In the heat treatment of Zr-2.5%Nb pressure tube samples, the laboratory tube furnace acts as a precision instrument for driving critical microstructural evolution. Its primary role is to provide a stable, controlled thermal field that facilitates annealing and recrystallization, specifically enabling the transformation of grain structures within the 550°C to 800°C temperature range.

The core function of this apparatus is not simply heating, but rather the controlled alteration of the material's physical architecture. By converting elongated grains into equiaxed grains, the furnace allows researchers to quantitatively evaluate how microstructure dictates the mechanical anisotropy of the pressure tube material.

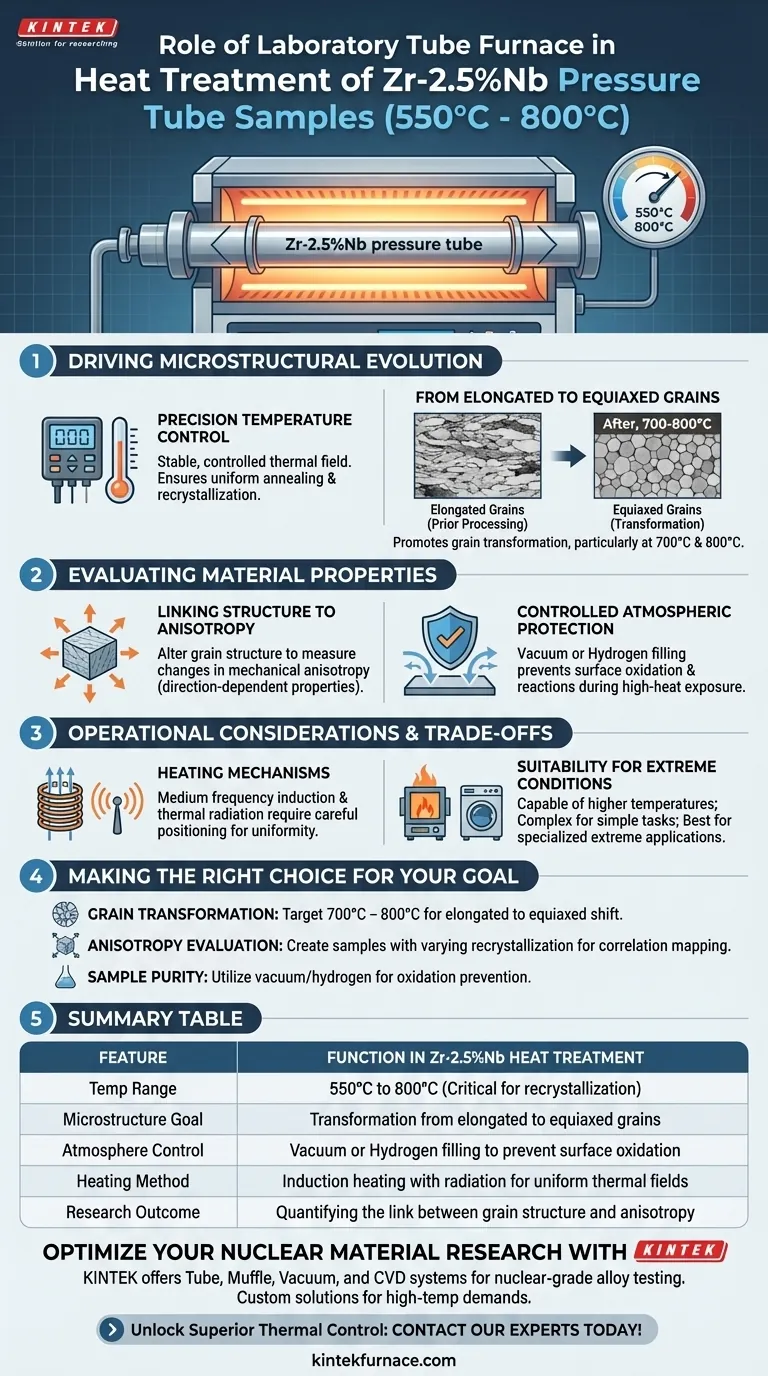

Driving Microstructural Evolution

Precision Temperature Control

The laboratory tube furnace utilizes a high-precision control system to maintain exact temperatures.

For Zr-2.5%Nb samples, maintaining a specific thermal environment is essential. This stability ensures that the annealing or recrystallization processes occur uniformly across the sample.

From Elongated to Equiaxed Grains

The most significant role of the furnace in this context appears at higher temperatures, specifically around 700°C and 800°C.

At these levels, the thermal field promotes the transformation of the sample's microstructure. The grains, originally elongated due to prior processing, transform into equiaxed grains (grains that are roughly equal in length, width, and height).

Evaluating Material Properties

Linking Structure to Anisotropy

The ultimate goal of this heat treatment is to understand mechanical behavior.

Zr-2.5%Nb pressure tubes often exhibit mechanical anisotropy, meaning their mechanical properties differ depending on the direction of the load. By using the furnace to alter the grain structure, researchers can measure exactly how microstructural evolution changes this anisotropy.

Controlled Atmospheric Protection

Beyond temperature, the tube furnace plays a vital role in protecting the sample surface.

These furnaces often operate with specific atmospheres. For example, the system may be vacuumed and then filled with hydrogen or other protective gases. This prevents unwanted oxidation or chemical reactions that could compromise the integrity of the Zr-2.5%Nb alloy during high-heat exposure.

Operational Considerations and Trade-offs

Heating Mechanisms and Radiation

Understanding how the heat is delivered is critical for experiment design.

Many advanced tube furnaces operate on the principle of medium frequency induction heating. This generates high temperatures in a susceptor (such as a tungsten crucible) located within the coil.

The heat is then transferred to the sample via thermal radiation. While efficient, this requires careful positioning of the sample to ensure the thermal field is truly uniform, as radiation relies on line-of-sight and surface properties.

Suitability for Extreme Conditions

Tube furnaces are generally capable of achieving higher temperatures than many alternative standard heating systems.

However, this capability comes with the complexity of managing vacuum seals and gas flows. If the objective is simple low-temperature drying, this equipment may be over-engineered. It is best reserved for specialized applications requiring extreme thermal conditions and atmospheric control.

Making the Right Choice for Your Goal

To maximize the utility of a laboratory tube furnace for Zr-2.5%Nb samples, align your settings with your specific research objectives:

- If your primary focus is Grain Transformation: Target the 700°C to 800°C range to actively promote the shift from elongated to equiaxed grains.

- If your primary focus is Anisotropy Evaluation: Use the furnace to create samples with varying degrees of recrystallization to map the correlation between grain shape and mechanical directionality.

- If your primary focus is Sample Purity: Utilize the vacuum and hydrogen-filling capabilities to prevent surface oxidation during the annealing process.

The laboratory tube furnace is the definitive tool for isolating the relationship between thermal history, grain structure, and mechanical performance in nuclear-grade alloys.

Summary Table:

| Feature | Function in Zr-2.5%Nb Heat Treatment |

|---|---|

| Temp Range | 550°C to 800°C (Critical for recrystallization) |

| Microstructure Goal | Transformation from elongated to equiaxed grains |

| Atmosphere Control | Vacuum or Hydrogen filling to prevent surface oxidation |

| Heating Method | Induction heating with radiation for uniform thermal fields |

| Research Outcome | Quantifying the link between grain structure and anisotropy |

Optimize Your Nuclear Material Research with KINTEK

Precision heat treatment is the backbone of microstructural analysis. KINTEK provides industry-leading Tube, Muffle, Vacuum, and CVD systems designed to meet the rigorous demands of nuclear-grade alloy testing. Whether you are studying grain transformation at 800°C or require a customizable atmosphere for material purity, our expert R&D and manufacturing teams deliver the high-temp solutions you need.

Unlock superior thermal control for your laboratory—Contact our experts today to customize your high-temperature furnace!

Visual Guide

References

- Arnomitra Chatterjee, R.N. Singh. Exploring Anisotropy in Zr-2.5%Nb Pressure Tube Material through Hardness Measurements: Role of Microstructure and Hydrogen Concentration. DOI: 10.1007/s11665-025-11744-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- 1200℃ Split Tube Furnace Laboratory Quartz Tube Furnace with Quartz Tube

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- What role does a high-temperature tube furnace play in lignin carbonization? Precision Heating for Porous Carbon

- How does a tube furnace ensure the quality of carbon materials? Precision Control for Hydrochar to Pyrochar Conversion

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- What advantages does a fluidized bed vertical tube furnace offer in terms of operation? Unlock Superior Heat Transfer and Uniformity

- What role does a tube furnace play in the preparation of biochar-filled PVC composite precursors? Expert Synthesis Guide

- What role does a tube furnace play in the high-temperature heat treatment stage of catalyst fabrication?

- How does a three-zone furnace improve process control? Achieve Precise Temperature Uniformity and Gradients

- How does a vacuum tube type experimental electric furnace work? Master Precise Heat Treatment in Controlled Environments