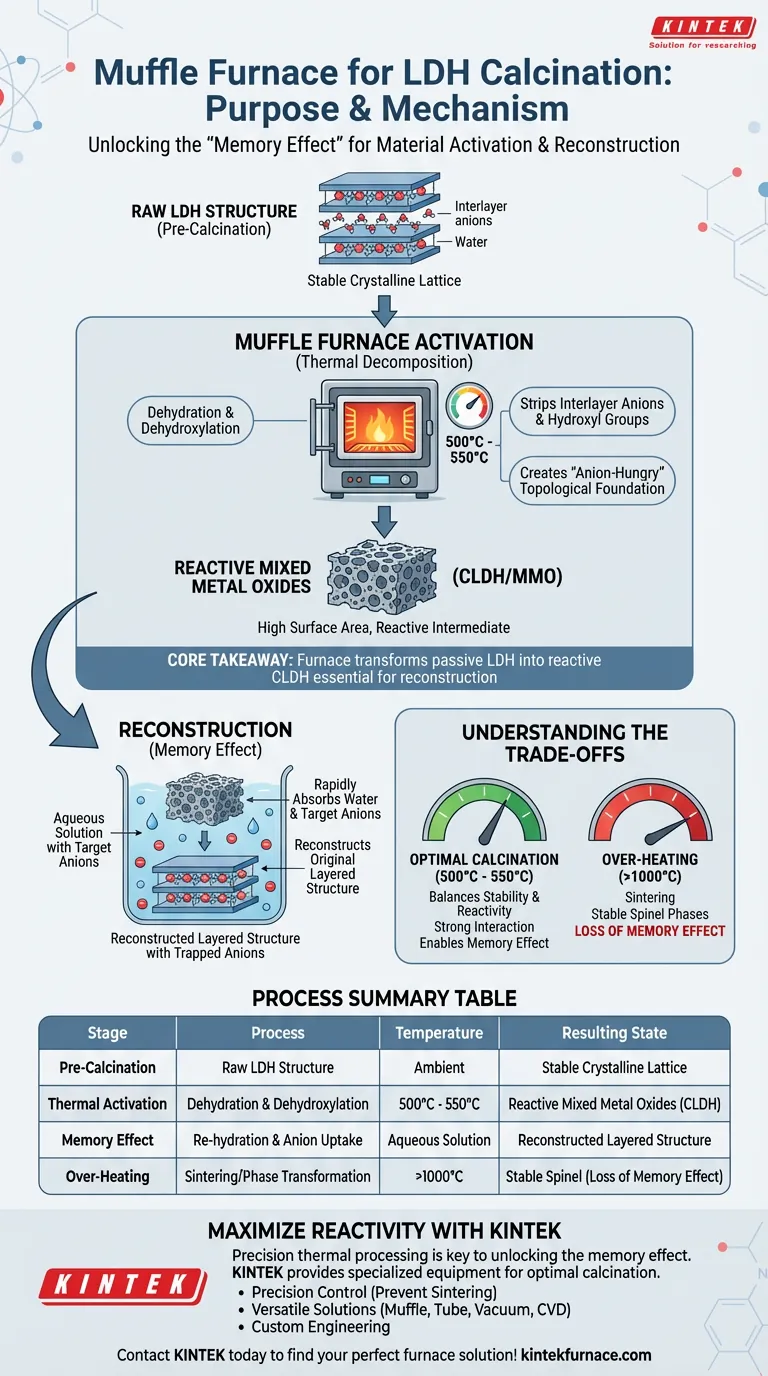

The primary purpose of using a muffle furnace in this context is to thermally decompose the Layered Double Hydroxide (LDH) structure into a highly reactive intermediate state, known as Mixed Metal Oxides (MMO).

This process involves subjecting the LDH to temperatures around 500°C to 550°C, which strips away interlayer anions and hydroxyl groups. This creates a disordered "topological foundation" that enables the material to re-absorb specific anions from a solution and reconstruct its original layered structure through a phenomenon known as the memory effect.

Core Takeaway The muffle furnace is the activation tool that transforms stable LDH into reactive Calcined Layered Double Hydroxide (CLDH). This thermal decomposition significantly increases surface area and creates an "anion-hungry" oxide lattice essential for subsequent reconstruction and adsorption applications.

The Mechanism of Thermal Decomposition

Removing Structural Components

The muffle furnace provides a stable thermal environment necessary to drive the dehydration and dehydroxylation of the LDH material.

As the temperature rises, typically to 550°C, the furnace heat forces the removal of physical water, interlayer water, and eventually the hydroxyl groups bonded to the metal layers. Simultaneously, the heat decomposes the volatile interlayer anions (such as carbonates).

Formation of Mixed Metal Oxides (MMO)

This thermal treatment collapses the ordered laminate structure of the LDH.

The result is a transformation into Calcined Layered Double Hydroxide (CLDH), also referred to as Mixed Metal Oxides. Unlike the original crystalline LDH, this new phase is highly disordered and amorphous, composed of well-dispersed metal oxides (e.g., CuZnAl oxides).

Enabling the Memory Effect

Creating a Topological Foundation

The critical value of this calcination is that it does not destroy the metal arrangement entirely; rather, it creates a specific "topological foundation."

This oxide backbone retains the potential to revert to its original form. Because the oxides are chemically unstable compared to the layered hydroxide form, they possess a strong thermodynamic drive to re-hydrate and re-anionize.

Restoring the Layered Structure

When this calcined intermediate is introduced to a specific aqueous solution, it rapidly absorbs water and target anions to fill the vacancies created by the furnace.

This allows the material to reconstruct the original LDH structure. This "memory effect" is the primary mechanism used to trap specific pollutants or target anions inside the reformed layers, significantly enhancing adsorption capacity compared to raw LDH.

Understanding the Trade-offs

Temperature Sensitivity

While high heat is necessary, precise temperature control is critical.

If the temperature is too low, the anions are not fully removed, and the active sites are not generated. However, if the temperature is excessive (e.g., approaching 1000°C as used in ceramic synthesis), the oxides may sinter into stable spinel phases. These stable phases lose the memory effect and cannot reconstruct into the layered structure.

Structural Stability vs. Reactivity

The calcination process aims to balance stability with reactivity.

Proper calcination ensures a strong interaction between active metals and the carrier, improving leaching resistance. However, the resulting MMO is hygroscopic and must be handled carefully to prevent premature reconstruction with atmospheric moisture before the intended application.

Making the Right Choice for Your Goal

The use of a muffle furnace is a preparatory step that dictates the efficiency of your final application.

- If your primary focus is Environmental Remediation (Adsorption): Ensure your calcination completely removes interlayer anions to maximize the material's capacity to uptake pollutants during reconstruction.

- If your primary focus is Catalyst Stability: Use the furnace to induce strong metal-carrier interactions, ensuring the active metals resist leaching during liquid-phase reactions.

Ultimately, the muffle furnace converts a passive layered clay into an active chemical sponge capable of selective reconstruction.

Summary Table:

| Stage | Process | Temperature | Resulting State |

|---|---|---|---|

| Pre-Calcination | Raw LDH Structure | Ambient | Stable Crystalline Lattice |

| Thermal Activation | Dehydration & Dehydroxylation | 500°C - 550°C | Reactive Mixed Metal Oxides (CLDH) |

| Memory Effect | Re-hydration & Anion Uptake | Aqueous Solution | Reconstructed Layered Structure |

| Over-Heating | Sintering/Phase Transformation | >1000°C | Stable Spinel (Loss of Memory Effect) |

Maximize Your Material Reactivity with KINTEK

Precision thermal processing is the key to unlocking the 'memory effect' in LDH reconstruction. At KINTEK, we provide the specialized equipment needed to maintain the exact temperature profiles required for optimal calcination.

Our Advantage to You:

- Precision Control: Prevent sintering and spinel formation with advanced PID controllers.

- Versatile Solutions: Choose from Muffle, Tube, Vacuum, and CVD systems tailored for laboratory and industrial R&D.

- Custom Engineering: Our high-temperature furnaces are customizable to your unique material synthesis needs.

Whether you are focusing on environmental remediation or catalyst stability, our expert R&D and manufacturing team is ready to support your goals. Contact KINTEK today to find your perfect furnace solution!

Visual Guide

References

- Ioana M. Popa, Luca Artiglia. Exploiting the LDH Memory Effect in the Carbon Dioxide to Methanol Conversion. DOI: 10.1002/adfm.202502812

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the common uses of box type electric furnaces in heat treatment processes? Achieve Precise Material Property Control

- How is a muffle furnace utilized in the post-treatment for B-doped SiC nanowires? Ensure High Purity & Integrity

- What is a hydrogen muffle furnace and how does it work? Precision Heating with Hydrogen for Oxide-Free Results

- Why is a muffle furnace essential for Sn:ZnO nanopowders? Achieve Perfect Crystal Structure and Purity

- What role does a high-temperature box resistance furnace play in sintering? Mastering Electrolyte Tube Densification

- What role does a muffle furnace play in silver film transformation? Master Nanoparticle Self-Assembly with Precision

- How are muffle furnaces used in the glass industry? Precision Heating for Quality Control and Tempering

- How does the position of gas inlets in a muffle furnace affect the temperature distribution? Master Thermal Uniformity