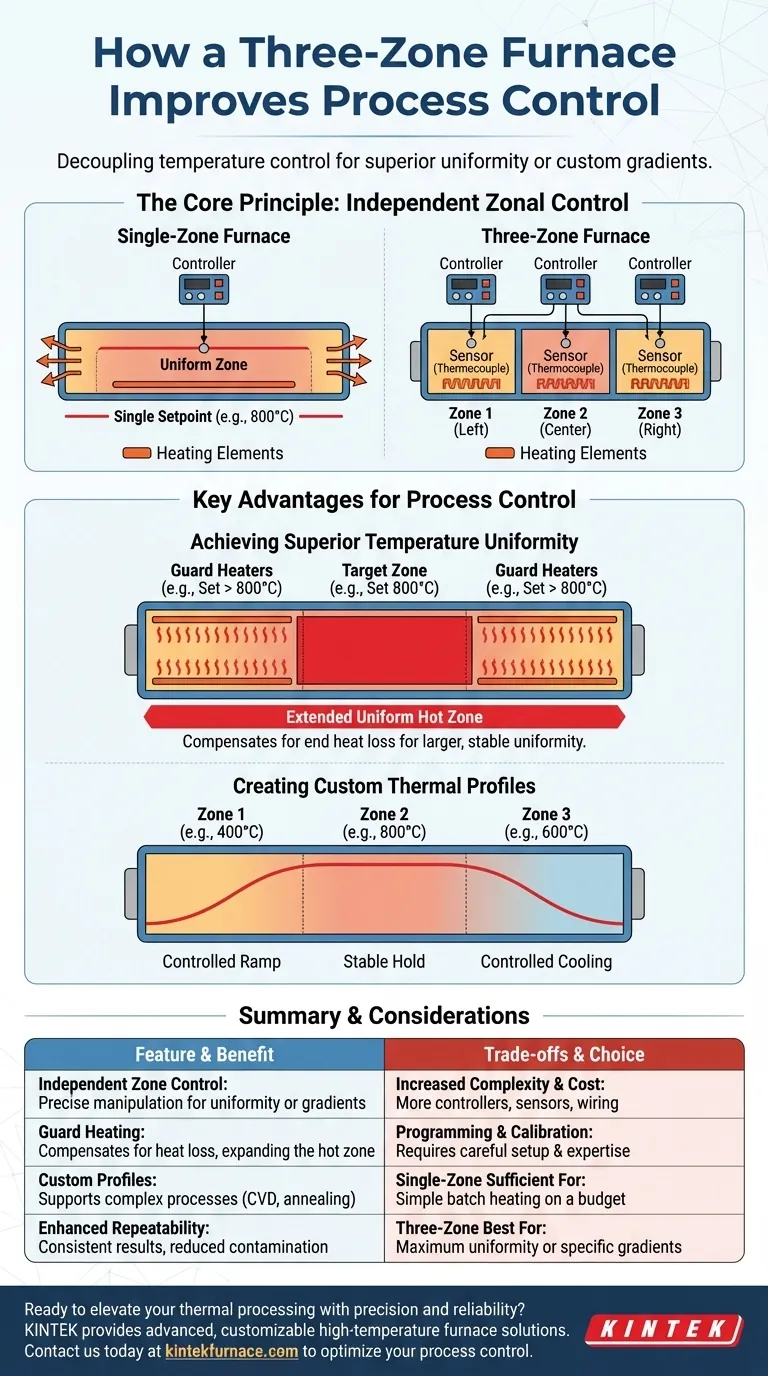

At its core, a three-zone furnace improves process control by dividing a single chamber into three distinct sections, each with its own independent heating elements, sensor, and controller. This design allows you to move beyond simple heating and precisely manipulate the thermal environment, either to create exceptional temperature uniformity or to establish a specific temperature gradient across the length of the furnace.

The fundamental advantage of a three-zone furnace is its ability to decouple temperature control. This allows it to actively compensate for heat loss to achieve superior uniformity or, alternatively, create complex thermal profiles that are impossible in a single-zone system.

The Core Principle: From Unified to Zonal Control

To understand the benefit, it's essential to compare a three-zone furnace to its single-zone counterpart. The difference in design philosophy is what unlocks its advanced capabilities.

The Anatomy of a Three-Zone Furnace

A three-zone furnace consists of a central heating zone and two end zones within a single process tube or chamber.

Each of these three zones is equipped with its own thermocouple (temperature sensor) and a dedicated controller that manages its specific heating elements.

Independent vs. Unified Heating

In a standard single-zone furnace, one controller attempts to heat the entire chamber to a single setpoint. This is simple but fundamentally flawed for precision work.

In a three-zone furnace, the controllers work in concert. This independent control is the key to its superior performance, allowing for two primary modes of operation: achieving near-perfect uniformity or creating an intentional gradient.

Key Advantages for Process Control

The ability to manage each zone independently translates directly into more consistent, repeatable, and sophisticated thermal processing.

Achieving Superior Temperature Uniformity

Heat naturally escapes from the ends of any furnace tube. In a single-zone furnace, this results in a temperature drop at the ends, leaving only a small, truly uniform hot zone in the very center.

A three-zone furnace overcomes this by allowing you to set the end zones to a higher temperature than the center zone. These end zones act as "guard heaters," actively counteracting the natural heat loss.

The result is a significantly larger, more stable, and more precisely uniform temperature profile along the entire length of the furnace, which is critical for processes where every part of a sample must experience the exact same temperature.

Creating Custom Thermal Profiles

Many advanced processes do not require uniformity but instead need a specific temperature gradient. This might involve a controlled heating ramp, a stable hold, and a controlled cooling stage, all within the same process.

With independent control, you can set each zone to a different temperature. For example, you could have the first zone at 400°C, the middle at 800°C, and the final zone at 600°C.

This is essential for applications like chemical vapor deposition (CVD), annealing, and crystal growth, where the thermal profile directly dictates the final material properties.

Enhancing Repeatability and Throughput

By managing a complex thermal process within one self-contained unit, you eliminate the variability and potential contamination that comes from moving a sample between different furnaces for different steps.

This ensures that every run is identical, leading to highly consistent and repeatable results. For research and development, this also allows for higher experimental throughput by running complex profiles without manual intervention or equipment changes.

Understanding the Trade-offs

While powerful, a three-zone furnace is not always the necessary choice. Its sophistication comes with certain considerations.

Increased Complexity and Cost

The presence of three controllers, three sets of thermocouples, and more intricate wiring makes these systems inherently more complex and expensive than their single-zone counterparts.

Programming and Calibration

Achieving a perfectly flat temperature profile or a precise gradient requires more careful setup. The user must properly program the setpoints for each zone, which can take more time and expertise than simply setting a single temperature.

When a Single-Zone Furnace Is Sufficient

For many simple heat treatment processes, such as debinding or basic sintering where a small central hot zone is adequate, the cost and complexity of a three-zone system may be unnecessary. A single-zone furnace remains a reliable and cost-effective workhorse for these tasks.

Making the Right Choice for Your Process

Your choice should be dictated entirely by the demands of your thermal process.

- If your primary focus is maximum temperature uniformity: A three-zone furnace is superior because it actively compensates for heat loss, creating a much larger and more stable hot zone.

- If your primary focus is creating a specific temperature gradient: A three-zone furnace is essential, as it provides the necessary independent control to set different, stable temperatures along the process tube.

- If your primary focus is simple batch heating on a budget: A single-zone furnace is often the more practical and cost-effective choice for less demanding applications.

Ultimately, understanding this distinction empowers you to select the precise tool required to achieve consistent, high-quality results in your thermal processes.

Summary Table:

| Feature | Benefit |

|---|---|

| Independent Zone Control | Enables precise temperature manipulation for uniformity or gradients |

| Guard Heating in End Zones | Compensates for heat loss, expanding the uniform hot zone |

| Custom Thermal Profiles | Supports complex processes like CVD and annealing with stable gradients |

| Enhanced Repeatability | Reduces variability and contamination for consistent experimental outcomes |

| Increased Throughput | Allows complex processes in one unit without manual intervention |

Ready to elevate your thermal processing with precision and reliability? At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace solutions tailored for diverse laboratory needs. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all backed by strong deep customization capabilities to meet your unique experimental requirements. Don't settle for less—contact us today to discuss how our three-zone furnaces can optimize your process control and deliver superior results!

Visual Guide

Related Products

- Split Multi Heating Zone Rotary Tube Furnace Rotating Tube Furnace

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

People Also Ask

- What types of materials can be processed in a rotary tube furnace? Discover Ideal Materials for High-Temp Processing

- How do rotary tube furnaces achieve precise temperature control? Master Uniform Heating for Dynamic Processes

- What is the purpose of the rotation mechanism in a rotary tube furnace? Achieve Uniform Heating and Enhanced Process Control

- What are the key components of a rotary tube furnace? Essential Parts for Uniform Heating

- What are the main structural components of a rotary furnace? Explore Key Parts for Efficient Material Processing