At its core, a vacuum tube furnace operates by isolating a material inside a sealed tube, removing the air to create a vacuum or replacing it with a specific gas, and then heating it with extreme precision. This process allows for high-temperature experiments without the risk of the material reacting with oxygen or other atmospheric contaminants.

The crucial insight is that a vacuum tube furnace isn't just a heater; it's an environment controller. Its primary purpose is to remove the reactive atmosphere (air) so that the heat treatment affects only the material itself, ensuring purity and predictable results.

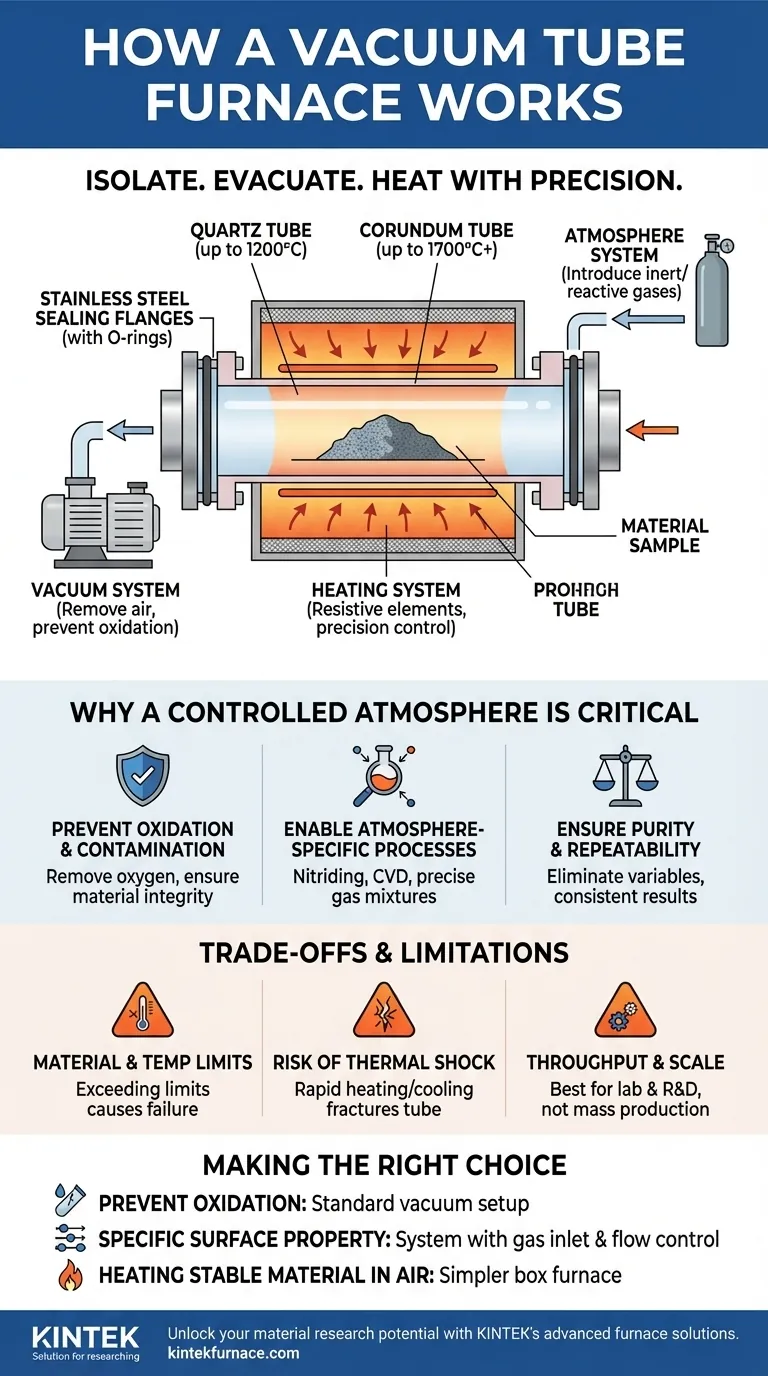

The Core Components of Operation

A vacuum tube furnace integrates several key systems to achieve its precise control over both temperature and atmosphere. Understanding each component reveals how the entire system functions.

The Process Tube: Your Sealed Reaction Chamber

The heart of the furnace is a high-purity tube, typically made of quartz or corundum (alumina). The sample material is placed inside this tube.

Quartz is common for temperatures up to approximately 1200°C, while corundum is used for higher-temperature applications, often up to 1700°C or more.

Sealing Flanges: The Gateway to Control

To create a sealed environment, stainless steel sealing flanges are attached to both ends of the process tube. These flanges are precision-engineered with O-rings to ensure an airtight seal.

These flanges contain ports that are critical for controlling the atmosphere. One port connects to a vacuum system, while another can be used as an inlet for introducing specific gases.

The Vacuum and Atmosphere System

A vacuum pump connects to a flange port to evacuate the air from the tube. Removing oxygen and other reactive gases is the most common reason to use this type of furnace.

Alternatively, after creating a vacuum, an inert gas like argon or nitrogen can be introduced through the gas inlet to conduct the experiment at a specific pressure. This is known as creating a controlled atmosphere.

The Heating System: Precision Thermal Energy

Heating elements, typically resistive wires or silicon carbide rods, surround the outside of the process tube. These elements convert electrical energy into heat.

A sophisticated temperature controller and thermocouple monitor the temperature and regulate power to the heating elements, allowing for stable, uniform, and programmable heating cycles.

Why a Controlled Atmosphere is Critical

Using a vacuum or a specific gas isn't an optional feature; it's central to the furnace's purpose in materials science and research.

Preventing Oxidation and Contamination

At high temperatures, most materials will readily react with oxygen in the air. This process, called oxidation, can fundamentally alter a material's properties or even destroy it.

A vacuum removes the oxygen, preventing these unwanted reactions and ensuring the material's integrity is maintained throughout the heating process.

Enabling Atmosphere-Specific Processes

Some advanced processes require the presence of a specific gas. For example, nitriding involves heating a material in a nitrogen-rich atmosphere to harden its surface.

A tube furnace allows researchers to introduce precise mixtures of reactive or inert gases, enabling experiments that would be impossible in an open-air furnace.

Ensuring Purity and Repeatability

By eliminating the variable of atmospheric composition, a vacuum tube furnace provides a highly repeatable experimental environment. This ensures that results are consistent and directly comparable from one test to another.

Understanding the Trade-offs and Limitations

While powerful, these furnaces are not without their operational constraints. Being aware of them is key to successful and safe experimentation.

Material and Temperature Limits

The choice between a quartz and a corundum tube is dictated by the maximum process temperature. Exceeding a tube's rated temperature can cause it to soften, crack, or fail.

Furthermore, quartz can become brittle over time through a process called devitrification, especially with repeated, rapid temperature cycling.

Risk of Thermal Shock

Both quartz and corundum tubes are susceptible to thermal shock. Heating or cooling the furnace too quickly can create internal stresses in the tube material, causing it to fracture.

Following a controlled, gradual ramp-up and cool-down schedule is essential for prolonging the life of the process tube.

Throughput and Scale

Experimental tube furnaces are designed for precision, not mass production. The size of the tube limits the volume and dimensions of the material that can be processed at one time, making them best suited for laboratory and R&D applications.

Making the Right Choice for Your Experiment

To apply this knowledge, select your furnace configuration based on your primary experimental goal.

- If your primary focus is preventing oxidation: A standard vacuum setup is your ideal choice. The goal is simply to remove the air before heating.

- If your primary focus is creating a specific surface property: You will need a system with a gas inlet and flow controller to introduce a precise reactive atmosphere (e.g., nitrogen for nitriding, methane for carburizing).

- If your primary focus is simply heating a stable material in air: A vacuum tube furnace may be overly complex. A simpler, more economical box or muffle furnace would be more appropriate.

Mastering its principles allows you to move from simply heating a material to precisely engineering its final properties.

Summary Table:

| Component | Function | Key Details |

|---|---|---|

| Process Tube | Sealed reaction chamber | Made of quartz (up to 1200°C) or corundum (up to 1700°C+) |

| Sealing Flanges | Create airtight seal | Stainless steel with O-rings, ports for vacuum and gas inlets |

| Vacuum System | Remove air and contaminants | Uses vacuum pump to evacuate oxygen for purity |

| Atmosphere System | Introduce specific gases | Allows inert gases like argon or reactive gases for processes |

| Heating System | Provide precise thermal energy | Resistive elements with temperature control for uniform heating |

Unlock the full potential of your materials research with KINTEK's advanced high-temperature furnace solutions. Our expertise in R&D and in-house manufacturing ensures you get reliable, customizable equipment tailored to your unique needs. Whether you're working with Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, or CVD/PECVD Systems, we deliver precision and performance to enhance your experimental outcomes. Contact us today to discuss how we can support your laboratory's success!

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

People Also Ask

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- What are the key operational considerations when using a lab tube furnace? Master Temperature, Atmosphere & Safety

- What role does a laboratory tube furnace perform during the carbonization of LCNSs? Achieve 83.8% Efficiency

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab

- How do vertical tube furnaces comply with environmental standards? A Guide to Clean, Efficient Operation