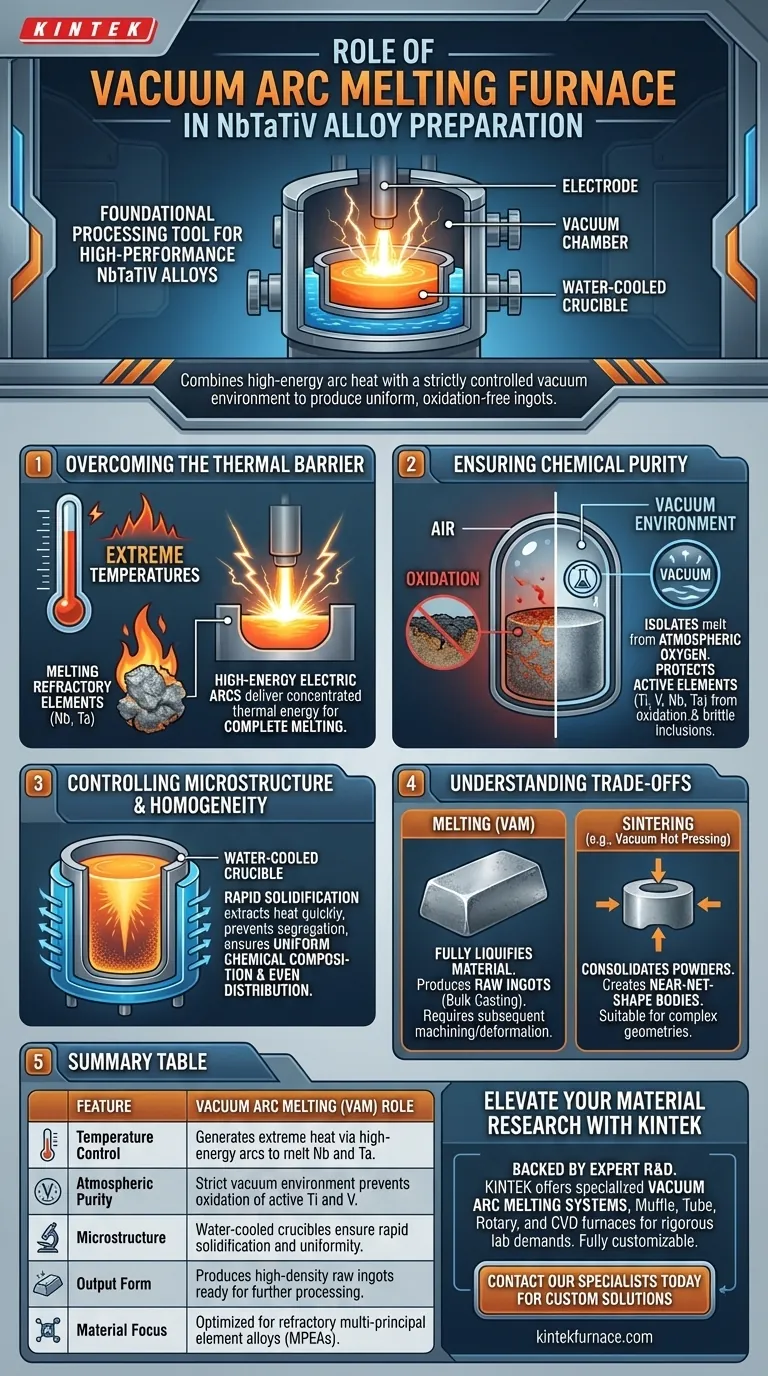

The Vacuum Arc Melting Furnace serves as the foundational processing tool for creating high-performance NbTaTiV alloys. It utilizes high-energy electric arcs to generate the extreme temperatures required to melt refractory elements like Niobium and Tantalum, while simultaneously employing a vacuum environment to prevent oxidation and a water-cooled crucible to control solidification.

Creating refractory multi-principal element alloys requires overcoming extreme melting points and high chemical reactivity. The Vacuum Arc Melting Furnace solves both challenges by combining high-energy arc heat with a strictly controlled vacuum environment to produce uniform, oxidation-free ingots.

Overcoming the Thermal Barrier

Generating Extreme Temperatures

The primary challenge in preparing NbTaTiV alloys is the refractory nature of its components. Elements like Niobium (Nb) and Tantalum (Ta) have exceptionally high melting points that conventional furnaces struggle to reach.

The Role of High-Energy Arcs

To bypass this limitation, the furnace employs high-energy electric arcs. This mechanism delivers concentrated thermal energy directly to the material, ensuring the complete melting of even the most heat-resistant elements in the mixture, such as Tungsten (W) or Tantalum.

Ensuring Chemical Purity

Protecting Active Elements

The alloy components Titanium (Ti) and Vanadium (V), along with Nb and Ta, are chemically active and prone to rapid oxidation at high temperatures. If exposed to air during melting, these elements would degrade, compromising the alloy's properties.

The Vacuum Environment

The furnace operates under a strict vacuum. This effectively isolates the melt from atmospheric oxygen. By preventing oxidation, the system preserves the integrity of the active elements and prevents the formation of brittle oxide inclusions within the alloy.

Controlling Microstructure and Homogeneity

Rapid Solidification

The design features a water-cooled copper crucible. This component is critical for extracting heat quickly from the molten metal.

Achieving Uniformity

The combination of intense arc mixing and the cooling capabilities of the crucible ensures the production of ingots with a uniform chemical composition. This rapid solidification helps prevent segregation, ensuring the NbTaTiV elements are evenly distributed throughout the matrix.

Understanding the Trade-offs

Melting vs. Sintering

It is important to distinguish this process from powder metallurgy techniques like vacuum hot pressing. While hot pressing applies mechanical pressure to consolidate powders and eliminate pores at lower temperatures, vacuum arc melting fully liquefies the material.

Geometry Limitations

The Vacuum Arc Melting Furnace is designed to produce raw ingots, known as "foundational equipment" for fabrication. Unlike hot pressing, which can create near-net-shape formed bodies, arc melting produces a bulk casting that typically requires subsequent machining or deformation processing to achieve a final shape.

Making the Right Choice for Your Goal

To ensure the successful preparation of your NbTaTiV alloy, consider your specific processing requirements:

- If your primary focus is elemental purity and homogeneity: Prioritize Vacuum Arc Melting to fully fuse refractory metals and eliminate segregation through liquid-state mixing.

- If your primary focus is near-net-shape formation: Acknowledge that Arc Melting produces raw ingots, and you may need to investigate powder metallurgy methods (like hot pressing) for complex geometries.

By leveraging the high-energy arc and vacuum protection, you ensure the successful synthesis of chemically complex, high-melting-point alloys.

Summary Table:

| Feature | Vacuum Arc Melting (VAM) Role |

|---|---|

| Temperature Control | Generates extreme heat via high-energy arcs to melt Nb and Ta. |

| Atmospheric Purity | Strict vacuum environment prevents oxidation of active Ti and V. |

| Microstructure | Water-cooled crucibles ensure rapid solidification and uniformity. |

| Output Form | Produces high-density raw ingots ready for further processing. |

| Material Focus | Optimized for refractory multi-principal element alloys (MPEAs). |

Elevate Your Material Research with KINTEK

Precision in refractory alloy synthesis requires more than just heat—it requires a controlled, high-performance environment. Backed by expert R&D and world-class manufacturing, KINTEK offers specialized Vacuum Arc Melting systems, Muffle, Tube, Rotary, and CVD furnaces designed to meet the rigorous demands of your lab. Whether you are developing complex NbTaTiV alloys or advanced ceramics, our systems are fully customizable to your unique processing needs.

Ready to achieve superior elemental purity and homogeneity?

Contact our specialists today to find your custom furnace solution!

Visual Guide

References

- Chan-Ho Lee, Saryu Fensin. Deformation Behaviors in Single BCC‐Phase Refractory Multi‐Principal Element Alloys under Dynamic Conditions. DOI: 10.1002/advs.202508180

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Vacuum Heat Treat Sintering Furnace Molybdenum Wire Vacuum Sintering Furnace

- Vacuum Heat Treat Sintering and Brazing Furnace

People Also Ask

- What are the core advantages of an induction furnace for magnesium powder? Achieve 20x Higher Yield

- What materials can be processed using induction technology? A Guide to Metals, Alloys, and Beyond

- What is the primary role of a vacuum pump in induction brazing? Achieve Pure, Contamination-Free Research Results

- What factors should be considered when selecting an induction melting furnace for a business? Maximize Efficiency and ROI

- Why are independent melting furnaces and injection chambers required for cold chamber die casting machines? Explained

- What role does an arc melting furnace play in the synthesis of Ce2(Fe, Co)17? Achieve Precision Alloy Homogeneity

- How do vacuum induction furnaces differ from standard induction furnaces? Choose the Right Furnace for Your Metal Purity Needs

- What components are involved in a vacuum system for induction furnaces? Optimize Your High-Temperature Processing