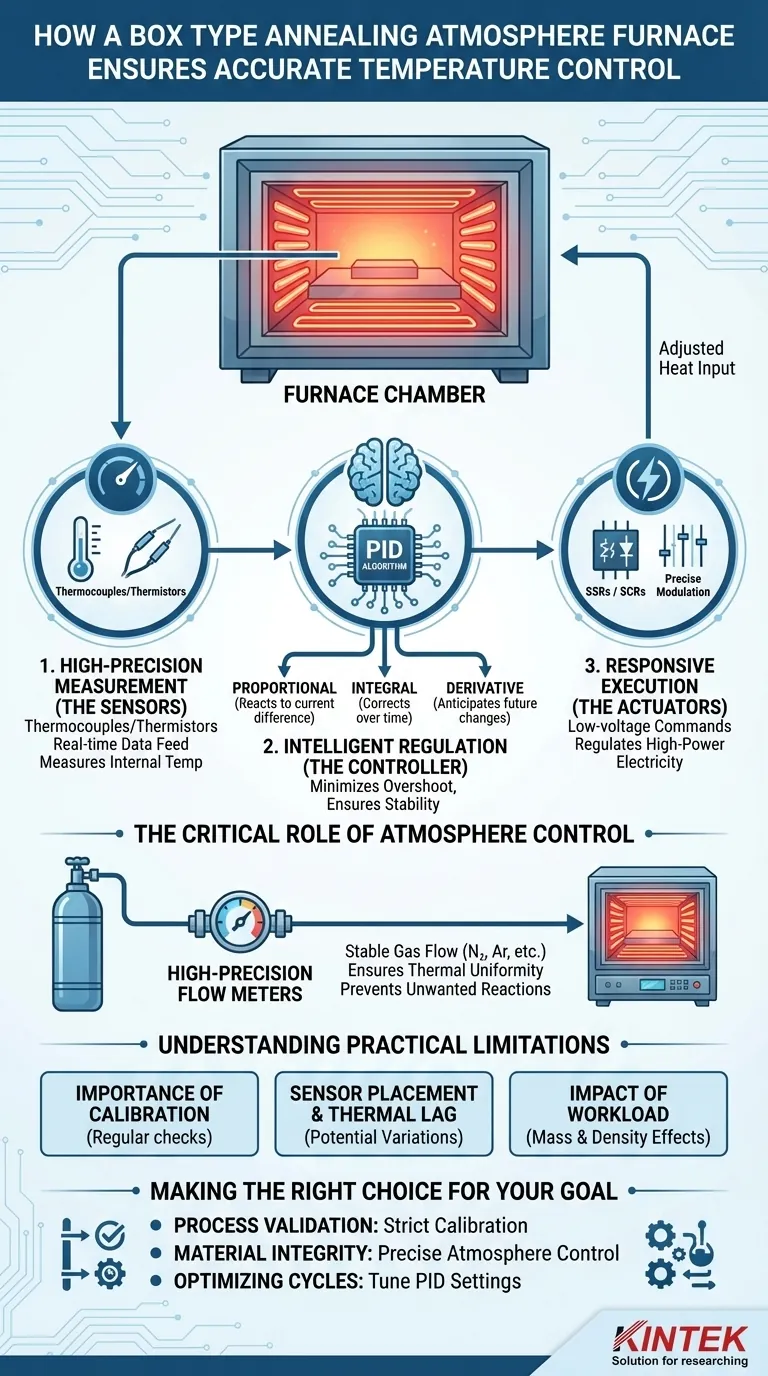

At its core, a box type annealing atmosphere furnace achieves accurate temperature control through a sophisticated closed-loop feedback system. This system constantly measures the internal temperature with high-precision sensors, uses an intelligent controller with a PID algorithm to calculate necessary adjustments, and deploys actuators to precisely modulate the power supplied to the heating elements.

Achieving precise and repeatable thermal outcomes isn't about a single component, but the seamless integration of three key functions: real-time measurement, intelligent regulation, and responsive power execution. This ensures the furnace temperature doesn't just reach the setpoint, but holds it with exceptional stability.

The Core Components of Temperature Control

A modern atmosphere furnace operates like a highly disciplined team, with each component performing a specific task to maintain thermal accuracy. The system is comprised of sensors, a controller, and actuators.

High-Precision Measurement (The Sensors)

The entire control process begins with an accurate measurement. The furnace relies on industrial-grade temperature sensors, typically high-precision thermocouples or thermistors, placed strategically within the heating chamber.

These devices convert thermal energy into an electrical signal, providing a constant, real-time data feed of the furnace's internal conditions. The quality and placement of this sensor are the foundation of accurate control.

Intelligent Regulation (The Controller)

The signal from the sensor is sent to an intelligent temperature controller, which acts as the brain of the operation. This controller uses a PID (Proportional-Integral-Derivative) algorithm to make decisions.

Think of PID control like an expert driver maintaining a constant speed.

- Proportional: Reacts to the current difference between your set temperature and the actual temperature.

- Integral: Corrects for small, steady-state errors over time, ensuring you eventually hit the exact target.

- Derivative: Anticipates future changes by reacting to the rate of temperature change, preventing overshoot or undershoot.

This algorithm allows the furnace to ramp up to temperature quickly, minimize overshoot, and hold the target temperature with minimal fluctuation.

Responsive Execution (The Actuators)

The controller's decisions are meaningless without a way to act on them. This is the job of the actuators, which are typically solid-state relays (SSRs) or thyristor regulators (SCRs).

These components receive the low-voltage command signals from the PID controller and precisely modulate the high-power electricity flowing to the furnace's heating elements. They can make micro-adjustments many times per second, delivering just enough energy to counteract heat loss and maintain stability.

The Critical Role of Atmosphere Control

In an atmosphere furnace, temperature control does not work in isolation. The composition and flow of the internal atmosphere are directly linked to thermal performance.

Ensuring Thermal Uniformity

A stable and consistent flow of atmosphere gas (such as nitrogen or argon) is managed by high-precision gas flow meters. This controlled flow is essential for distributing heat evenly throughout the chamber, preventing hot or cold spots that could compromise the annealing process.

Preventing Unwanted Chemical Reactions

The primary purpose of an atmosphere furnace is to heat a material without causing oxidation or other unwanted chemical reactions. By precisely controlling the gas type, concentration, and flow rate, the system creates a stable, inert, or reactive environment. This atmospheric stability is a prerequisite for uniform heat transfer and predictable temperature control.

Understanding the Practical Limitations

Even the most advanced system has practical considerations that impact its real-world accuracy. Understanding these is key to mastering the process.

The Importance of Calibration

A temperature control system is only as accurate as its last calibration. Over time, sensors can drift. Regular calibration of the thermocouples against a certified standard is critical maintenance for ensuring the temperature displayed is the temperature you are actually getting.

Sensor Placement and Thermal Lag

The sensor measures the temperature at a single point. Depending on the size of the furnace chamber and the density of the workload, there can be slight temperature variations in other areas. This is known as thermal lag, and understanding its potential impact is vital for large or sensitive parts.

Impact of the Workload

The mass, density, and arrangement of the parts being annealed (the "load") significantly affect the furnace's thermal dynamics. A large, dense load absorbs a great deal of energy and requires a properly tuned PID controller to heat evenly without overshooting the target temperature.

Making the Right Choice for Your Goal

Your operational focus will determine which aspects of the control system demand the most attention.

- If your primary focus is process validation and quality control: Prioritize a strict and documented schedule for sensor calibration.

- If your primary focus is material integrity (e.g., preventing oxidation): Ensure the atmosphere control system (flow meters and gas regulators) is as precise as the temperature controller.

- If your primary focus is optimizing cycle times with different loads: Invest time in learning to properly tune the PID settings to match your specific thermal requirements, preventing overshoot and reducing stabilization time.

By understanding this integrated system of measurement, control, and execution, you can ensure your annealing process is not just accurate, but consistently reliable.

Summary Table:

| Component | Function | Key Features |

|---|---|---|

| Sensors | Measure temperature | High-precision thermocouples/thermistors, real-time data |

| Controller | Regulate temperature | PID algorithm, minimizes overshoot, ensures stability |

| Actuators | Execute power adjustments | Solid-state relays (SSRs), precise energy modulation |

| Atmosphere Control | Manage gas flow | High-precision flow meters, ensures thermal uniformity |

Achieve unparalleled precision in your annealing processes with KINTEK! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnace solutions tailored for diverse laboratories. Our product line includes Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, all supported by strong deep customization capabilities to meet your unique experimental needs. Contact us today to discuss how our expertise can enhance your lab's efficiency and reliability!

Visual Guide

Related Products

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- Mesh Belt Controlled Atmosphere Furnace Inert Nitrogen Atmosphere Furnace

- Controlled Inert Nitrogen Hydrogen Atmosphere Furnace

People Also Ask

- What does inert mean in furnace atmospheres? Protect materials from oxidation with inert gases.

- How does a chemically inert atmosphere function in a furnace? Prevent Oxidation and Ensure Material Purity

- What are the benefits of inert atmosphere heat treating? Prevent Oxidation and Preserve Material Integrity

- What are the environmental benefits of using inert gases in furnaces? Reduce Waste and Emissions for a Greener Process

- How does nitrogen atmosphere heat treatment improve surface strengthening? Enhance Durability and Performance