For preparing magnesium powder, the primary advantage of an induction heating furnace is its ability to generate an electromagnetic stirring effect within the molten magnesium. This action reshapes the liquid's surface into a hemisphere, dramatically increasing the effective evaporation area and boosting the powder yield by more than 20 times compared to a resistance furnace.

The choice between induction and resistance heating for this process is not merely about temperature; it's about physics. Induction heating actively manipulates the molten material to maximize evaporation efficiency, while resistance heating is a passive method that fundamentally limits the potential yield.

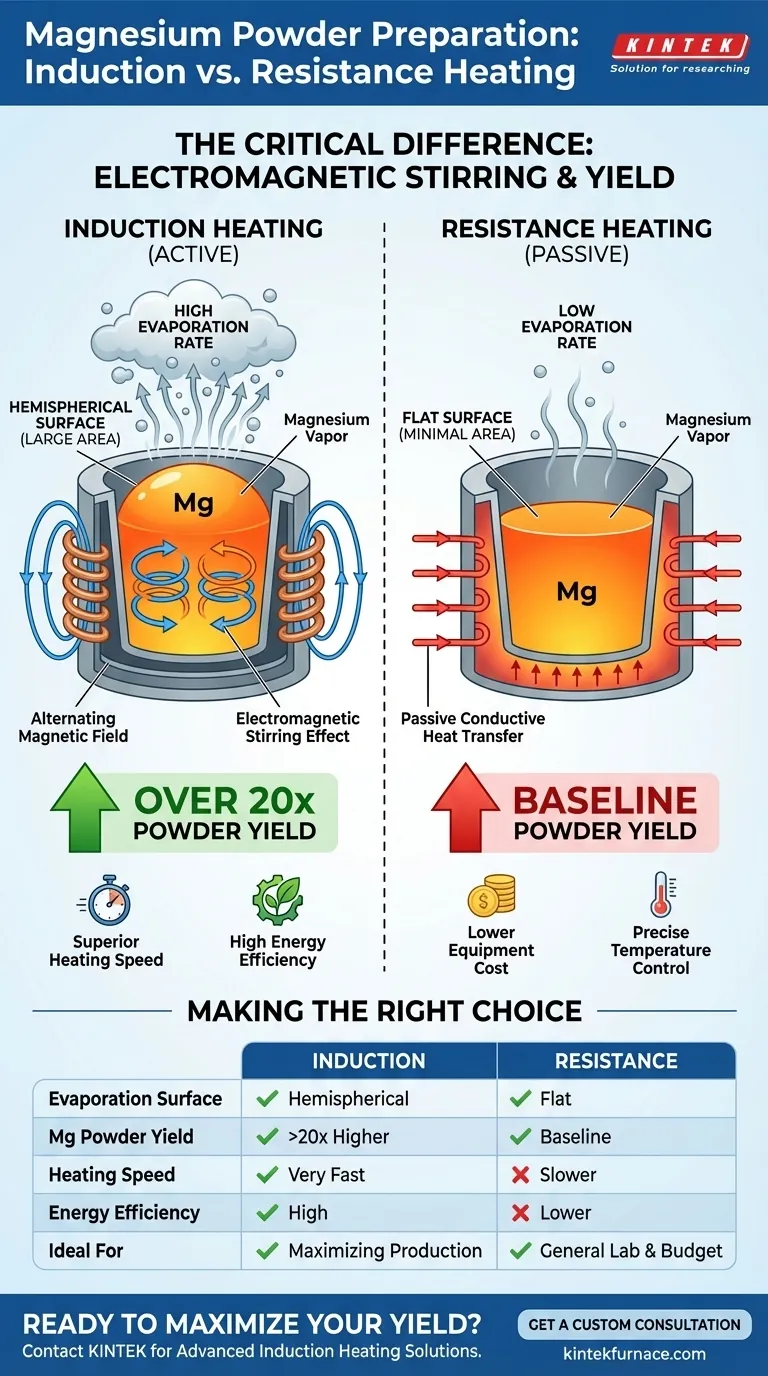

The Critical Difference: How Heating Method Impacts Evaporation

The vast difference in powder yield comes down to how each furnace interacts with the molten magnesium. This interaction directly influences the rate at which the magnesium can evaporate and then be condensed into powder.

The Electromagnetic Stirring Effect (Induction)

An induction furnace works by creating a powerful, alternating magnetic field. This field induces eddy currents within the conductive magnesium, generating heat directly inside the material.

A crucial secondary outcome of these currents is a physical force that vigorously stirs the molten metal.

The Hemispherical Advantage

This electromagnetic stirring forces the surface of the molten magnesium to change shape from a flat plane into a hemisphere.

This convex, hemispherical shape has a much larger surface area than a flat one for the same volume of liquid. This massively increases the available area for evaporation, which is the single most important factor for a high yield in this process.

Passive Heating (Resistance)

A resistance furnace heats the crucible from the outside using resistive heating elements. The heat then transfers passively and conductively to the magnesium inside.

This method does not create any stirring force. The surface of the molten magnesium remains flat, presenting the minimum possible surface area for evaporation and thereby throttling the entire process.

Secondary Performance Advantages of Induction Heating

Beyond the game-changing effect on evaporation, induction furnaces offer other key operational benefits.

Superior Heating Speed

Induction heating is incredibly fast, allowing the furnace to reach the target temperature in a very short time. This improves experimental efficiency and overall process throughput.

High Energy Efficiency

Because heat is generated directly within the magnesium itself, very little energy is wasted heating the surrounding furnace components or atmosphere. This targeted heating leads to significantly higher energy utilization.

Understanding the Trade-offs: When to Consider a Resistance Furnace

Despite its clear disadvantages for magnesium powder production, the resistance furnace remains a valuable tool for other applications due to its distinct benefits.

Lower Equipment Cost

Resistance furnaces have a simpler structure and use more mature technology. This results in substantially lower manufacturing, maintenance, and initial acquisition costs, making them ideal for labs with limited budgets.

Precise Temperature Control

For conventional experiments that do not rely on evaporation dynamics, resistance furnaces often provide very accurate and stable temperature control. The heating rate can be adjusted precisely to meet specific experimental profiles.

Simplicity of Operation

The technology behind resistance heating is well-established and straightforward. These furnaces are typically easier to operate and do not require specialized training, making them suitable for general laboratory use.

Making the Right Choice for Your Goal

Your choice of furnace should be dictated entirely by the primary objective of your process.

- If your primary focus is maximizing magnesium powder yield and throughput: The induction heating furnace is the unequivocally superior choice due to the massive yield increase from the electromagnetic stirring effect.

- If your primary focus is minimizing initial capital expenditure: A resistance furnace offers the lowest-cost entry point, but you must be prepared to accept a drastically lower production efficiency.

- If your primary focus is general-purpose lab heating with precise control: For most conventional heating experiments, a resistance furnace provides excellent performance, control, and value.

Ultimately, understanding the underlying physics of your specific application is the key to selecting the most effective tool.

Summary Table:

| Feature | Induction Furnace | Resistance Furnace |

|---|---|---|

| Evaporation Surface | Hemispherical (Large Area) | Flat (Minimal Area) |

| Mg Powder Yield | >20x Higher | Baseline |

| Heating Method | Internal, Direct (Electromagnetic) | External, Passive (Conductive) |

| Heating Speed | Very Fast | Slower |

| Energy Efficiency | High | Lower |

| Ideal For | Maximizing Powder Production | General Lab Heating, Budget-Conscious Applications |

Ready to maximize your magnesium powder yield with induction heating technology?

At KINTEK, we specialize in designing and manufacturing advanced laboratory heating solutions. Our induction heating systems are engineered to deliver the electromagnetic stirring effect critical for achieving ultra-high evaporation rates and powder yields.

Why choose KINTEK for your high-temperature processing needs?

- Expertise: Backed by expert R&D and manufacturing, we provide tailored solutions for unique material science challenges like magnesium powder preparation.

- Product Range: We offer a full range of high-performance furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable to your specific process requirements.

Contact our experts today to discuss how our induction heating technology can revolutionize your lab's efficiency and output. Let's achieve your goals together.

➡️ Get a Custom Solution Consultation Now

Visual Guide

Related Products

- Vacuum Induction Melting Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

People Also Ask

- What are the common applications of Vacuum Induction Melting? Essential for High-Performance Metals and Alloys

- What are some common applications of vacuum induction melting and casting (VIM&C)? Essential for Aerospace, Medical, and Nuclear Industries

- How does vacuum melting technology contribute to sustainability? Boost Durability and Recycling Efficiency

- Why is a Vacuum Induction Melting (VIM) furnace essential? Unlock Purity for Aerospace and Semiconductors

- How has vacuum smelting impacted the development of superalloys? Unlock Higher Strength and Purity