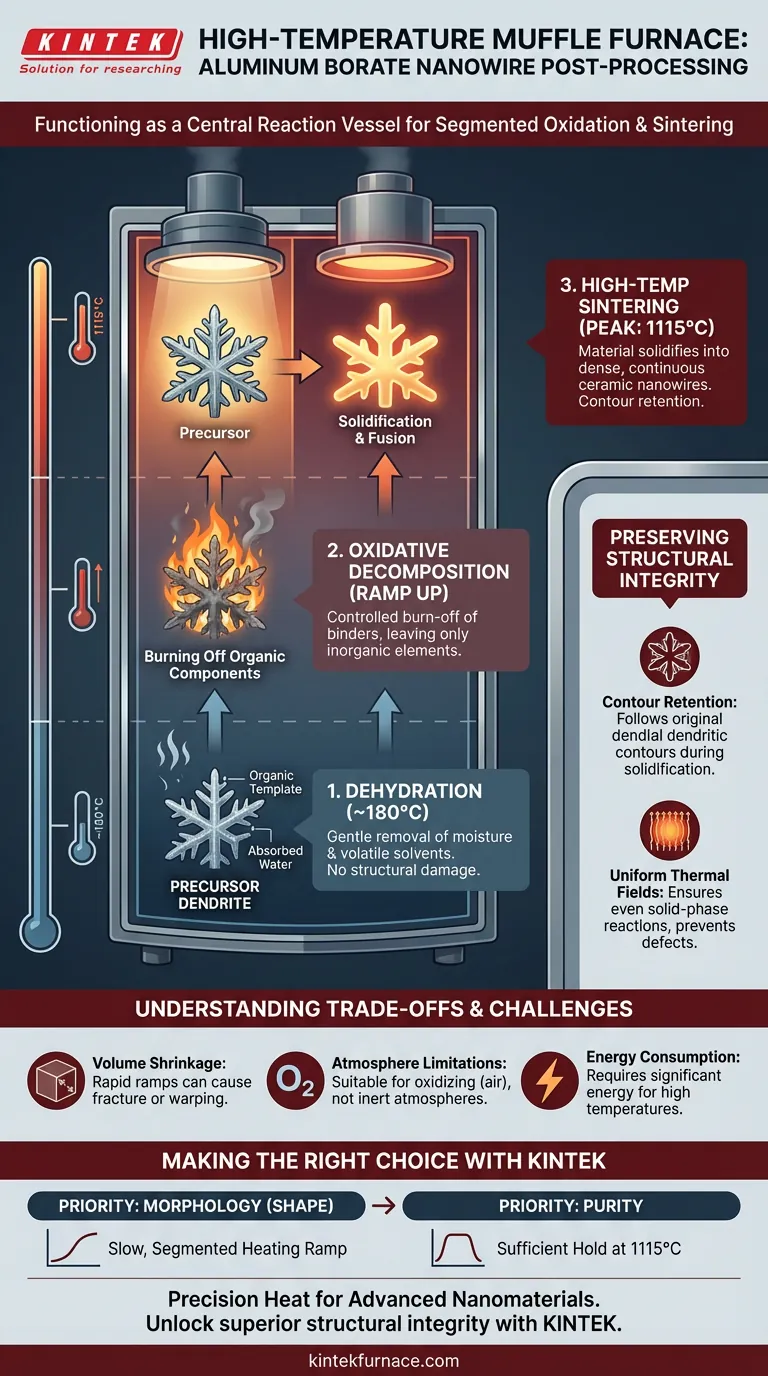

In the post-processing of aluminum borate nanowires, a high-temperature muffle furnace functions as the central reaction vessel for segmented oxidation and sintering. It executes a precise thermal program that first dehydrates the precursor at lower temperatures (around 180°C) and then ramps up to 1115°C to decompose organic components. This controlled high-heat environment forces the molten intermediate material to solidify into continuous ceramic nanowires that retain the specific shape of the original precursor dendrites.

Core Takeaway The muffle furnace is not merely a heater; it is a tool for structural preservation during phase transition. By precisely controlling the temperature curve, it allows for the destructive removal of organic binders while simultaneously fusing the remaining inorganic material into a stable, crystalline nanowire structure.

The Mechanics of Transformation

The production of aluminum borate nanowires is a multi-stage process where the furnace acts as the catalyst for chemical and physical change.

Segmented Oxidation

The process begins with low-temperature treatment. The furnace is programmed to hold at moderate temperatures, specifically around 180°C, to facilitate dehydration. This stage gently drives off absorbed water and volatile solvents without damaging the delicate precursor structure.

Oxidative Decomposition

As the temperature rises, the furnace creates an environment suitable for the oxidative decomposition of organic components. The precursor dendrites often contain organic templates or binders; the muffle furnace ensures these are burned off completely, leaving behind only the desired inorganic elements.

High-Temperature Sintering

The critical phase occurs at 1115°C. At this peak temperature, the remaining material undergoes sintering. The furnace ensures that the material, which may briefly pass through a molten state, solidifies into a dense, continuous ceramic form.

Preserving Structural Integrity

Beyond simple heating, the muffle furnace plays a vital role in defining the morphology (shape) of the final nanomaterial.

Contour Retention

One of the unique requirements for aluminum borate nanowires is maintaining the shape of the precursor. The furnace's controlled heating profile ensures that as the material solidifies, it follows the original dendritic contours. Without this precise control, the structure could collapse or melt into an amorphous blob.

Uniform Thermal Fields

While the primary reference focuses on the temperature curve, the stability provided by a muffle furnace is essential. A uniform thermal field ensures that the solid-phase reactions occur evenly throughout the batch. This prevents localized defects and ensures that the "continuous" nature of the nanowire is not interrupted by thermal stress cracks.

Understanding the Trade-offs

While the muffle furnace is essential for this process, it introduces specific challenges that must be managed.

Volume Shrinkage

Sintering inevitably leads to densification and volume shrinkage. If the furnace ramps temperature too quickly, the differential shrinkage between the surface and the core of the material can cause the nanowires to fracture or warp, destroying the dendritic shape.

Atmosphere Limitations

Standard muffle furnaces typically operate in an air (oxidizing) atmosphere. While this is perfect for oxidative decomposition of aluminum borate precursors, it is unsuitable for materials requiring inert atmospheres (like certain phosphides mentioned in supplementary contexts). Users must ensure their specific chemical reaction requires oxygen before selecting this equipment.

Energy Consumption

Reaching and maintaining temperatures of 1115°C requires significant energy. Inefficient loading of the furnace or poor insulation can lead to thermal gradients, where samples near the door process differently than those in the center, leading to inconsistent batch quality.

Making the Right Choice for Your Goal

When configuring a muffle furnace for nanowire post-processing, your settings should reflect your specific priority.

- If your primary focus is Morphology (Shape Retention): Prioritize a slow, segmented heating ramp. A gradual increase allows gases from organic decomposition to escape without rupturing the fragile dendritic structure before it hardens.

- If your primary focus is Purity: Ensure the furnace reaches and holds the peak temperature (1115°C) for sufficient time. This ensures the complete removal of all carbon-based residues and fully completes the phase transformation to the ceramic state.

Precision in the thermal curve is the difference between a pile of dust and high-performance nanowires.

Summary Table:

| Process Stage | Temperature | Primary Function |

|---|---|---|

| Dehydration | ~180°C | Removes moisture and volatile solvents without damaging precursors. |

| Oxidative Decomposition | Ramping Phase | Burns off organic templates and binders to leave inorganic elements. |

| High-Temp Sintering | 1115°C | Solidifies material into continuous ceramic nanowires with shape retention. |

| Morphology Control | Variable | Slow ramps prevent structural collapse and ensure contour retention. |

Precision Heat for Advanced Nanomaterials

Unlock superior structural integrity and purity in your research with KINTEK. Whether you are synthesizing aluminum borate nanowires or developing complex ceramic structures, our high-temperature solutions provide the uniform thermal fields necessary for delicate phase transitions.

Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of:

- Muffle & Tube Furnaces for precise segmented oxidation.

- Vacuum & CVD Systems for atmosphere-sensitive reactions.

- Rotary & Custom Lab Furnaces tailored to your unique scaling needs.

Don't let inconsistent heating ruin your morphology—partner with KINTEK for reliable, customizable thermal processing.

Contact Our Engineering Team Today

Visual Guide

References

- Quan Wan, Mingying Yang. Continuous 1D single crystal growth with high aspect ratio by oriented aggregation of dendrite. DOI: 10.1038/s43246-025-00737-y

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What temperature ranges are available for box furnaces? Find the Perfect Fit for Your Thermal Processes

- How is a muffle furnace utilized in the post-treatment for B-doped SiC nanowires? Ensure High Purity & Integrity

- What process conditions must a muffle furnace satisfy for CoNiCrAlY oxidation? Ensure Precise High-Temp Stability

- Why is precise temperature control in a muffle furnace critical for 1250°C homogenization of AlCoCrFeNi alloys?

- What are the common heating elements used in muffle furnaces and their corresponding temperature ranges? Choose the Right Element for Your Lab

- What are the typical technical specifications of a muffle furnace? Key Specs for Precise Heating

- What is the significance of muffle furnaces in materials science? Unlock Pure, High-Temperature Processing

- How are muffle furnaces utilized in dental laboratories? Essential for Sintering, Firing, and Casting