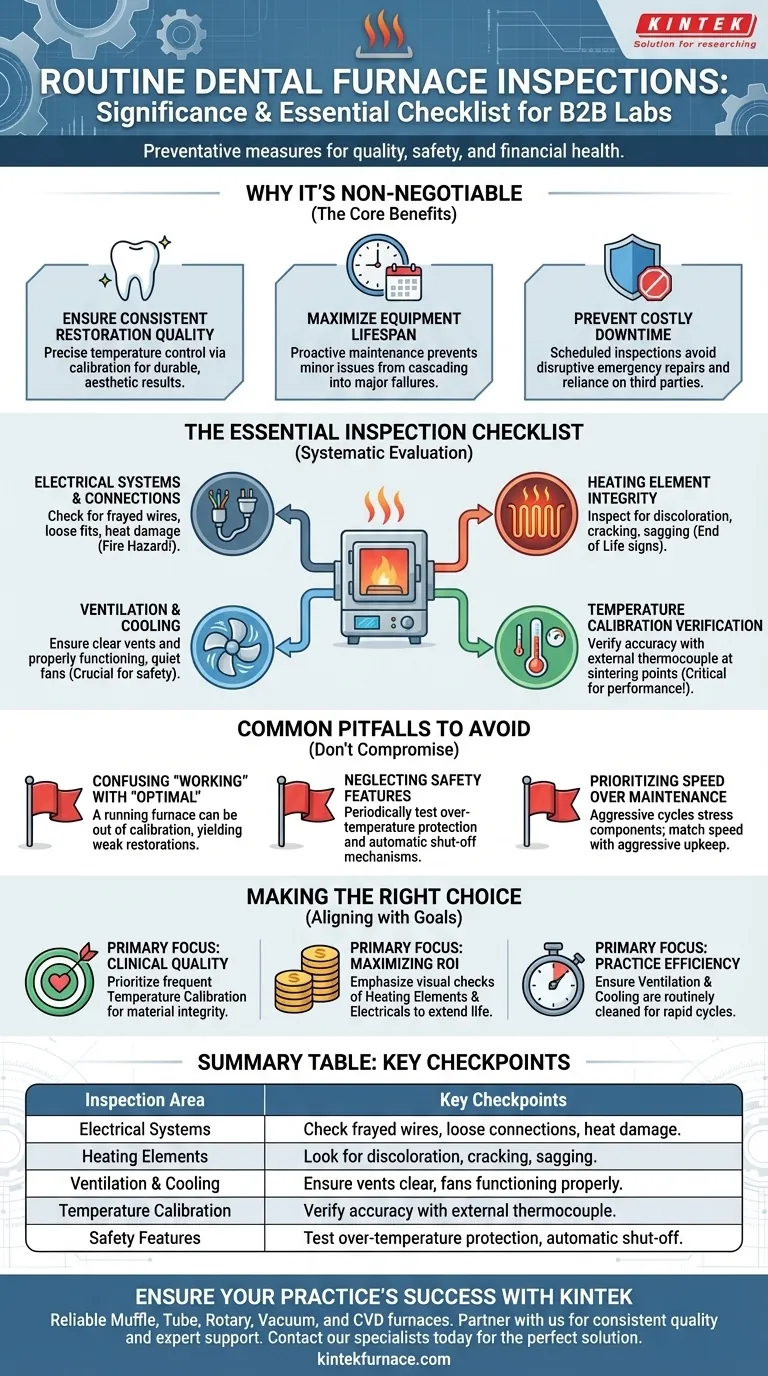

Why Routine Inspections Are Non-Negotiable

A furnace that simply turns on is not necessarily one that is performing correctly. Understanding the deeper implications of regular maintenance reveals its true value beyond simple operational checks.

Ensuring Consistent Restoration Quality

The ultimate goal of a dental furnace is to produce strong, durable, and aesthetic ceramic restorations. This requires precise temperature control.

Regular inspections, especially temperature calibration verification, ensure the furnace reaches and maintains the exact temperatures required for specific materials. An uncalibrated furnace can compromise the final product's strength and adhesion.

Maximizing Equipment Lifespan

A dental furnace is a significant capital investment. Proactive maintenance is the most effective strategy to protect that investment.

Identifying and addressing minor issues, such as a frayed wire or a struggling cooling fan, prevents them from cascading into major, costly component failures.

Preventing Costly Downtime

An unexpected furnace breakdown brings in-house production to a halt. This forces a sudden and expensive reliance on third-party labs, leading to delays and loss of control over the final product.

Scheduled inspections catch problems on your terms, allowing for planned maintenance instead of disruptive emergency repairs.

The Essential Inspection Checklist

A comprehensive inspection moves beyond a simple visual check. It should be a systematic evaluation of the systems that dictate performance and safety.

Electrical Systems and Connections

All power cords and internal connections should be checked for a secure fit and any signs of wear, fraying, or heat damage. Loose connections are a common point of failure and a potential fire hazard.

Heating Element Integrity

The heating elements are the heart of the furnace. A visual inspection should look for any signs of discoloration, cracking, or sagging, which indicate they are nearing the end of their service life.

Ventilation and Cooling Systems

Proper airflow is crucial for both efficient cycle times and operational safety. Ensure all vents are clear of obstructions and that cooling fans are functioning without unusual noise or vibration.

Temperature Calibration Verification

This is the most critical performance check. Using a calibrated external thermocouple, verify that the furnace's displayed temperature matches the actual internal temperature at key sintering points. This directly confirms the furnace's accuracy.

Common Pitfalls to Avoid

Simply going through the motions of an inspection is not enough. To be effective, you must avoid common assumptions and oversights that can undermine the process.

Confusing "Working" with "Optimal"

A furnace can power on and complete a cycle while being significantly out of calibration. This deviation can produce restorations that look acceptable but lack the required strength, leading to premature clinical failure.

Neglecting Safety Features

Modern furnaces include safety mechanisms like over-temperature protection and automatic shut-off. These systems must be tested periodically to ensure they will function correctly in an emergency. Never assume they are working without verification.

Prioritizing Speed Over Maintenance

Pushing for the fastest possible cycle times places significant stress on the furnace's components, particularly the heating elements and cooling system. An aggressive production schedule must be matched with an equally aggressive maintenance schedule to prevent premature failure.

Making the Right Choice for Your Goal

Your maintenance protocol should align with your practice's primary objectives.

- If your primary focus is consistent clinical quality: Prioritize frequent temperature calibration as the most critical inspection point to guarantee material integrity.

- If your primary focus is maximizing ROI: Emphasize regular visual checks of heating elements and electricals to prevent expensive emergency repairs and extend the furnace's usable life.

- If your primary focus is practice efficiency: Ensure ventilation and cooling systems are routinely inspected and cleaned to maintain rapid and reliable cycle times.

Ultimately, treating your dental furnace as a precision instrument that requires regular care is the key to unlocking its full potential for your practice.

Summary Table:

| Inspection Area | Key Checkpoints |

|---|---|

| Electrical Systems | Check for frayed wires, loose connections, and heat damage. |

| Heating Elements | Look for discoloration, cracking, or sagging. |

| Ventilation & Cooling | Ensure vents are clear and fans are functioning properly. |

| Temperature Calibration | Verify accuracy with an external thermocouple. |

| Safety Features | Test over-temperature protection and automatic shut-off. |

Ensure your practice's success with a reliable furnace from KINTEK.

Your dental furnace is the cornerstone of your in-house lab, directly impacting restoration quality and practice efficiency. Backed by expert R&D and manufacturing, KINTEK offers Muffle, Tube, Rotary, Vacuum, and CVD furnaces, all customizable for your unique needs.

Don't let unexpected downtime compromise your workflow. Our precision equipment and expert support help you maintain consistent quality and maximize your investment.

Contact our specialists today to find the perfect furnace solution for your practice.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What factors determine the quality of sintered zirconia restorations? Master Material, Equipment, and Technique

- What are the effects of overloading a dental sintering furnace? Ensure Predictable, High-Quality Zirconia Restorations

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What is a dental sintering furnace and what is its purpose? Achieve High-Strength Dental Restorations