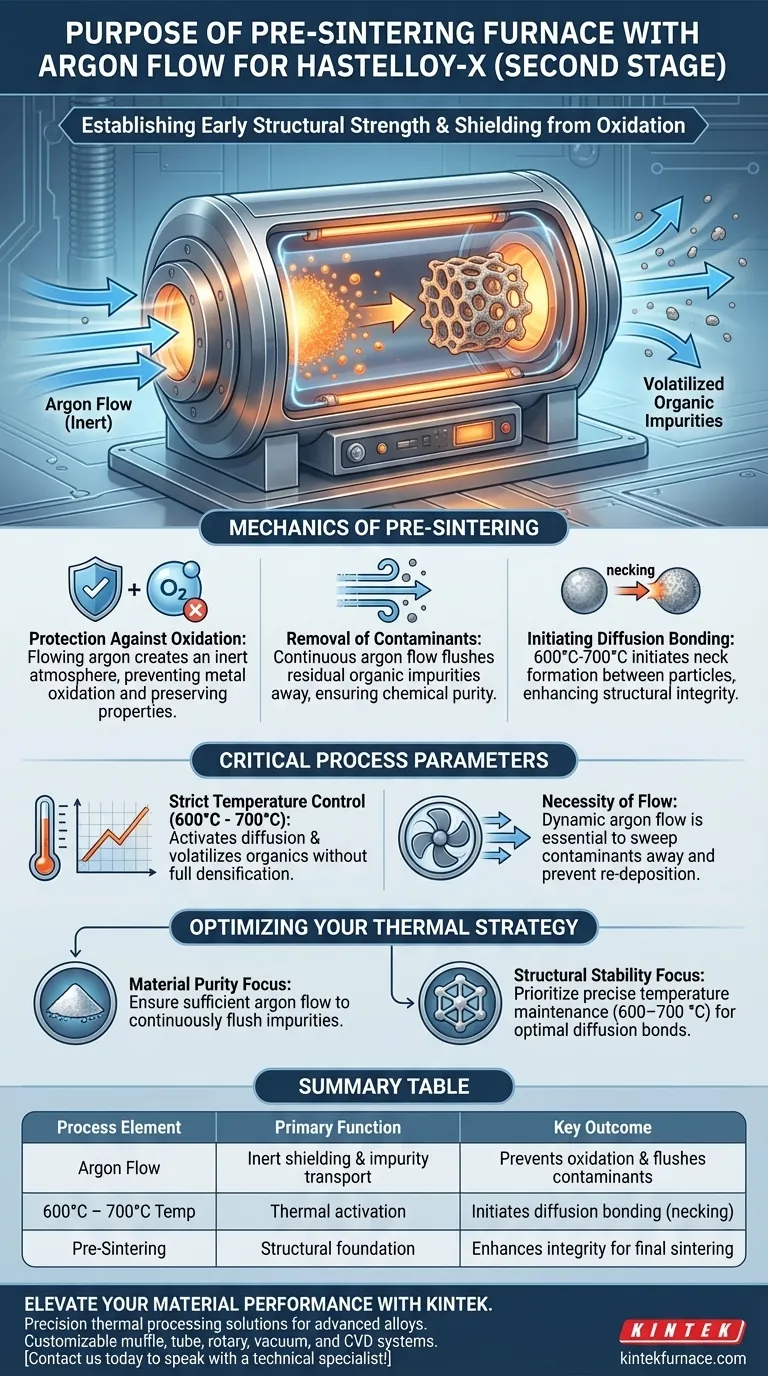

The primary purpose of using a pre-sintering furnace with an argon flow is to shield the Hastelloy-X metal skeleton from oxidation while establishing early structural strength. By maintaining a temperature range of 600 °C to 700 °C, this process facilitates the removal of impurities and initiates the bonding required for the material to survive final processing.

The argon flow serves a dual purpose: it acts as a protective barrier against oxidation and a transport medium for removing residual organic impurities. Simultaneously, the thermal energy creates initial diffusion bonds, transforming loose powder into a cohesive, porous structure ready for high-temperature sintering.

The Mechanics of Pre-Sintering

Protection Against Oxidation

At elevated temperatures, metal powders are highly susceptible to reacting with oxygen. Flowing argon gas provides an inert atmosphere that prevents the Hastelloy-X from oxidizing.

Preserving the metal surface in this state is vital. Oxidation at this stage would compromise the material properties and prevent proper consolidation during the final sintering stages.

Removal of Contaminants

The second stage of thermal processing is not just about heating; it is about cleaning. The process is designed to further remove residual organic impurities left over from previous processing steps.

The continuous flow of argon helps flush these volatile impurities away from the metal skeleton. This ensures the final material is chemically pure and free of carbonaceous defects.

Initiating Diffusion Bonding

The most critical structural change occurs at the particle level. Between 600 °C and 700 °C, the process initiates diffusion bonds between the Hastelloy-X powder particles.

This is not full densification, but rather the formation of "necks" between particles. This significantly enhances the structural integrity of the porous material, ensuring it is strong enough to handle the stress of final high-temperature sintering.

Critical Process Parameters

Strict Temperature Control

The effectiveness of this stage relies on maintaining the temperature strictly between 600 °C and 700 °C.

This specific window provides enough energy to activate diffusion bonding and volatilize organics. However, it avoids the higher temperatures reserved for the final densification phase, which requires a fully clean and stabilized skeleton.

The Necessity of Flow

The argon cannot simply be static; it must be flowing.

A static atmosphere might protect against oxidation, but it would fail to effectively sweep away the organic impurities releasing from the metal. The flow carries contaminants out of the furnace, preventing re-deposition on the Hastelloy-X surface.

Optimizing Your Thermal Strategy

If your primary focus is Material Purity: Ensure the argon flow rate is sufficient to continuously flush out volatilized organic impurities before they can react with the metal.

If your primary focus is Structural Stability: Prioritize precise temperature maintenance within the 600–700 °C range to maximize the formation of diffusion bonds without prematurely densifying the part.

This pre-sintering stage is the foundational step that ensures your Hastelloy-X components are both chemically clean and physically robust enough for final production.

Summary Table:

| Process Element | Primary Function | Key Outcome |

|---|---|---|

| Argon Flow | Inert shielding & impurity transport | Prevents oxidation & flushes contaminants |

| 600°C - 700°C Temp | Thermal activation | Initiates diffusion bonding (necking) |

| Pre-Sintering | Structural foundation | Enhances integrity for final sintering |

Elevate Your Material Performance with KINTEK

Precision is non-negotiable in the thermal processing of advanced alloys like Hastelloy-X. Backed by expert R&D and world-class manufacturing, KINTEK provides high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems designed to meet your most rigorous specifications.

Whether you need strictly controlled argon atmospheres or custom high-temperature solutions, our laboratory furnaces are fully customizable to ensure your materials achieve maximum purity and structural strength.

Ready to optimize your sintering workflow? Contact us today to speak with a technical specialist!

Visual Guide

References

- Aleksandra Bętkowska, Wojciech Polkowski. Microstructure and mechanical properties of highly porous Hastelloy-X nickel superalloy produced by a space holder approach. DOI: 10.1038/s41598-024-84321-3

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What industries commonly use retort furnaces and for what purposes? Unlock High-Purity Thermal Processing

- What is a box type annealing atmosphere furnace? Master Controlled Heat Treatment for Superior Materials

- What is the composition of a typical endothermic atmosphere used for heat treating steel? Optimize Your Steel Heat Treatment Process

- Why is an XHV equivalent protective atmosphere required for heating uncoated steel? Achieve Scale-Free Surface Purity

- What is the primary function of the vacuum atmosphere in diamond tool sintering? Prevent Oxidation & Enhance Bonding

- How does the box type annealing atmosphere furnace ensure accurate temperature control? Discover Precision Heating Solutions

- Why is it important to isolate the working space in an atmosphere furnace from outside air? Ensure Process Control and Safety

- What are the advantages of an atmosphere box furnace in ceramic material preparation? Unlock Precise Control for Superior Ceramics