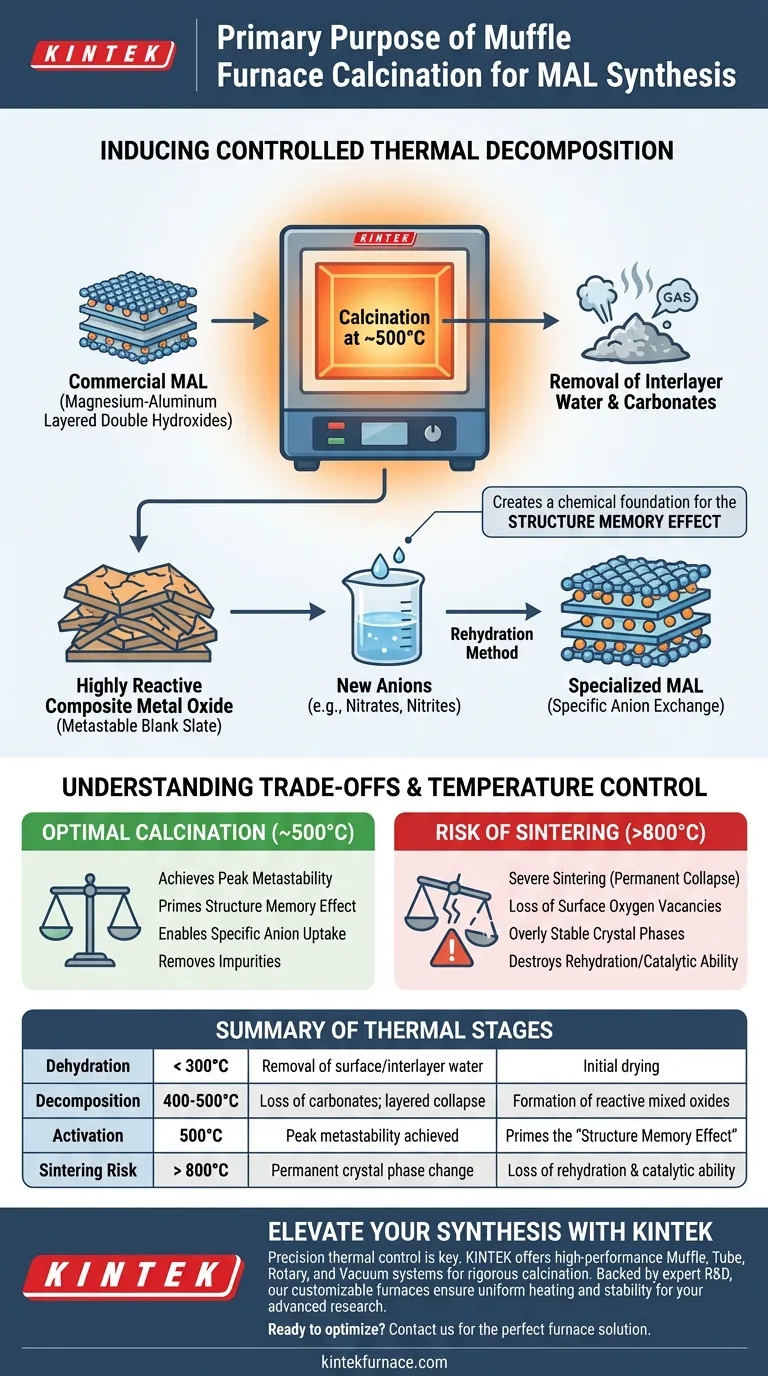

The primary purpose of using a muffle furnace for calcining commercial magnesium-aluminum layered double hydroxides (MAL) is to induce controlled thermal decomposition. By subjecting the material to temperatures around 500°C, the furnace effectively removes interlayer carbonate ions and chemically bound water, causing the original layered structure to collapse into a highly reactive composite metal oxide.

Core Takeaway This calcination process is not merely about drying; it creates a chemical foundation for the structure memory effect. By stripping away existing anions and collapsing the layers, you prepare the material to regenerate its layered structure during rehydration, allowing for the precise insertion of specific target ions like nitrates or nitrites.

The Mechanism of Thermal Decomposition

Removal of Interlayer Species

The immediate function of the muffle furnace is to drive off volatile components.

Commercial MAL often contains carbonate ions and water molecules trapped between its layers.

At 500°C, these components are vaporized and expelled, which is impossible to achieve with standard drying methods.

Structural Collapse and Oxide Formation

As the water and carbonates are removed, the characteristic layered structure of the hydroxide acts unpredictably.

It collapses, transforming the material into a mixed metal oxide solution (magnesium and aluminum oxides).

This transformation creates a disordered, high-surface-area intermediate that is chemically distinct from the starting material.

Facilitating the Structure Memory Effect

Creating a "Blank Slate"

The mixed metal oxides produced in the furnace are metastable.

They possess a "memory" of their original layered configuration.

This state is a prerequisite for the subsequent rehydration method, as the material is now primed to reform its layers when exposed to an aqueous solution.

Enabling Specific Anion Exchange

The ultimate goal of this calcination is often to synthesize MAL with specific anions that are difficult to introduce directly.

Because the original carbonate ions have been removed by the furnace, the reforming structure will eagerly absorb new anions available in the solution.

This allows for the synthesis of specialized MAL variants intercalated with nitrate or nitrite ions.

Understanding the Trade-offs

The Risk of Over-Calcination (Sintering)

While high heat is necessary, excessive temperature control is critical.

If the furnace temperature significantly exceeds the optimal range (e.g., reaching 800°C), the material may suffer from severe sintering.

This causes the pore structure to collapse permanently and reduces the concentration of surface oxygen vacancies, effectively destroying the material's ability to rehydrate or act as a catalyst.

Balancing Crystallinity and Activity

There is a delicate balance between removing impurities and maintaining surface activity.

Insufficient heating (below 400–500°C) may leave residual carbonates, blocking the uptake of new ions.

Conversely, extended exposure to high heat can lead to the formation of overly stable crystal phases (like spinels) that resist rehydration, nullifying the structure memory effect.

Making the Right Choice for Your Synthesis

To ensure successful synthesis, align your furnace parameters with your specific chemical goals:

- If your primary focus is utilizing the structure memory effect: Ensure the temperature is strictly maintained around 500°C to remove carbonates without permanently sintering the oxides.

- If your primary focus is synthesizing specific anion-intercalated MAL: Confirm that your calcination duration is sufficient to fully decompose the precursor, creating a "clean" oxide ready for nitrate or nitrite absorption.

By precisely controlling the thermal decomposition environment, you transform a standard commercial precursor into a tunable platform for advanced material synthesis.

Summary Table:

| Process Stage | Temperature | Physical/Chemical Change | Purpose |

|---|---|---|---|

| Dehydration | < 300°C | Removal of surface/interlayer water | Initial drying |

| Decomposition | 400°C - 500°C | Loss of carbonates; layered collapse | Formation of reactive mixed oxides |

| Activation | 500°C | Peak metastability achieved | Primes the "Structure Memory Effect" |

| Sintering Risk | > 800°C | Permanent crystal phase change | Loss of rehydration & catalytic ability |

Elevate Your Material Synthesis with KINTEK

Precision thermal control is the difference between a successful structure memory effect and permanent material sintering. Backed by expert R&D and manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for the rigorous demands of chemical calcination. Whether you are synthesizing specialized MAL variants or advanced catalysts, our customizable lab high-temp furnaces provide the uniform heating and temperature stability your research requires.

Ready to optimize your calcination process? Contact us today to find the perfect furnace solution for your unique laboratory needs.

Visual Guide

References

- Minxuan Zhong, You Wu. Corrosion Protection of Steel by NO3− and NO2− Intercalated Mg-Al Layered Double Hydroxides in Simulated Pore Solutions of Alkali-Activated Slag. DOI: 10.3390/met14010111

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the primary role of a muffle furnace in the annealing process of AlCrTiVNbx alloys? Enhance Alloy Strength

- What are the applications of a laboratory muffle furnace in biochar evaluation? Optimize Your Biomass Research

- What is the function of high-temperature furnaces in biogenic hydroxyapatite conversion? Achieve High-Purity Biomaterials

- What is the function of a box muffle furnace in nanoparticle stabilization? Optimize Active Ingredient Efficacy

- What are the high-temperature applications of a digital muffle furnace? Achieve Precise Thermal Control for Your Lab

- What is the function of a high-temperature muffle furnace in aluminum borate nanowire processing?

- What were the results of annealing silicon-based material in the muffle furnace? Achieve Enhanced Conductivity for Semiconductors

- What role do muffle furnaces play in the ceramics industry? Essential for Precision Firing and Purity