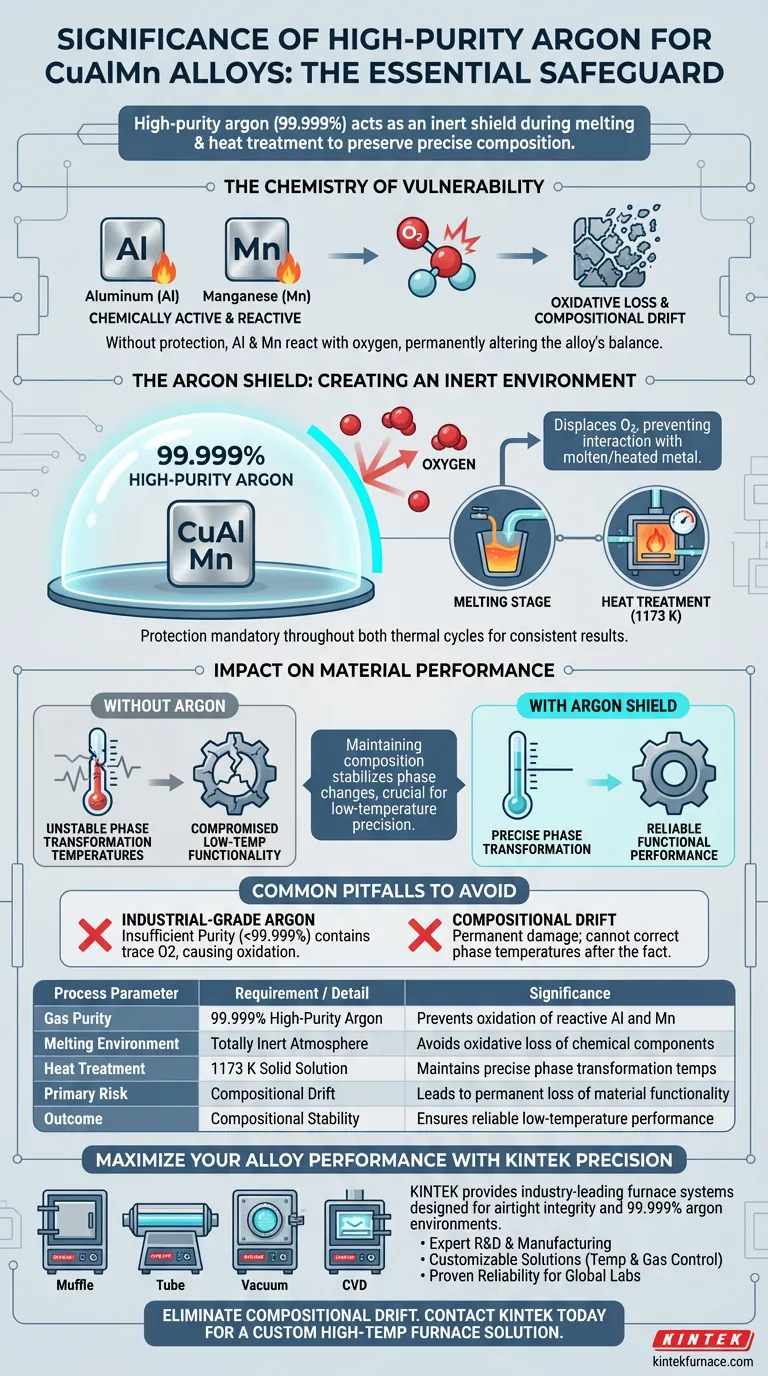

High-purity argon serves as an essential chemical safeguard. It acts as an inert shield during the high-temperature melting and heat treatment of Copper-Aluminum-Manganese (CuAlMn) alloys to preserve the material's precise composition. By isolating the alloy from oxygen, argon prevents the degradation of reactive elements and ensures the material functions correctly.

The Core Insight Because Aluminum and Manganese are highly reactive, a 99.999% pure argon atmosphere is required to prevent oxidation. Without this protection, the loss of these elements alters the alloy's chemical balance, causing critical shifts in phase transformation temperatures and compromising performance at low temperatures.

The Chemistry of Vulnerability

The Reactivity of Aluminum and Manganese

CuAlMn alloys rely heavily on the presence of Aluminum and Manganese. However, both of these elements are chemically active.

They are prone to rapid oxidation when exposed to oxygen. This vulnerability is significantly heightened during high-temperature processes.

The Risk of Oxidative Loss

If oxygen contacts the alloy during heating, the Aluminum and Manganese will react and burn off. This results in the oxidative loss of components.

This loss is not just a surface defect; it fundamentally changes the ratio of elements within the bulk material.

The Role of the Argon Shield

Creating an Inert Environment

To counter oxidation, the process requires an atmosphere of high-purity argon (99.999%).

This gas creates a completely inert environment. It effectively displaces oxygen, preventing it from interacting with the molten or heated metal.

Critical Processing Stages

This protection is necessary at two distinct stages: during the initial melting and during the 1173 K solid solution treatment.

Maintaining the protective atmosphere throughout these specific thermal cycles is mandatory for consistent results.

Impact on Material Performance

Stabilizing Phase Transformation

The primary reason for preventing element loss is to stabilize phase transformation temperatures.

The specific temperatures at which the alloy changes phase are dictated by its chemical composition. If Al or Mn levels drop due to oxidation, these transformation points will shift unpredictably.

Ensuring Low-Temperature Functionality

By preventing compositional shifts, the argon shield guarantees the alloy behaves as intended.

This strict control is the only way to ensure the functional performance of the alloy, particularly in low-temperature applications where precision is paramount.

Common Pitfalls to Avoid

The Danger of Insufficient Purity

Using standard industrial-grade argon is often a mistake in this context.

The reference specifically calls for 99.999% purity. Lower purity grades may contain trace amounts of oxygen sufficient to induce oxidation in these highly reactive elements.

The Cost of Compositional Drift

Ignoring the protective atmosphere leads to "compositional drift."

You cannot correct the phase transformation temperatures after the fact if the elements have already oxidized. The damage to the alloy's functional properties is permanent.

Making the Right Choice for Your Goal

To ensure your CuAlMn alloy performs reliably, apply the following principles:

- If your primary focus is Compositional Accuracy: Ensure your argon supply is certified to 99.999% purity to prevent the oxidative loss of active Aluminum and Manganese.

- If your primary focus is Thermal Reliability: Maintain this inert atmosphere strictly during the 1173 K solid solution treatment to prevent shifts in phase transformation temperatures.

Strict atmospheric control is not an optional step; it is the prerequisite for predictable alloy performance.

Summary Table:

| Process Parameter | Requirement / Detail | Significance |

|---|---|---|

| Gas Purity | 99.999% High-Purity Argon | Prevents oxidation of reactive Al and Mn |

| Melting Environment | Totally Inert Atmosphere | Avoids oxidative loss of chemical components |

| Heat Treatment | 1173 K Solid Solution | Maintains precise phase transformation temps |

| Primary Risk | Compositional Drift | Leads to permanent loss of material functionality |

| Outcome | Compositional Stability | Ensures reliable low-temperature performance |

Maximize Your Alloy Performance with KINTEK Precision

Don't let oxidative loss compromise your material research or production. KINTEK provides industry-leading Muffle, Tube, Vacuum, and CVD furnace systems designed specifically to maintain the ultra-pure atmospheric conditions required for sensitive processes like CuAlMn heat treatment.

Why choose KINTEK?

- Expert R&D & Manufacturing: Our systems ensure airtight integrity for 99.999% argon environments.

- Customizable Solutions: Tailor temperature profiles and gas control to your unique alloy needs.

- Proven Reliability: Trusted by global laboratories for stabilizing phase transformation and functional performance.

Ready to eliminate compositional drift? Contact KINTEK today for a custom high-temp furnace solution!

Visual Guide

References

- Adelaide Nespoli, Carlo Fanciulli. A Study of a Cryogenic CuAlMn Shape Memory Alloy. DOI: 10.3390/met14030323

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Magnesium Extraction and Purification Condensing Tube Furnace

People Also Ask

- What are the operational considerations for atmosphere furnaces? Master Precise Control for Safe, Efficient Results

- What function does a flow-gas furnace serve in iron ore reduction? Mastering Lab Gas Delivery and Thermal Sync

- What is a box type annealing atmosphere furnace? Master Controlled Heat Treatment for Superior Materials

- What are the primary functions of industrial-grade constant temperature furnaces for NiCoCrAlY oxidation kinetics?

- Why are high-temperature annealing furnaces and H2-N2 atmospheres required for oriented silicon steel research?

- What effects does a reducing atmosphere have on ceramic wares during firing? Unlock Deep Colors and Unique Finishes

- What high-temperature processes commonly use argon in furnaces? Essential Guide for Reactive Metals

- Why is a cylindrical atmosphere furnace utilized for the salt removal process in porous stainless steel fabrication?