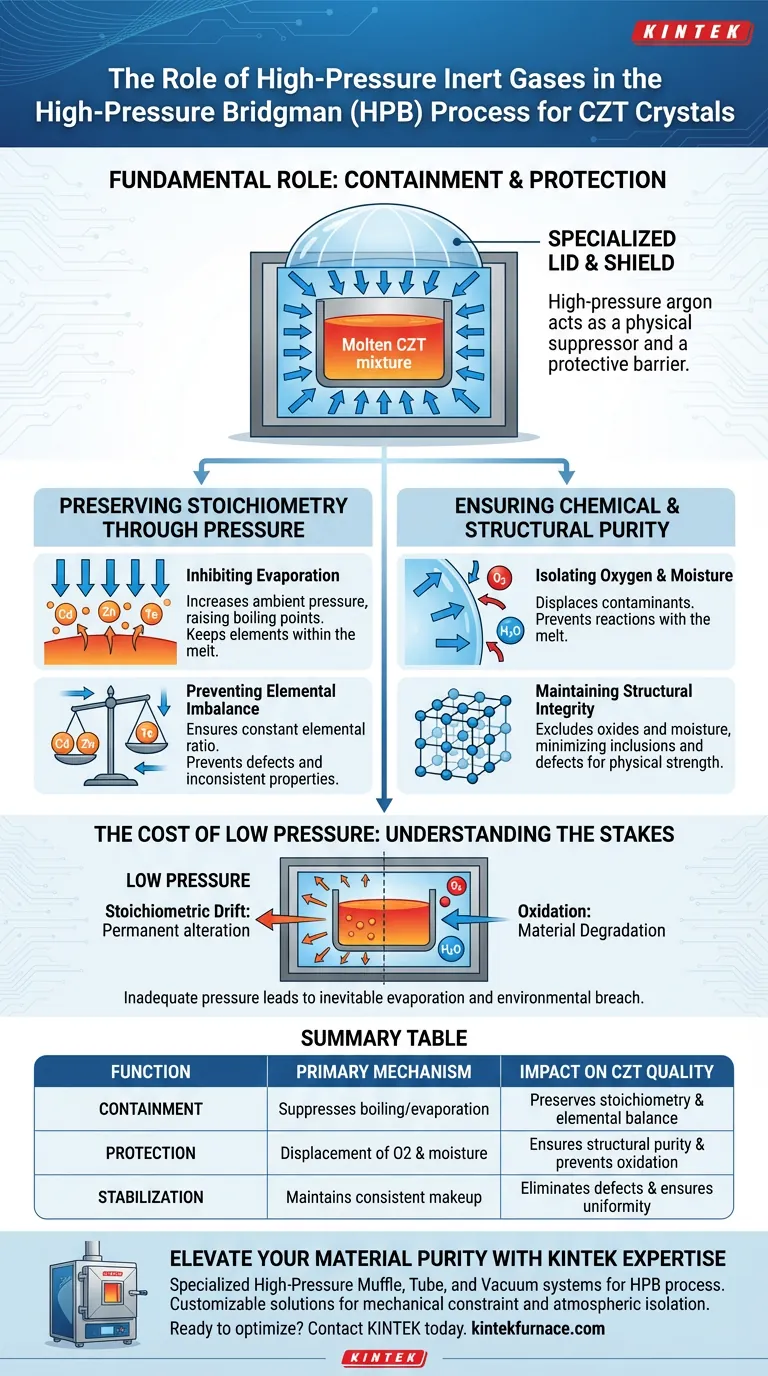

The role of high-pressure inert gases is fundamentally one of containment and protection. In the High-Pressure Bridgman (HPB) process, gases like argon act as a physical suppressor to stop volatile elements from escaping the molten Cadmium Zinc Telluride (CZT) mixture while simultaneously shielding the material from atmospheric contamination.

Core Takeaway The introduction of high-pressure argon is not merely for atmosphere control; it is a critical mechanical constraint. It actively prevents the evaporation of volatile components to maintain the correct elemental ratio (stoichiometry) and creates a barrier against oxygen and moisture to ensure structural purity.

Preserving Stoichiometry Through Pressure

Inhibiting Component Evaporation

When CZT is in a molten state, its constituent elements are highly volatile and prone to evaporation. High-pressure argon serves to inhibit this evaporation.

By increasing the ambient pressure within the furnace, you raise the boiling point of the volatile components. This physical pressure keeps the elements within the melt rather than allowing them to transition into a gas phase and escape.

Preventing Elemental Imbalance

The primary risk during crystal growth is a shift in the chemical makeup of the material. If components evaporate at different rates, the resulting crystal will suffer from an imbalance in elemental proportions.

This imbalance leads to defects and inconsistent electrical properties. The high-pressure gas ensures that the ratio of Cadmium, Zinc, and Tellurium remains constant throughout the growth cycle.

Ensuring Chemical and Structural Purity

Isolating Oxygen and Moisture

Beyond managing volatility, the HPB process utilizes the pressurized environment to effectively isolate the melt from external contaminants.

Oxygen and moisture are particularly detrimental to semiconductor crystals. The high-pressure argon environment displaces these contaminants, preventing them from reacting with the molten material.

Maintaining Structural Integrity

Chemical purity is directly linked to the physical strength and order of the crystal. By excluding oxides and moisture, the process ensures the structural integrity of the final crystal.

A chemically pure growth environment minimizes the formation of inclusions or structural defects that would otherwise compromise the crystal's performance.

Understanding the Stakes: The Cost of Low Pressure

The Consequence of Inadequate Pressure

It is critical to understand that this pressure is not optional for high-quality CZT. Without sufficient pressure from the inert gas, evaporation becomes inevitable.

This results in a phenomenon known as "stoichiometric drift." Once the elemental proportions drift, the crystal cannot be recovered; the material properties are permanently altered.

The Risk of Environmental Breach

The high-pressure environment also acts as a rigorous seal. If the pressure is not maintained, or if the isolation is compromised, oxygen ingress will degrade the material immediately.

This leads to oxidation defects that ruin the homogeneity of the crystal lattice.

Making the Right Choice for Your Goal

To maximize the quality of CZT crystals using the HPB process, focus on these operational priorities:

- If your primary focus is Electrical Consistency: Ensure the pressure is high enough to completely inhibit evaporation, as this preserves the precise elemental proportions required for uniform performance.

- If your primary focus is Structural Perfection: Prioritize the integrity of the gas isolation system to rigorously exclude oxygen and moisture, which are the main drivers of structural defects.

Ultimately, the high-pressure gas acts as a vital specialized lid, locking in the chemistry and locking out the contaminants.

Summary Table:

| Function | Primary Mechanism | Impact on CZT Quality |

|---|---|---|

| Containment | High-pressure suppresses boiling/evaporation | Preserves stoichiometry and elemental balance |

| Protection | Displacement of ambient oxygen and moisture | Ensures structural purity and prevents oxidation |

| Stabilization | Maintains consistent chemical makeup | Eliminates defects and ensures electrical uniformity |

Elevate Your Material Purity with KINTEK Expertise

Precise control over high-pressure environments is non-negotiable for high-quality CZT production. Backed by expert R&D and manufacturing, KINTEK offers specialized High-Pressure Muffle, Tube, and Vacuum systems designed to meet the rigorous demands of the HPB process. Whether you require standard equipment or a fully customizable high-temp furnace for your unique research needs, our solutions provide the mechanical constraint and atmospheric isolation necessary for structural perfection.

Ready to optimize your crystal growth? Contact KINTEK today to discuss your custom furnace requirements!

Visual Guide

References

- Z. J. Li, Zeqian Wu. Research on the Technological Progress of CZT Array Detectors. DOI: 10.3390/s24030725

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vertical Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- How does Plasma Flash Sintering (PFS) equipment enable the stabilization of metastable phases? Defy Thermal Limits

- Why are specific heating pulses applied when monitoring molten metal surface oscillations? Unlock Material Insights

- What are some drawbacks of electric heating methods? High Costs and Grid Dependence Explained

- What role does an industrial fast firing furnace play in the metallization of PERT solar cells? Boost Cell Efficiency

- Why are advanced materials and composites important? Unlock Next-Gen Performance in Aerospace, Auto, and More

- What is the catalytic mechanism of methane gas conversion in Ni-Co CNT synthesis? Master Carbon Transformation

- How does a high-precision laboratory oven ensure the performance of large-scale halide perovskite catalyst plates?

- How does precise heating rate control affect nitrogen-doped carbon synthesis? Master Thermal Ramp for Quality Materials