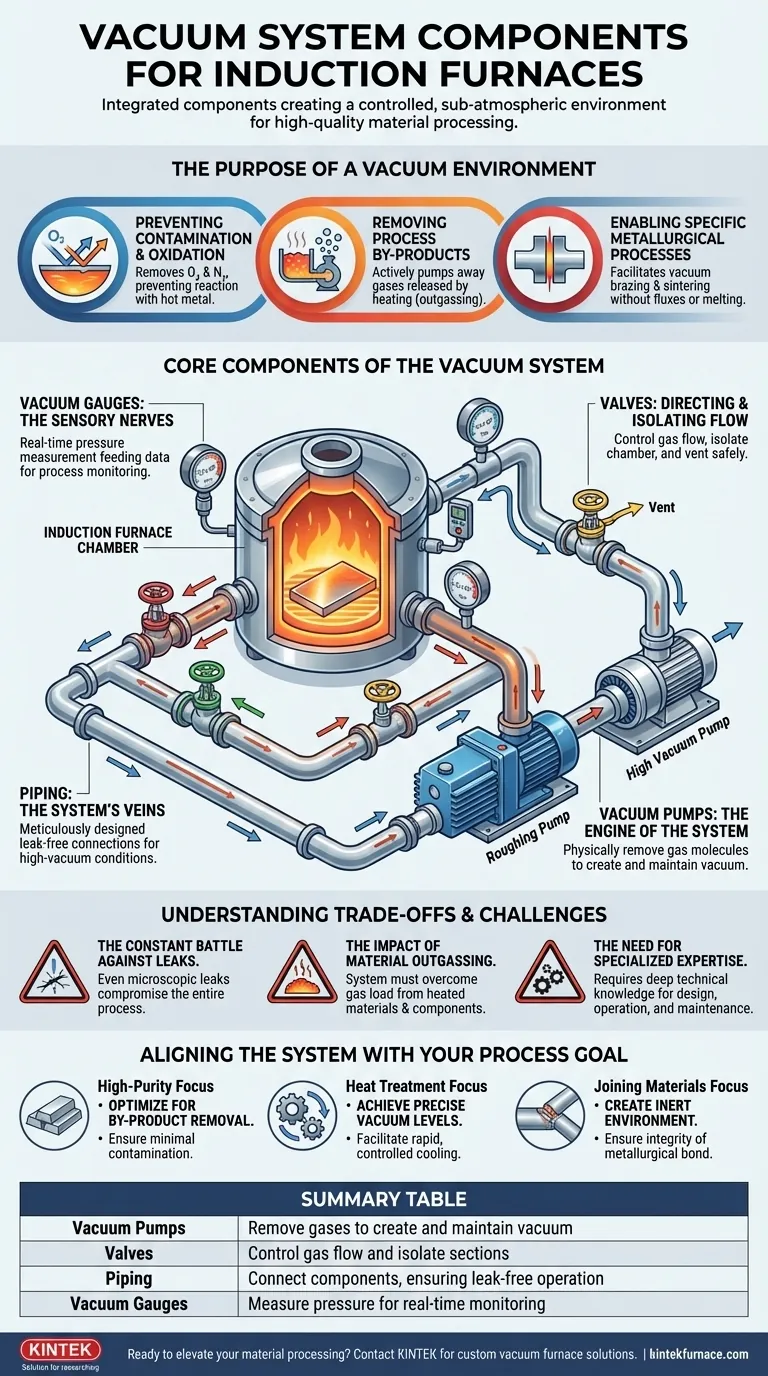

At its core, a vacuum system for an induction furnace is an integrated set of components designed to remove air and other gases from the furnace chamber. The primary parts include one or more vacuum pumps, a series of valves to control gas flow, the connecting pipes, and vacuum gauges to measure the pressure. These elements work together to create a controlled, sub-atmospheric environment essential for high-quality material processing.

The individual components of a vacuum system are less important than how they function together. The true goal is not just to create a vacuum, but to engineer a specific environment that prevents contamination, removes by-products, and enables metallurgical processes that are impossible in open air.

The Purpose of a Vacuum Environment

Before examining the components, it's critical to understand why a vacuum is necessary. The vacuum itself is not the product; it is the environment that enables a superior result.

Preventing Contamination and Oxidation

The most fundamental role of a vacuum is to remove atmospheric gases, primarily oxygen and nitrogen. This prevents the hot metal from reacting with the air, which would otherwise cause unwanted oxidation and introduce impurities.

Removing Process By-products

Heating materials, especially those with binders or surface contaminants, releases gases—a process known as outgassing. The vacuum system actively pumps these gaseous by-products away, resulting in a final product with higher purity and superior structural integrity.

Enabling Specific Metallurgical Processes

Certain processes are only possible in a vacuum. For example, vacuum brazing joins parts using a filler metal that flows cleanly without fluxes, and vacuum sintering fuses metal powders into a solid mass without melting them.

Core Components of the Vacuum System

Each component plays a distinct and critical role in creating, controlling, and measuring the vacuum level within the furnace.

Vacuum Pumps: The Engine of the System

The pumps are the heart of the system, responsible for physically removing gas molecules from the furnace chamber. A system often uses multiple pumps in stages to efficiently reach the desired low pressure.

Valves: Directing and Isolating Flow

Valves are the control gates of the system. They are used to isolate the furnace chamber from the pumps, control the rate of evacuation, and allow the chamber to be safely vented back to atmospheric pressure after the process is complete.

Piping: The System's Veins

The network of pipes connects the furnace chamber, pumps, and valves. These must be meticulously designed and constructed from appropriate materials to handle high-vacuum conditions without leaking or introducing contamination of their own.

Vacuum Gauges: The Sensory Nerves

You cannot control what you cannot measure. Vacuum gauges are specialized sensors that provide a continuous, real-time measurement of the pressure inside the furnace. This data is fed to the control panel, allowing for precise process monitoring and automation.

Understanding the Trade-offs and Challenges

While powerful, vacuum systems require specialized knowledge for design, operation, and maintenance. Ignoring their complexities leads to poor results and equipment failure.

The Constant Battle Against Leaks

Even a microscopic leak can prevent the system from reaching the target vacuum level, introducing contaminants and compromising the entire process. Leak detection and prevention are constant operational concerns.

The Impact of Material Outgassing

The materials being processed and even the internal furnace components can release trapped gases when heated. The vacuum system must be powerful enough to overcome this "gas load" to maintain the required pressure.

The Need for Specialized Expertise

Selecting the right combination of pumps, valves, and gauges for a specific application requires deep technical knowledge. Likewise, proper maintenance is not a trivial task and is essential for reliable, long-term performance.

Aligning the System with Your Process Goal

The design of a vacuum system should be driven by the intended application. Your primary goal dictates which performance characteristics are most important.

- If your primary focus is high-purity materials: Your system must be optimized for removing by-products and preventing any atmospheric leaks to ensure minimal contamination.

- If your primary focus is heat treatment (e.g., quenching or hardening): The system's ability to achieve precise vacuum levels and facilitate rapid, controlled cooling is the most critical factor.

- If your primary focus is joining materials (e.g., brazing or sintering): The system's main job is to create a chemically inert, oxygen-free environment that ensures the integrity of the metallurgical bond.

Understanding how these components create a controlled environment is the first step toward mastering your material processing outcomes.

Summary Table:

| Component | Function |

|---|---|

| Vacuum Pumps | Remove gases to create and maintain vacuum |

| Valves | Control gas flow and isolate sections |

| Piping | Connect components, ensuring leak-free operation |

| Vacuum Gauges | Measure pressure for real-time monitoring |

Ready to elevate your material processing with a custom vacuum system? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability ensures we precisely meet your unique experimental requirements, delivering enhanced purity, efficiency, and reliability. Contact us today to discuss how we can optimize your lab's performance!

Visual Guide

Related Products

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Molybdenum Vacuum Heat Treat Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the functions of a high-vacuum furnace for CoReCr alloys? Achieve Microstructural Precision and Phase Stability

- What are the components of a vacuum furnace? Unlock the Secrets of High-Temperature Processing

- What are the general operational features of a vacuum furnace? Achieve Superior Material Purity & Precision

- What is the vacuum heat treatment process? Achieve Superior Surface Quality and Material Performance

- What role does a high-temperature vacuum heat treatment furnace play in LP-DED? Optimize Alloy Integrity Today