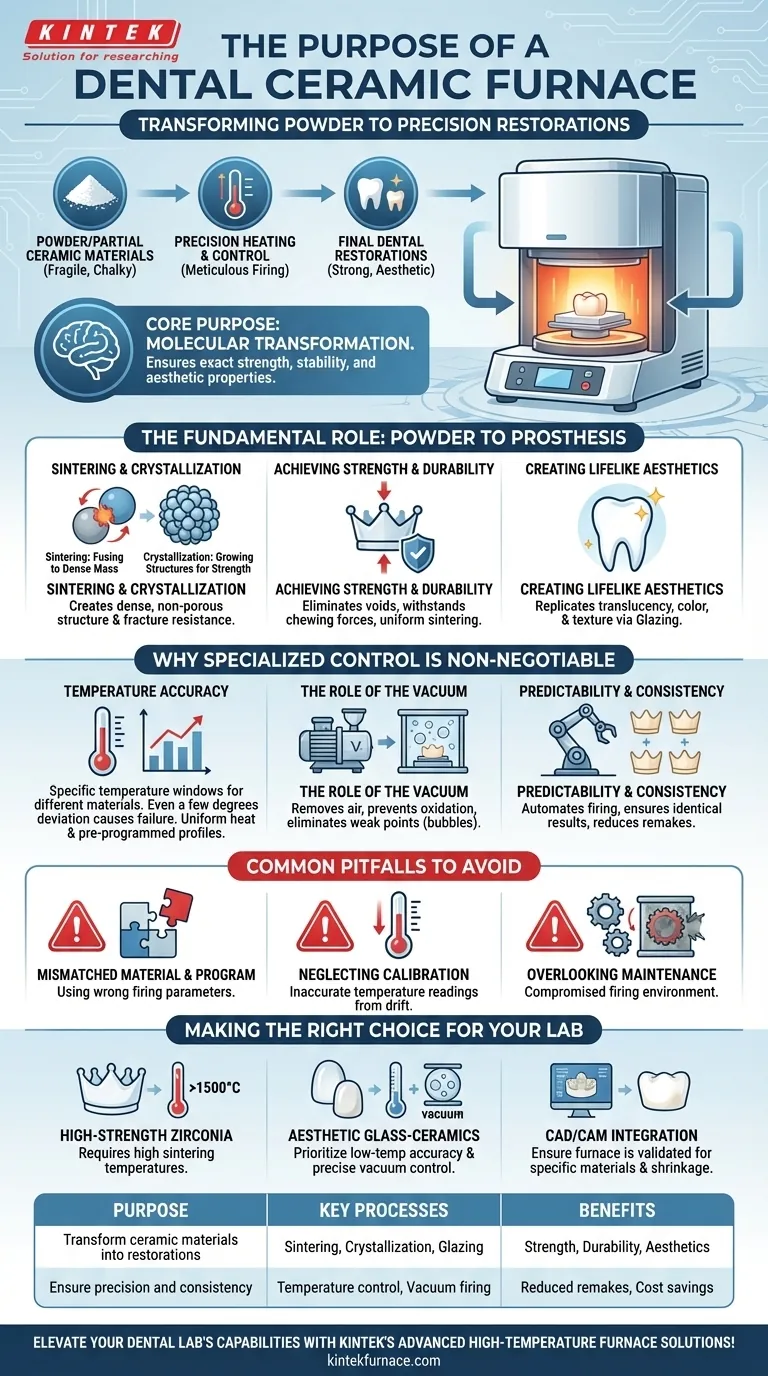

At its core, a dental ceramic furnace is a high-precision oven used in dental laboratories to transform powdered or partially processed ceramic materials into strong, aesthetically pleasing dental restorations. This specialized equipment meticulously controls heat to fire substances like porcelain, creating durable and lifelike crowns, bridges, and veneers that can be permanently placed in a patient's mouth.

The true purpose of a dental furnace is not just to heat material, but to precisely manage a molecular transformation. It ensures that a final restoration possesses the exact strength, stability, and aesthetic properties required to function and look like a natural tooth.

The Fundamental Role: From Powder to Prosthesis

A dental furnace is the final, critical step in the fabrication of many all-ceramic restorations. It takes a fragile, chalky material and turns it into a dense, biocompatible structure.

What is Sintering and Crystallization?

Sintering is the core process. Imagine pressing sand particles together and heating them until they fuse into a solid piece of glass without ever melting completely. A dental furnace does this with ceramic particles, creating a dense, non-porous mass.

For some materials, this is followed by crystallization, where the heating cycle is managed to grow specific crystal structures within the ceramic, dramatically increasing its strength and fracture resistance.

Achieving Strength and Durability

The primary goal of firing is to create a restoration that can withstand the immense forces of chewing. An improperly fired crown will be porous and weak, leading to premature fracture and failure.

The furnace's programmed heating and cooling cycles are designed to eliminate voids and ensure complete, uniform sintering throughout the restoration, resulting in maximum structural integrity.

Creating Lifelike Aesthetics

A natural tooth has a complex translucency, color, and surface texture. A dental furnace helps replicate this through glazing cycles.

A final, lower-temperature firing with a thin layer of glass glaze creates a smooth, stain-resistant, and natural-looking luster on the restoration's surface, mimicking the enamel of a real tooth.

Why Specialized Control is Non-Negotiable

A standard oven cannot be used for this process. Dental furnaces are precision instruments where every degree and minute matters.

The Importance of Temperature Accuracy

Different ceramic materials, like Zirconia or Lithium Disilicate, have very specific and narrow temperature windows for sintering and crystallization. A deviation of even a few degrees can result in a complete failure.

The furnace must provide uniform heat and follow a pre-programmed temperature profile—including the rate of heating, the holding time at peak temperature, and the cooling rate—with absolute precision.

The Role of the Vacuum

Many firing cycles are performed under a vacuum. The furnace's integrated vacuum pump removes air from the firing chamber.

This prevents oxygen from reacting with the ceramic and, more importantly, eliminates the risk of trapping air bubbles within the material, which would create significant weak points in the final restoration.

Predictability and Consistency

By automating the firing cycle, a dental furnace removes human error and ensures that every restoration of the same type is processed identically. This consistency is crucial for reducing remakes, saving both time and material costs for the dental laboratory.

Common Pitfalls to Avoid

Even with advanced equipment, the quality of the final product depends on proper use and understanding of the technology.

Mismatched Material and Program

Using a firing program designed for one type of ceramic on a different material is a common and costly mistake. Each manufacturer provides specific firing parameters that must be followed exactly.

Neglecting Calibration

Over time, the furnace's thermocouple (its internal thermometer) can drift, leading to inaccurate temperature readings. Regular calibration is essential to ensure the furnace is actually reaching the temperatures displayed, guaranteeing consistent and successful results.

Overlooking Furnace Maintenance

The muffle (heating chamber) and vacuum pump are critical components that require routine maintenance. Contamination or wear and tear can compromise the firing environment and lead to failed restorations.

Making the Right Choice for Your Lab

The ideal furnace depends entirely on the type of restorations your laboratory produces.

- If your primary focus is high-strength zirconia substructures: You need a furnace capable of reaching the very high sintering temperatures required for zirconia (often above 1500°C).

- If your primary focus is highly aesthetic glass-ceramics (e.g., veneers): Prioritize a porcelain furnace with exceptional low-temperature accuracy, precise vacuum control, and reliable glazing programs.

- If your primary focus is integrating with a CAD/CAM workflow: Ensure the furnace is validated for the specific materials you mill, as the "sintering shrinkage" must be perfectly predictable for the restoration to fit.

Ultimately, the dental furnace is the cornerstone of quality control, turning digital designs and raw materials into functional, beautiful restorations.

Summary Table:

| Purpose | Key Processes | Benefits |

|---|---|---|

| Transform ceramic materials into restorations | Sintering, Crystallization, Glazing | Strength, Durability, Aesthetics |

| Ensure precision and consistency | Temperature control, Vacuum firing | Reduced remakes, Cost savings |

Elevate your dental lab's capabilities with KINTEK's advanced high-temperature furnace solutions! Leveraging exceptional R&D and in-house manufacturing, we provide diverse laboratories with tailored dental ceramic furnaces, including Muffle, Tube, Rotary, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems. Our strong deep customization capability precisely meets your unique experimental needs, ensuring superior performance for restorations like crowns, bridges, and veneers. Contact us today to discuss how our solutions can enhance your workflow and deliver consistent, high-quality results!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Laboratory Muffle Oven Furnace with Bottom Lifting

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

People Also Ask

- Why is precise temperature control important in dental sintering furnaces? Ensure Strong, Aesthetic Dental Restorations

- What are some common mistakes when operating dental sintering furnaces? Avoid Costly Errors for Perfect Zirconia Restorations

- Why is calibration important for dental sintering furnaces? Ensure Perfect Restorations and Avoid Costly Failures

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations