At its core, a digital muffle furnace is a high-temperature oven designed to achieve one critical goal: heating a material without contaminating it. It accomplishes this by placing the sample within a "muffle"—an isolated chamber that separates it from the heating elements and any potential byproducts of combustion. The "digital" component refers to its modern electronic controller, which allows for extremely precise and repeatable temperature management for processes like ashing, heat treating, and sintering.

The defining characteristic of a muffle furnace is its use of indirect heating. By separating the material from the heat source, it ensures that processes requiring both high temperatures and absolute purity can be performed reliably and without contamination.

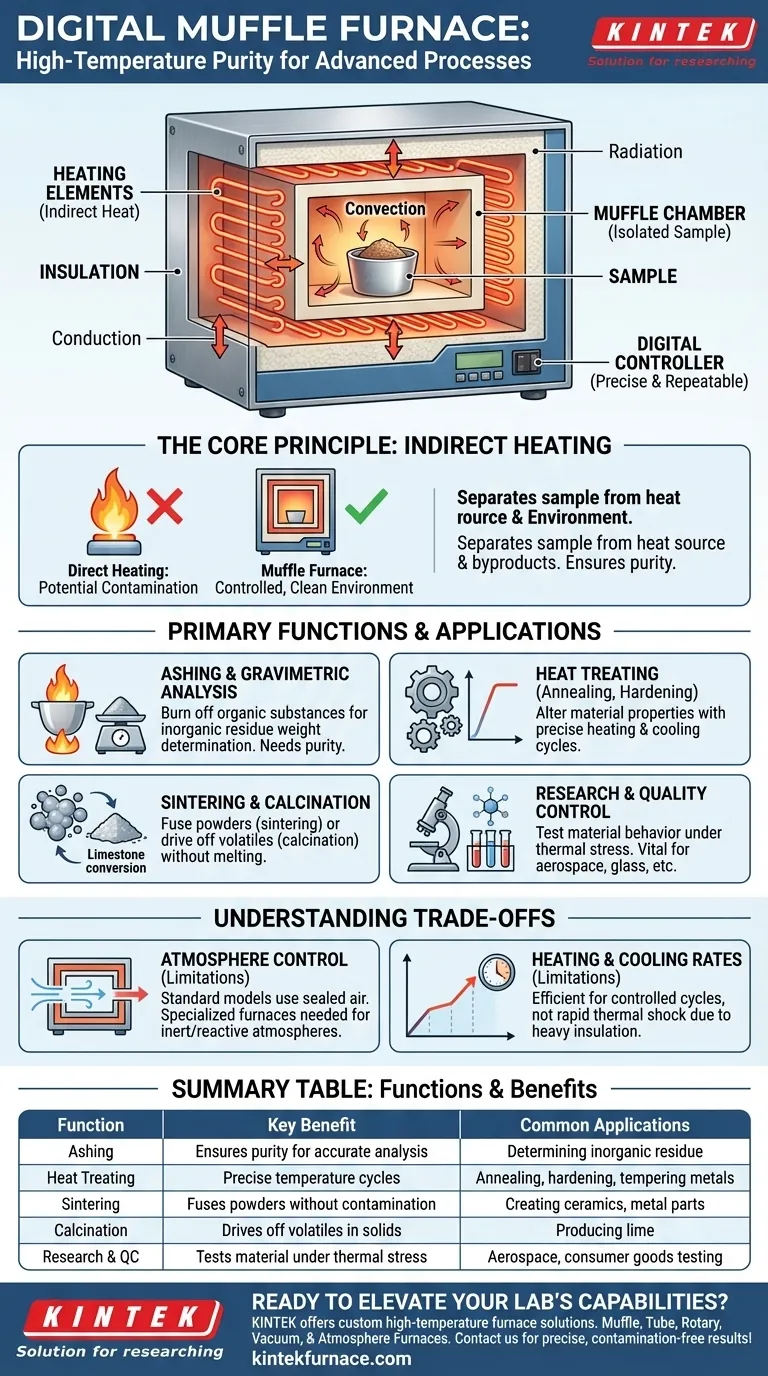

The Core Principle: Indirect Heating for Purity

A muffle furnace operates on a simple but powerful principle. Unlike a flame or a simple kiln where the material is exposed directly to the heat source, a muffle furnace creates a controlled, clean heating environment.

What Is the "Muffle"?

The term "muffle" refers to the insulated, enclosed chamber that holds the material being heated. This chamber is typically made of a high-temperature ceramic or metallic alloy.

The heating elements, such as electrical resistance coils, are positioned on the outside of this chamber or embedded within its walls.

How Heat Is Transferred

Because there is no direct contact with the heating elements, heat is transferred to the sample inside the muffle through a combination of three methods:

- Conduction: Heat moves through the walls of the muffle.

- Convection: The air inside the chamber circulates, distributing heat evenly.

- Radiation: The hot interior walls of the chamber radiate thermal energy onto the sample.

Why This Isolation Matters

This separation is the furnace's primary advantage. It prevents any contaminants—such as gases from fuel combustion in older models or microscopic particles shed from the heating elements in electric models—from interacting with the sample. This guarantees the chemical and physical integrity of the material being tested or treated.

Key Applications and Functions

The unique combination of high heat and a non-contaminating environment makes the digital muffle furnace essential across many scientific and industrial fields.

Ashing and Gravimetric Analysis

Ashing is the process of burning off all organic substances in a sample to determine the weight of the non-combustible inorganic residue (ash). The furnace's precise temperature control and clean environment are critical for accurate quantitative analysis.

Heat Treating, Annealing, and Hardening

In metallurgy and materials science, a muffle furnace is used to alter a material's properties. Processes like annealing (softening), hardening, and tempering metals require exact heating and cooling cycles that a digital controller can execute perfectly.

Sintering and Calcination

Sintering is the process of fusing powders into a solid mass using heat, without melting it. This is fundamental in creating ceramics and certain metal parts. Calcination involves heating a solid to drive off volatile components, such as turning limestone into lime. Both require the high, controlled heat of a muffle furnace.

Research and Quality Control

Laboratories use these furnaces to test how materials behave under extreme thermal stress. This data is vital for ensuring the quality and safety of everything from aerospace components to consumer glassware.

Understanding the Trade-offs

While incredibly versatile, a digital muffle furnace is not a universal solution. Understanding its limitations is key to using it effectively.

Atmosphere Control

A standard muffle furnace operates with the air that is sealed inside its chamber. It does not control the atmospheric composition. If a process requires an inert atmosphere (like argon) or a reactive one, a specialized furnace with gas inlet and outlet ports is necessary.

Heating and Cooling Rates

The heavy insulation required for temperature stability means that muffle furnaces do not heat or cool instantaneously. While modern designs are highly efficient, they are not intended for processes requiring rapid thermal shock. Their strength lies in controlled, sustained heating cycles.

Chamber Size and Sample Throughput

Muffle furnaces are typically front-loading box ovens, which limits the size and shape of the objects that can be processed. They are best suited for batch processing in a lab or small-scale production, not for continuous industrial throughput.

Making the Right Choice for Your Process

Selecting the right heating equipment depends entirely on the requirements of your task.

- If your primary focus is quantitative analysis (like ashing): The absolute purity and precise, programmable temperature control of a digital muffle furnace are non-negotiable for accurate results.

- If your primary focus is materials science (like sintering or heat treating): The furnace's non-contaminating environment and ability to execute complex heating cycles are essential for creating materials with specific, repeatable properties.

- If your primary focus is simply bulk heating without purity concerns: A simpler, direct-heat kiln or furnace might be a more cost-effective and faster solution.

Understanding this core principle of controlled, isolated heat is the key to leveraging the muffle furnace for any advanced high-temperature application.

Summary Table:

| Function | Key Benefit | Common Applications |

|---|---|---|

| Ashing | Ensures purity for accurate gravimetric analysis | Determining inorganic residue in samples |

| Heat Treating | Allows precise temperature cycles for material properties | Annealing, hardening, and tempering metals |

| Sintering | Fuses powders without contamination | Creating ceramics and metal parts |

| Calcination | Drives off volatile components in solids | Producing lime from limestone |

| Research & QC | Tests material behavior under thermal stress | Aerospace and consumer goods testing |

Ready to elevate your lab's capabilities with a custom high-temperature furnace? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced solutions tailored to your needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization to meet your unique experimental requirements. Contact us today to discuss how we can help you achieve precise, contamination-free results in ashing, sintering, and more!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- How does a muffle furnace contribute to kaolin-modified biochar? Optimize Pyrolysis & Mineral Integration

- How do repeat sintering processes and specialized sintering molds address the technical challenges of manufacturing oversized flywheel rotor components? Expand Scale and Integrity

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength

- What role does a muffle furnace play in analyzing the combustion residues? Optimize Your Composite Char Analysis

- Why is a muffle furnace used to determine the ash content of biochar? Master Your Material Purity Analysis