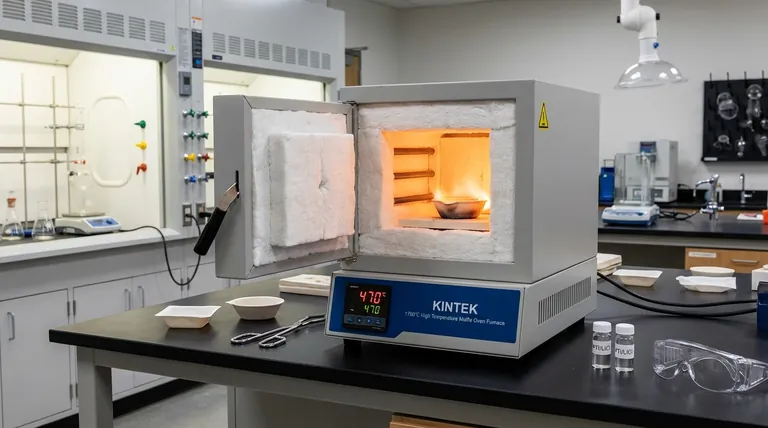

The role of a Muffle Furnace in synthesizing poly(triazine imide) (PTI/LiCl) is to function as a precise thermal reactor. It generates the stable high-temperature environment—specifically around 470 °C—required to melt lithium chloride and potassium chloride salts, enabling the full reaction of melamine into a crystalline carbon-nitrogen framework.

By strictly controlling heating and cooling ramps, the Muffle Furnace transforms a volatile chemical reaction into a controlled crystallization process. It manages the interplay between the molten salt medium and the ammonia gas generated during synthesis to ensure the production of high-quality crystalline carbon nitride materials.

The Mechanism of Molten Salt Synthesis

Establishing the Reaction Medium

The primary function of the furnace is to reach and maintain the melting point of the salt mixture.

At approximately 470 °C, the lithium chloride (LiCl) and potassium chloride (KCl) mixture transitions into a molten state. This liquid salt bath acts as a solvent, allowing melamine molecules to dissolve and react more uniformly than they would in a solid-state reaction.

Facilitating Framework Formation

Once the salts are molten, the Muffle Furnace provides the consistent thermal energy required for polymerization.

The melamine reacts within this liquid medium to form the poly(triazine imide) structure. The stability of the furnace temperature is critical here to prevent partial reactions or the degradation of the forming polymer.

Controlling Material Properties

Ensuring High Crystallinity

The quality of PTI/LiCl is defined by its crystalline structure, which is directly dictated by the furnace's programming.

The Muffle Furnace uses precise heating and cooling programs to control the rate of crystallization. A controlled thermal profile allows the carbon-nitrogen framework to order itself systematically, resulting in high crystallinity rather than an amorphous solid.

Leveraging Gas Evolution

During the reaction, ammonia gas is generated as a byproduct of melamine polymerization.

The Muffle Furnace facilitates this process by maintaining the environment where this gas evolution assists in framework formation. Under the controlled pressure and temperature within the furnace, the ammonia acts as a structural guide before being released.

Critical Process Variables

The Necessity of Program Control

The difference between a high-quality semiconductor and a useless powder often lies in the cooling phase.

If the furnace cools too rapidly, the molten salts solidify before the PTI framework can fully crystallize. The Muffle Furnace’s ability to execute a slow, programmed cooldown is essential for "freezing" the desired structure in place.

Stability at 470 °C

Temperature fluctuations at the peak of the reaction can introduce defects.

The Muffle Furnace must hold the target temperature of 470 °C with minimal variance. Deviations can lead to incomplete melting of the salts or inconsistent integration of the lithium ions into the PTI framework.

Optimizing Your Synthesis Protocol

To maximize the quality of your PTI/LiCl synthesis, adjust your furnace parameters based on your specific requirements:

- If your primary focus is Structural Perfection: Prioritize the cooling program, ensuring a slow ramp-down to maximize the ordering of the carbon-nitrogen framework.

- If your primary focus is Reaction Completeness: Ensure the dwell time at 470 °C is sufficient for the LiCl/KCl salts to fully melt and for the melamine to react completely.

The Muffle Furnace is not just a heater; it is the instrument that orchestrates the delicate phase transition from raw precursors to advanced crystalline materials.

Summary Table:

| Process Phase | Furnace Function | Impact on PTI/LiCl Quality |

|---|---|---|

| Salt Melting | Precise dwell at 470 °C | Ensures uniform liquid solvent for precursor dissolution |

| Polymerization | Consistent thermal stability | Facilitates melamine reaction into C-N framework |

| Crystallization | Programmed slow cooling | Maximizes structural ordering and framework perfection |

| Gas Management | Controlled environment | Stabilizes framework formation during ammonia evolution |

Elevate Your Material Synthesis with KINTEK

Precision is the difference between an amorphous powder and a high-performance semiconductor. KINTEK provides advanced, customizable thermal solutions—including Muffle, Tube, Rotary, Vacuum, and CVD systems—engineered to meet the rigorous demands of molten salt reactions and crystalline framework formation.

Backed by expert R&D and world-class manufacturing, our high-temperature furnaces deliver the stability and programmable control required for your most sensitive laboratory protocols.

Ready to optimize your synthesis results? Contact KINTEK today to discuss your unique research needs and discover how our equipment can transform your material quality.

References

- Magnus Pauly, Paul A. Maggard. Coordination of copper within a crystalline carbon nitride and its catalytic reduction of CO <sub>2</sub>. DOI: 10.1039/d4dt00359d

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What cooling strategy should be followed in a muffle furnace for BiFeO3 nanofibers? Ensure Structural Integrity

- What precautions should be taken when melting samples with alkaline substances? Safeguard Your Furnace from Corrosion

- What role does a Muffle Furnace play in Bouligand ceramic aerogel production? Essential Ceramization & Solidification

- How does a laboratory muffle furnace facilitate the pyrolysis of Plum Stone Biochar? Optimize Your Carbon Production

- What materials should be avoided when using a muffle furnace? Prevent Hazards and Extend Equipment Life

- What is a digital muffle furnace and what are its primary functions? Achieve Pure, High-Temperature Processing

- What is the primary technical function of a Muffle Furnace in CoMn2O4 synthesis? Achieve Precise Nano-Spinel Calcination

- What role does a laboratory box resistance furnace play in lunar ISRU? Advancing Space Construction with KINTEK