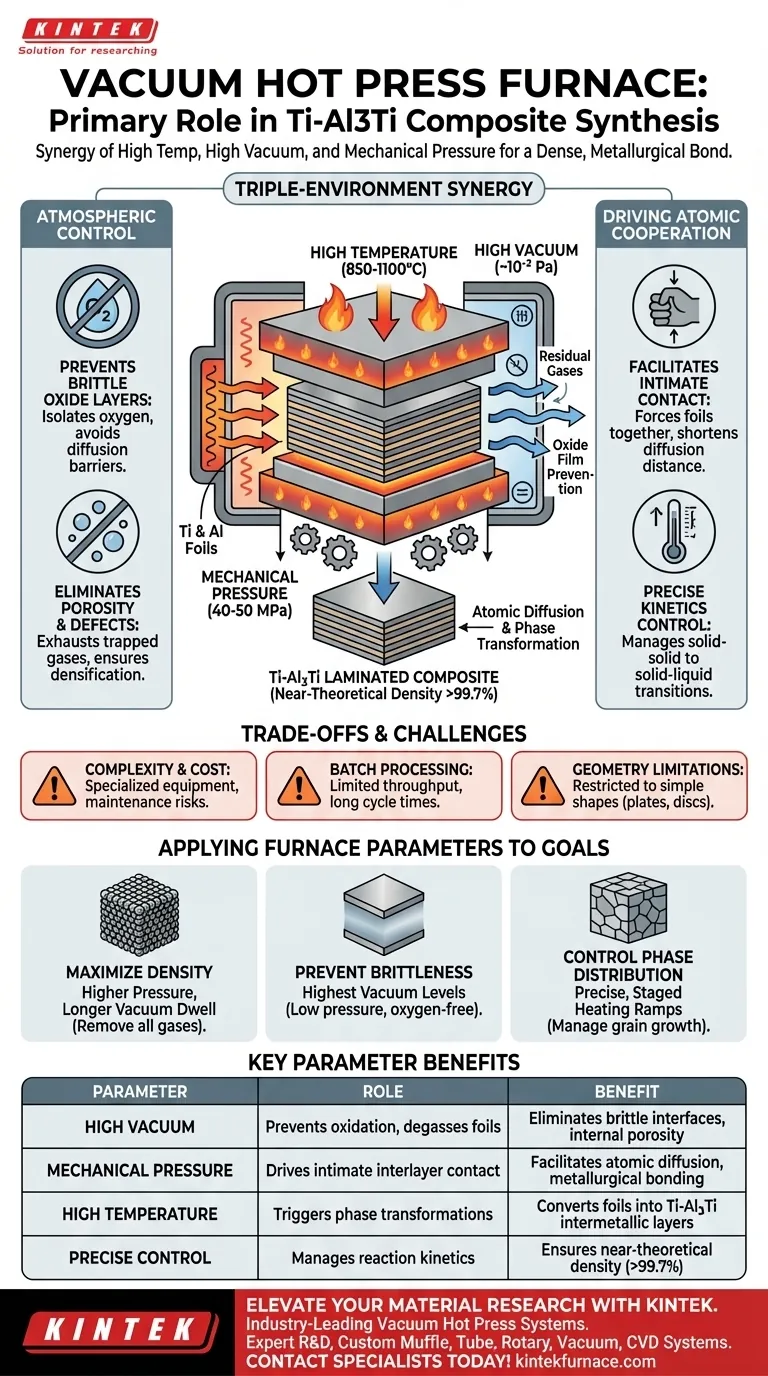

The primary role of a vacuum hot press furnace in synthesizing Ti-Al3Ti laminated composites is to provide a controlled, triple-environment consisting of high temperature, high vacuum, and mechanical pressure. This synergy ensures that reactive titanium and aluminum foils are converted into a dense, metallurgical bond by preventing oxidation, removing interstitial gases, and facilitating atomic diffusion and phase transformations.

Core Takeaway: A vacuum hot press furnace functions as a high-precision reactor that simultaneously protects reactive metals from environmental degradation and applies the physical force necessary to drive atomic-level bonding and densification.

The Synergistic Impact of Atmospheric Control

Preventing the Formation of Brittle Oxide Layers

Titanium and aluminum are highly reactive metals that oxidize almost instantly at the high temperatures required for processing. The high vacuum environment (often reaching $1 \times 10^{-2}$ Pa) effectively isolates oxygen to prevent the formation of oxide films.

If these oxide layers were allowed to form, they would act as a physical barrier, hindering atomic diffusion and creating brittle interfaces that compromise the composite's structural integrity.

Eliminating Internal Porosity and Gas Defects

Beyond preventing oxidation, the vacuum environment is critical for exhausting residual gases trapped between the stacked metal foils. By removing these gases before and during compression, the furnace prevents the formation of gas pores within the final material.

This degassing process is essential for achieving near-theoretical density, often exceeding 99.7%, which is required for high-performance applications.

Driving Atomic Diffusion and Phase Transformation

Facilitating Intimate Interlayer Contact

The application of mechanical pressure (typically ranging from 40 to 50 MPa) forces the metal foils into close physical contact at the microscopic level. This pressure eliminates gaps and shortens the distance required for titanium and aluminum atoms to migrate across the interface.

This physical forcing is the primary driver for solid-state metallurgical bonding, allowing the materials to join without macroscopic defects.

Precise Control of Reaction Kinetics

The furnace provides the high thermal energy (often between 850°C and 1100°C) necessary to trigger phase transformations. Precise heating allows the material to transition from simple solid-solid diffusion to complex solid-liquid reactions.

This controlled heating sequence is what specifically enables the conversion of raw metal foils into a sophisticated Ti-Al3Ti intermetallic compound composite with tailored microstructures.

Understanding the Trade-offs and Challenges

Equipment and Operational Complexity

The necessity of maintaining a high vacuum while applying significant mechanical force at extreme temperatures requires highly specialized and expensive equipment. Maintaining vacuum seals and heating elements under these dual stresses increases the risk of mechanical failure and high maintenance costs.

Production Throughput Constraints

Vacuum hot pressing is inherently a batch processing method, which limits the volume of material that can be produced at one time. The time required to achieve a high vacuum and the subsequent slow cooling cycles needed to prevent thermal shock further reduce overall production efficiency.

Material Size and Geometry Limitations

Because the process relies on the application of unidirectional pressure, it is largely restricted to simple geometries like plates or discs. Scaling the process for large-scale components or complex three-dimensional shapes remains a significant technical and economic challenge.

Applying Furnace Parameters to Your Goals

How to Apply This to Your Project

To achieve the best results with a vacuum hot press furnace, you must align the furnace parameters with your specific material requirements.

- If your primary focus is maximizing composite density: Prioritize a higher mechanical pressure and a longer vacuum dwell time to ensure all interstitial gases are removed before the final diffusion phase.

- If your primary focus is preventing interface brittleness: Focus on maintaining the highest possible vacuum levels (low pressure) to ensure the aluminum surfaces remain free of oxygen during the initial heating stage.

- If your primary focus is controlling phase distribution: Use precise, staged heating ramps to manage the transition from solid-state diffusion to solid-liquid reactions, preventing uncontrolled grain growth.

The vacuum hot press furnace remains the definitive tool for creating high-performance metal laminates by forcing atomic cooperation in a perfectly protected environment.

Summary Table:

| Parameter | Role in Synthesis | Benefit for Ti-Al3Ti Composites |

|---|---|---|

| High Vacuum | Prevents oxidation & degasses foils | Eliminates brittle interfaces and internal porosity |

| Mechanical Pressure | Drives intimate interlayer contact | Facilitates atomic diffusion and metallurgical bonding |

| High Temperature | Triggers phase transformations | Converts metal foils into Ti-Al3Ti intermetallic layers |

| Precise Control | Manages reaction kinetics | Ensures near-theoretical density (>99.7%) |

Elevate Your Material Research with KINTEK

Ready to achieve superior density and phase control in your Ti-Al3Ti composites? KINTEK provides industry-leading Vacuum Hot Press systems designed for the rigorous demands of advanced metallurgy.

Backed by expert R&D and manufacturing, we offer a full range of customizable Muffle, Tube, Rotary, Vacuum, and CVD systems tailored to your unique lab high-temp needs.

Contact our specialists today to discover how our precision engineering can drive your next breakthrough in material synthesis!

Visual Guide

Related Products

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- 600T Vacuum Induction Hot Press Vacuum Heat Treat and Sintering Furnace

- 9MPa Air Pressure Vacuum Heat Treat and Sintering Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

People Also Ask

- What are the key benefits of using Vacuum Hot Press equipment in manufacturing? Achieve Superior Material Quality and Performance

- What are the available pressing force and temperature ranges for vacuum hot pressing? Optimize Your Material Processing

- How does a hot pressing (HP) system achieve full densification? Achieve 100% Density in Ti-5Al-4W-2Fe Alloys

- What is the difference between hot pressing and sintering? Choose the Right Process for Your Materials

- What role does a high-strength graphite mold play in the hot pressing and sintering of Ag-Ti2SnC? Boost Densification

- What alternative mold materials are used in Spark Plasma Sintering (SPS)? Avoid Carbon Contamination Effectively

- What are the advantages of using a HIP sintering system over conventional sintering for Bismuth Telluride composites?

- What is the process of vacuum hot pressing? Achieve Ultra-Dense, High-Purity Materials