At its core, the primary drawbacks of electric heating are its high operational cost compared to fossil fuels and its complete dependence on the electrical grid. While specific methods like indirect resistance and induction heating are reliable and safe at the point of use, they are not immune to these fundamental economic and infrastructural challenges.

The central trade-off of electric heating is clear: you gain simplicity, installation flexibility, and on-site safety in exchange for potentially higher energy bills and vulnerability to power outages. The true cost and environmental impact are not at the heater itself, but further upstream at the power plant and on your utility bill.

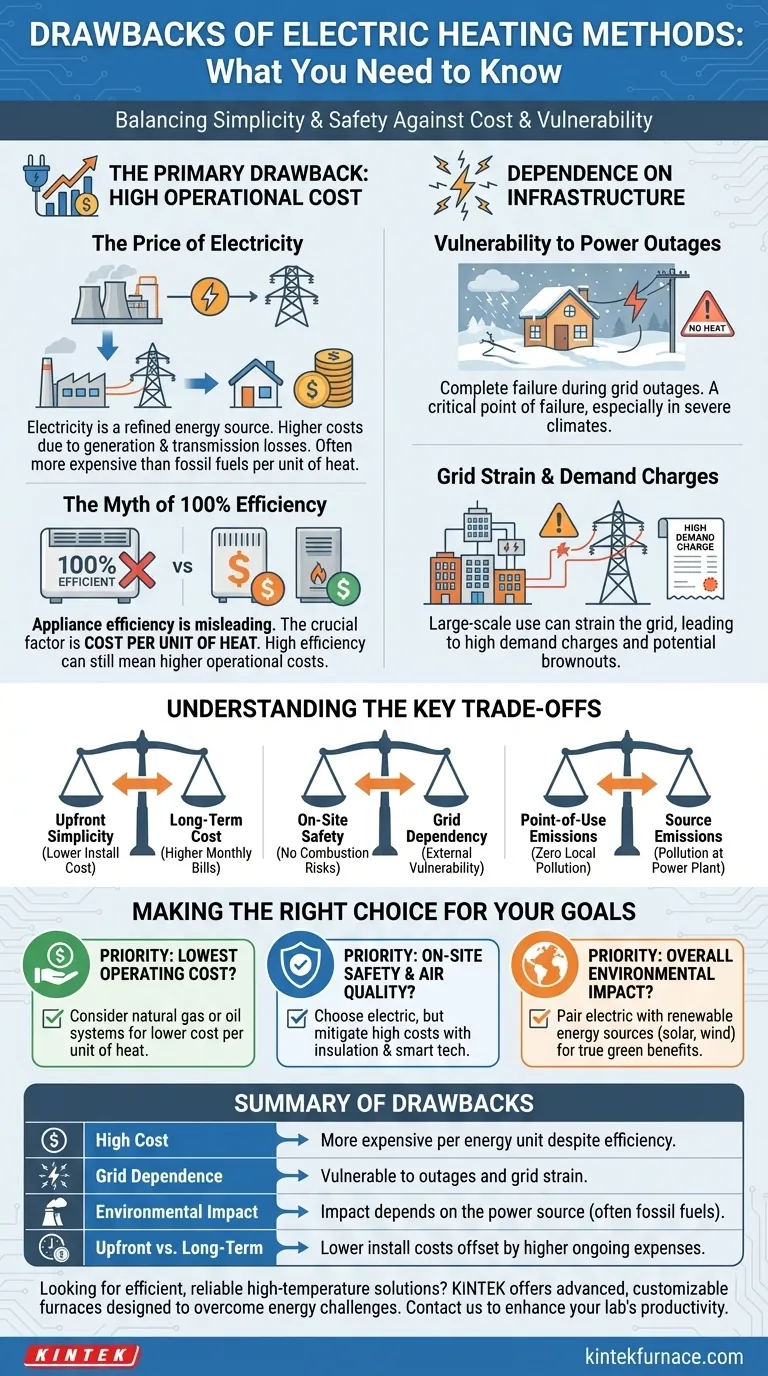

The Primary Drawback: Operational Cost

For most users, the most significant and consistent drawback of electric heating is the long-term cost of operation. This is not an issue of efficiency but one of fundamental energy economics.

The Price of Electricity

Electricity is a refined energy source. The process of generating it (whether from coal, natural gas, nuclear, or renewables) and transmitting it over long distances involves inherent energy losses and infrastructure costs.

As a result, the price per unit of energy (measured in kWh or BTUs) for electricity is often significantly higher than for primary fuels like natural gas or heating oil.

The Myth of 100% Efficiency

Electric resistance heaters are often marketed as "100% efficient" because they convert nearly all incoming electrical energy directly into heat. While technically true at the appliance level, this claim is misleading.

The crucial factor is not the conversion efficiency but the cost per unit of heat produced. A 100% efficient electric heater can easily be more expensive to run than an 85% efficient gas furnace if the price of electricity is substantially higher than the price of gas.

Dependence on Infrastructure

Electric heating systems are entirely reliant on a stable and robust electrical grid. This introduces risks that are not present with fuel-based systems that can store energy on-site (like propane or oil tanks).

The Risk of Power Outages

The most obvious drawback is vulnerability to power outages. During a winter storm or grid failure, an all-electric heating system will fail completely, leaving the property without its primary source of warmth.

This creates a critical point of failure, especially in climates with severe winters where losing heat can be a safety issue.

Grid Strain and Demand Charges

In commercial and industrial settings, large-scale electric heating can place a significant load on the electrical grid. This can lead to high "demand charges" from utility providers, which are fees based on the maximum amount of power drawn at any one time.

During cold snaps, widespread use of electric heat can strain the local grid, potentially contributing to brownouts or the need for costly infrastructure upgrades.

Understanding the Trade-offs

Choosing an electric heating system involves balancing its clean, simple operation against its fundamental costs and dependencies.

Upfront Simplicity vs. Long-Term Cost

Electric heaters are often simpler and cheaper to install than furnace systems that require ductwork, fuel lines, and ventilation. However, this lower initial investment is frequently offset by higher monthly operating costs over the life of the system.

On-Site Safety vs. Grid Dependency

Electric heating eliminates the on-site risks of carbon monoxide leaks or fuel combustion. This makes it an inherently safer option within the building itself. This internal safety is traded for an external dependency on a grid you do not control.

Point-of-Use Emissions vs. Source Emissions

An electric heater produces zero local emissions, which is a major benefit for indoor air quality. However, the environmental impact has simply been shifted to the power plant.

If your electricity is generated by burning coal or natural gas, your "clean" electric heat is still contributing to carbon emissions—just not inside your building. The true green credentials of electric heat are tied directly to how green your electricity provider is.

Making the Right Choice for Your Goal

To select the appropriate system, you must weigh these drawbacks against your specific priorities.

- If your primary focus is the lowest possible operating cost: Explore heating systems that use natural gas or, in some regions, heating oil, as they typically offer a lower cost per unit of heat.

- If your primary focus is on-site safety and air quality: Electric heating is a superior choice, but you must plan to mitigate high costs through excellent insulation, smart thermostats, and potentially smaller, zoned systems.

- If your primary focus is overall environmental impact: Electric heating is only the right choice if you can pair it with a renewable energy source, such as on-site solar panels or a utility provider that generates power from wind, solar, or hydro.

Ultimately, an informed decision requires looking beyond the appliance itself to understand the full economic and infrastructural system it operates within.

Summary Table:

| Drawback | Description |

|---|---|

| High Operational Cost | Electricity is often more expensive per unit of energy than fossil fuels, leading to higher long-term costs despite high efficiency. |

| Grid Dependence | Complete reliance on the electrical grid increases vulnerability to power outages and grid strain, especially in severe weather. |

| Environmental Impact | Zero local emissions, but overall impact depends on the power source; can be high if electricity comes from fossil fuels. |

| Upfront vs. Long-Term Trade-off | Lower installation costs may be offset by higher ongoing expenses, requiring careful financial planning. |

Struggling with high heating costs or unreliable systems in your lab? At KINTEK, we specialize in advanced high-temperature furnace solutions tailored to your unique needs. Leveraging exceptional R&D and in-house manufacturing, our product line—including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems—is designed for efficiency and reliability. With strong deep customization capabilities, we ensure precise performance to overcome drawbacks like energy inefficiency and downtime. Enhance your laboratory's productivity and reduce operational headaches—contact us today to discuss how our solutions can benefit you!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a high-performance muffle furnace required for the calcination of nanopowders? Achieve Pure Nanocrystals

- What substances are prohibited from being introduced into the furnace chamber? Prevent Catastrophic Failure

- What metals cannot be heated by induction? Understanding Material Suitability for Efficient Heating

- What environmental conditions are critical for SiOC ceramicization? Master Precise Oxidation & Thermal Control

- What is the role of a muffle furnace in the synthesis of water-soluble Sr3Al2O6? Precision in SAO Production