The primary role of a vacuum vertical tube furnace is to create a precisely controlled environment with two critical, simultaneous conditions: the extreme heat needed to drive the carbothermal reduction of magnesium oxide, and the low pressure required to make the reaction thermodynamically favorable at a viable temperature. This specialized furnace then uses its vertical design to separate and collect the pure magnesium vapor as a solid metal.

The furnace is not merely a high-temperature oven. It is an engineered system that manipulates thermodynamics and physical states to efficiently produce magnesium vapor and then physically separate it from other reaction byproducts, ensuring high yield and purity.

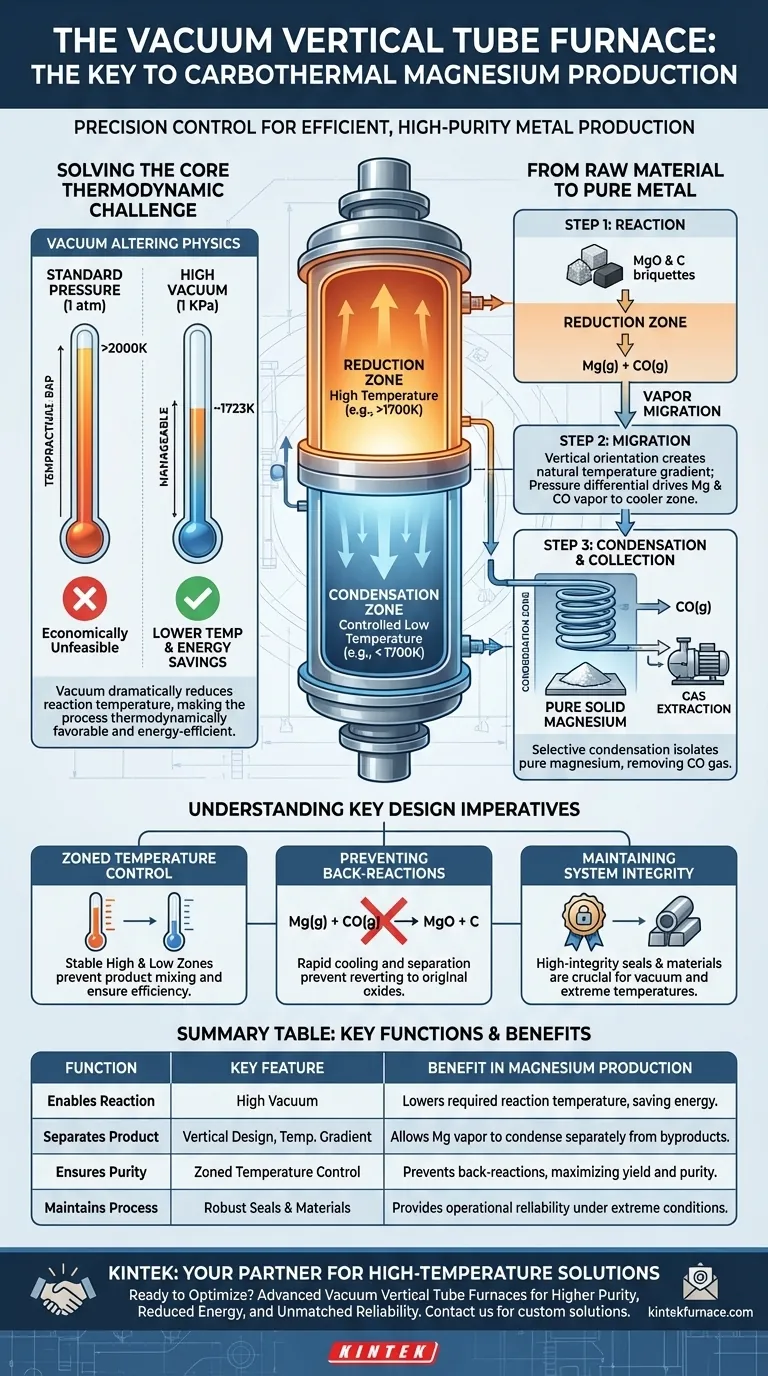

Solving the Core Thermodynamic Challenge

The carbothermal reduction of magnesium is a fundamentally difficult process at atmospheric pressure. The vacuum furnace is the key that unlocks its viability by altering the underlying physics of the reaction.

The Problem at Standard Pressure

Under normal atmospheric conditions, reducing magnesium oxide (MgO) with carbon requires an impractically high temperature. This massive energy requirement makes the process economically and technically unfeasible for large-scale production.

How Vacuum Changes the Equation

By operating under a high vacuum (e.g., 1 KPa), the furnace dramatically lowers the thermodynamic temperature required for the reaction. Reducing the ambient pressure makes it easier for the magnesium to turn into a vapor, effectively pulling the reaction forward at a lower temperature, such as 1723 K. This leads to substantial energy savings.

From Raw Material to Pure Metal

Beyond enabling the initial reaction, the furnace's design is critical for isolating the final product. This is achieved through a carefully managed temperature gradient from the top to the bottom of the vertical tube.

Step 1: Generating Magnesium Vapor

In the furnace's high-temperature reduction zone, briquettes of magnesium oxide and a carbon-based reducing agent are heated. This induces the reaction, producing magnesium (Mg) and carbon monoxide (CO), both in a gaseous state.

Step 2: The Migration of Vapor

The vertical orientation of the furnace creates a natural temperature gradient. A pressure differential drives the hot magnesium vapor and CO gas mixture from the hotter reduction zone towards a cooler, designated condensation zone.

Step 3: Selective Condensation and Collection

In this cooler zone, the temperature is precisely controlled to be below the condensation point of magnesium but above that of other byproducts. Here, the magnesium vapor nucleates and condenses onto a specialized substrate, forming a deposit of pure, solid metallic magnesium. The carbon monoxide gas, which does not condense, is pumped out by the vacuum system.

Understanding the Key Design Imperatives

The success of this process hinges on the furnace's ability to maintain specific conditions without fail. Any deviation can compromise the yield and purity of the final product.

The Need for Zoned Temperature Control

The entire system relies on having two distinct and independently controlled temperature zones. A stable, high-temperature zone is needed for the reaction, while a stable, cooler zone is essential for efficient condensation. This separation is what prevents the products from mixing or back-reacting.

Preventing Back-Reactions

If magnesium vapor and carbon monoxide cool down together slowly, they can revert back into magnesium oxide and carbon. The furnace's sharp temperature gradient and rapid separation of vapor into the condensation zone are critical for preventing this back-reaction and maximizing the metal recovery rate.

Maintaining System Integrity

Operating at over 1700 K under a strong vacuum places immense stress on the furnace materials and seals. Any leak would compromise the vacuum, halt the reaction, and potentially introduce contaminants, making high-quality construction an absolute necessity.

Making the Right Choice for Your Process

The design and operation of the furnace must align with your primary production goal.

- If your primary focus is energy efficiency: Prioritize achieving the lowest possible stable vacuum, as this directly reduces the required reaction temperature and overall energy consumption.

- If your primary focus is product yield and purity: Concentrate on creating a steep, stable temperature gradient between the reduction and condensation zones to ensure rapid and complete separation of magnesium vapor from CO gas.

- If your primary focus is operational reliability: Invest in robust furnace materials and high-integrity sealing technology to maintain consistent vacuum and temperature profiles under extreme conditions.

Ultimately, the vacuum vertical tube furnace is the critical instrument that makes modern carbothermal magnesium production possible by providing precise control over temperature, pressure, and physical separation.

Summary Table:

| Function | Key Feature | Benefit in Magnesium Production |

|---|---|---|

| Enables Reaction | Creates High Vacuum | Lowers required reaction temperature, saving energy |

| Separates Product | Vertical Design with Temperature Gradient | Allows magnesium vapor to condense separately from byproducts |

| Ensures Purity | Zoned Temperature Control | Prevents back-reactions, maximizing yield and metal purity |

| Maintains Process | Robust Seals & Materials | Provides operational reliability under extreme conditions |

Ready to Optimize Your High-Temperature Metal Production Process?

Producing high-purity metals like magnesium requires precise control over temperature and atmosphere. The challenges of energy efficiency, product yield, and operational reliability are exactly what our furnaces are engineered to solve.

KINTEK's advanced vacuum vertical tube furnaces are designed for processes just like carbothermal reduction. Backed by expert R&D and manufacturing, we offer Muffle, Tube, Rotary, Vacuum, and CVD systems, all customizable for your unique needs.

Let us help you achieve:

- Higher Purity & Yield with precise temperature zoning.

- Reduced Energy Costs through efficient low-pressure operation.

- Unmatched Reliability with robust construction for demanding environments.

Contact us today to discuss how a custom furnace solution can enhance your lab's capabilities. Get in Touch with Our Experts

Visual Guide

Related Products

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- Why is a tube furnace utilized for the heat treatment of S/C composite cathode materials? Optimize Battery Stability

- What recent improvements have been made to lab tube furnaces? Unlock Precision, Automation & Safety

- How is a Vertical Tube Furnace used for fuel dust ignition studies? Model Industrial Combustion with Precision

- What is an example of a material prepared using a tube furnace? Master Precise Material Synthesis

- How does a vertical tube furnace achieve precise temperature control? Unlock Superior Thermal Stability for Your Lab