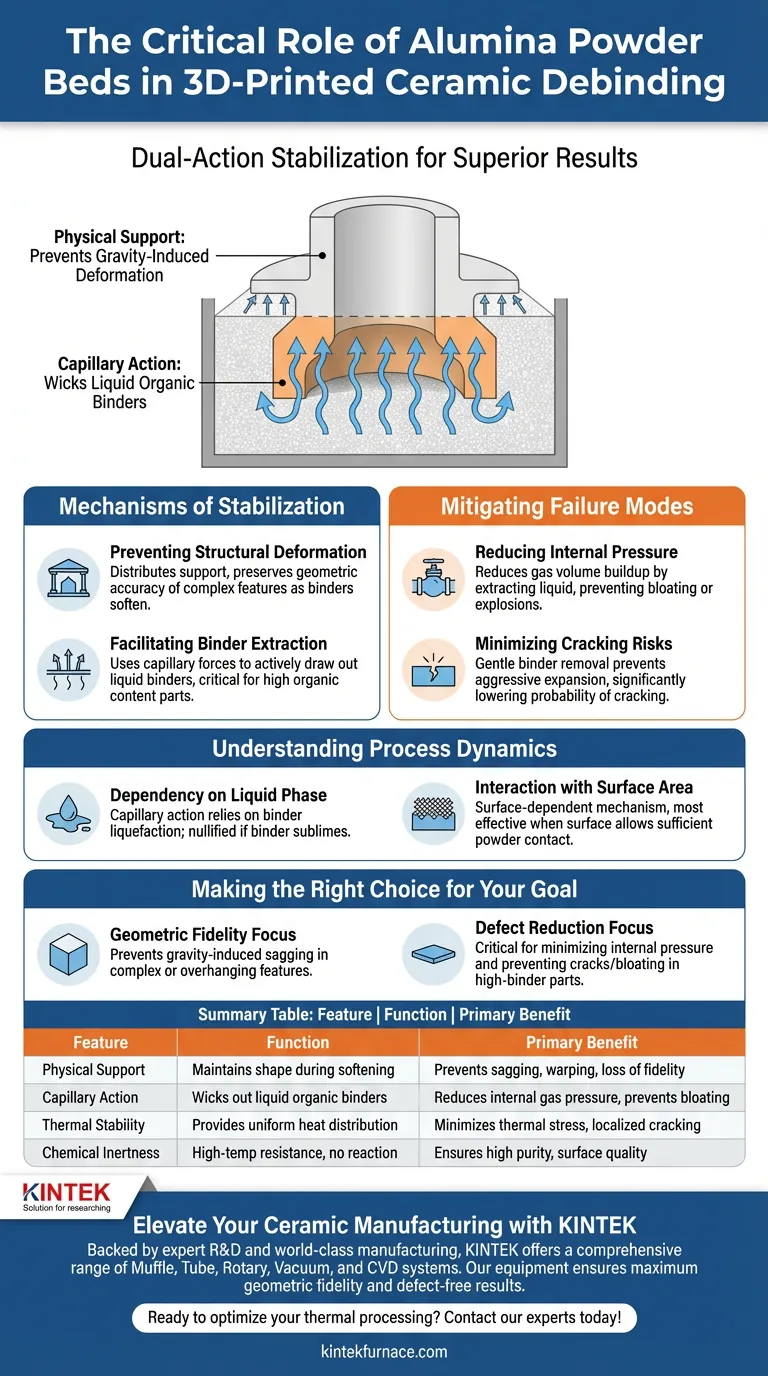

The purpose of an alumina powder bed is to serve as a dual-action stabilizing medium that ensures the survival of 3D-printed ceramic parts during the critical thermal debinding phase. It provides essential physical support to maintain complex geometries while simultaneously utilizing capillary forces to actively extract liquid organic binders.

By acting as both a scaffold and a wick, the alumina powder bed mitigates the two most common causes of part failure: structural collapse due to gravity and internal fractures caused by gas pressure buildup.

Mechanisms of Stabilization

To understand why the alumina bed is necessary, one must look at the physical state of a "green" (un-sintered) ceramic part. As temperatures rise, the binders softening the part can lead to distortion.

Preventing Structural Deformation

During the early stages of thermal debinding, the organic binders within the ceramic part often soften or liquefy before they are removed.

Without external support, complex 3D-printed parts are highly susceptible to sagging or warping under their own weight.

The alumina powder bed packs around the part, providing a distributed physical support system. This preserves the dimensional accuracy of intricate features that would otherwise deform.

Facilitating Binder Extraction

Beyond simple support, the powder bed plays an active role in the chemical process.

It utilizes capillary forces to draw liquid organic binders out of the ceramic body.

This "wicking" effect is critical for parts with high organic content, as it creates a pathway for binders to exit the part gently rather than boiling off violently inside the structure.

Mitigating Failure Modes

The transition from a binder-filled part to a porous ceramic structure is the most perilous step in manufacturing. The alumina bed directly addresses the risks of internal stress.

Reducing Internal Pressure

When binders degrade into gas within a part, they create internal pressure. If this pressure builds faster than the gas can escape, the part will bloat or explode.

By extracting the binder in its liquid state via capillary action, the powder bed significantly reduces the volume of material that must eventually turn into gas.

Minimizing Cracking Risks

The gentle removal of binders via wicking prevents the aggressive expansion associated with rapid gas evolution.

This process protects the internal structure of the part, significantly lowering the probability of cracking or bloating.

Understanding the Process Dynamics

While the alumina powder bed is a powerful tool, it relies on specific physical interactions to function correctly.

Dependency on Liquid Phase

The efficacy of the capillary action depends entirely on the binder entering a liquid phase.

If a binder system sublimes (turns directly to gas) without liquefying, the wicking advantage of the alumina bed is nullified, leaving it only as a physical support.

Interaction with Surface Area

The capillary extraction is a surface-dependent mechanism.

This means the technique is particularly effective for parts where the surface area allows for sufficient contact with the powder to facilitate the flow of liquid binder.

Making the Right Choice for Your Goal

The use of an alumina powder bed is not merely about holding a part in place; it is a strategy for managing internal mass transport.

- If your primary focus is Geometric Fidelity: The powder bed is essential to prevent gravity-induced deformation in complex or overhanging features as the binder softens.

- If your primary focus is Defect Reduction: The capillary action is critical for minimizing internal pressure, preventing the cracks and bloating associated with high-binder content parts.

An alumina powder bed transforms debinding from a high-risk thermal event into a controlled, gradual extraction process.

Summary Table:

| Feature | Function in Debinding | Primary Benefit |

|---|---|---|

| Physical Support | Maintains shape of green parts during binder softening | Prevents sagging, warping, and loss of geometric fidelity |

| Capillary Action | Wicks out liquid organic binders through surface contact | Reduces internal gas pressure and prevents bloating |

| Thermal Stability | Provides uniform heat distribution around the part | Minimizes thermal stress and localized cracking |

| Chemical Inertness | High-temperature resistance without reacting to ceramics | Ensures high purity and surface quality of the final part |

Elevate Your Ceramic Manufacturing with KINTEK

Precise debinding is the foundation of high-performance ceramics. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Muffle, Tube, Rotary, Vacuum, and CVD systems, as well as other lab high-temperature furnaces. Whether you need to manage complex wicking processes or require customizable systems for unique material needs, our equipment ensures maximum geometric fidelity and defect-free results.

Ready to optimize your thermal processing? Contact our experts today to find the perfect furnace solution for your laboratory or production line!

Visual Guide

References

- Eveline Zschippang, Anne‐Kathrin Wolfrum. Sintering of Si <sub>3</sub> N <sub>4</sub> –SiC–MoSi <sub>2</sub> composites additively manufactured by Multi Material Jetting. DOI: 10.1111/ijac.14715

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Multi Heating Zones CVD Tube Furnace Machine for Chemical Vapor Deposition Equipment

- Electric Rotary Kiln Small Rotary Furnace Biomass Pyrolysis Plant Rotating Furnace

- Molybdenum Disilicide MoSi2 Thermal Heating Elements for Electric Furnace

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

People Also Ask

- How do dense-walled crucibles function during the high-temperature melting of bismuth-lead-borosilicate glass?

- What is the importance of high-purity Argon flow control equipment? Ensure Purity in Pulsed Irradiation Synthesis

- What role do Niobium ampoules play in synthesis? Secure High-Temp Protection for Sensitive Germanium Compounds

- How can the temperature resistance of alumina ceramic furnace tubes be assessed? Ensure Long-Term Reliability in Your Lab

- Why is the integration of a K-type thermocouple and a data logger necessary for Vanadis 60 steel? Unlock Precision.

- What is the significance of high-precision mass flow controllers in testing NiFe2O4? Ensure Data Integrity

- How do industrial sealing clamps and O-ring systems ensure process repeatability? Achieve Consistent Sintering Quality

- What are the main reasons for the alumina furnace tube being prone to breaking? Prevent Costly Failures with Expert Tips