In the world of advanced materials, a muffle furnace is the indispensable tool for creating and validating high-performance ceramics. It provides an exceptionally controlled, high-temperature, and contaminant-free environment, which is critical for firing raw materials, testing the properties of finished goods, and conducting foundational research. Its role is to ensure that the final ceramic product is strong, reliable, and meets exact specifications.

The true value of a muffle furnace in ceramics goes beyond simply getting hot. Its defining feature is the "muffle"—an isolated chamber that protects the ceramic material from the heating elements and any fuel contaminants. This guarantees that the material's final properties are the result of the intended process, not external interference.

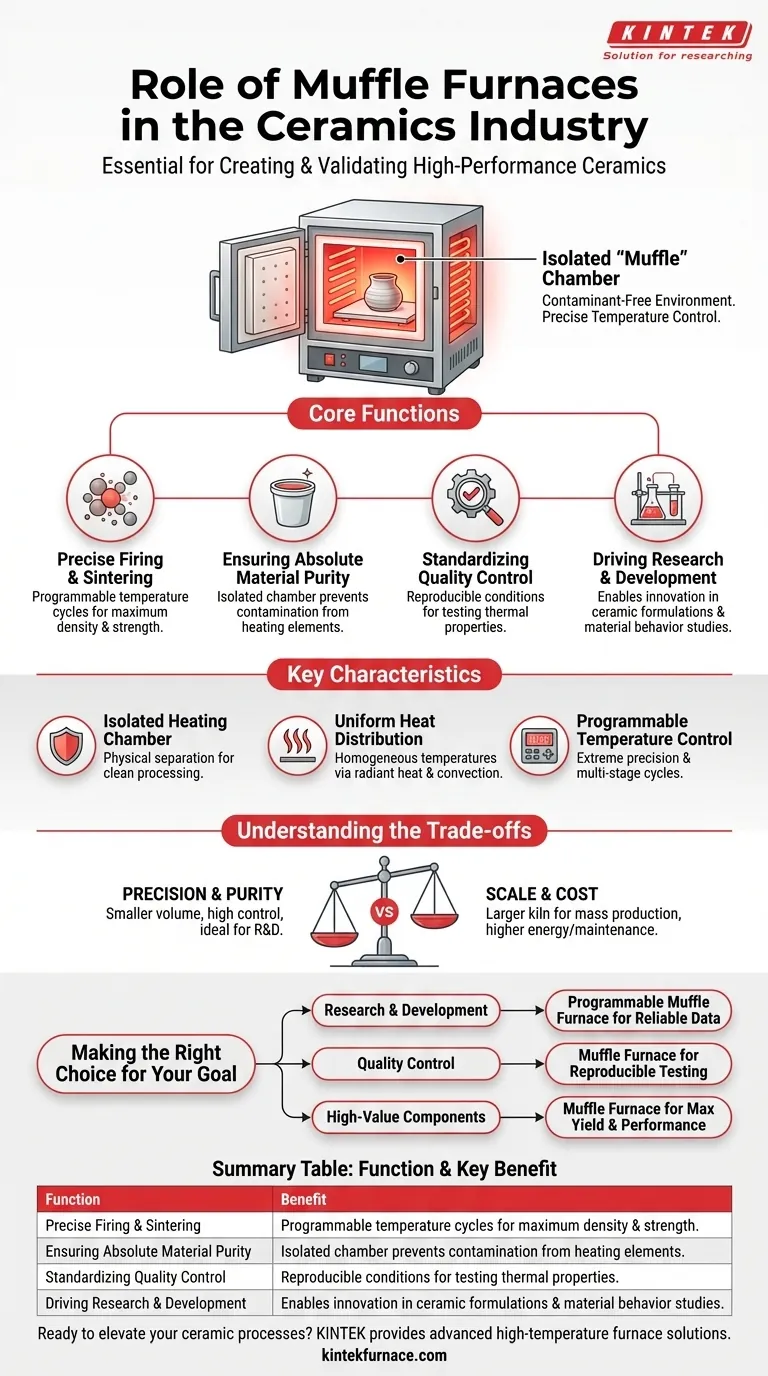

The Core Functions in Ceramics

A muffle furnace is not just an oven; it's a precision instrument. Its capabilities are central to achieving the unique properties that make ceramics valuable in industries from aerospace to electronics.

Achieving Precise Firing and Sintering

Ceramics are not merely dried; they are transformed by heat. This process, known as firing or sintering, requires an exact temperature schedule.

A muffle furnace's advanced control system allows operators to program precise heating rates, hold times at specific temperatures, and controlled cooling ramps. This prevents thermal shock and ensures that the ceramic particles bond correctly to achieve maximum density and strength.

Ensuring Absolute Material Purity

The defining characteristic of a muffle furnace is its isolated inner chamber. The heating elements are located outside this chamber, heating it from the exterior.

This design is critical because it prevents any byproducts from the heating elements (or fuel, in non-electric models) from contaminating the ceramic. For technical and electronic ceramics, where even trace impurities can ruin performance, this isolation is non-negotiable.

Standardizing Quality Control

To ensure a ceramic part will perform as expected, it must be tested under reproducible conditions. Muffle furnaces provide the perfect environment for this.

Manufacturers use them to fire test batches or subject finished components to extreme thermal cycles. This allows them to verify properties like thermal expansion, strength after firing, and resistance to degradation, ensuring every batch meets the required quality standard.

Driving Research and Development

In the laboratory, muffle furnaces are essential for innovation. Researchers use them to develop new ceramic formulations and study how different materials behave under extreme heat.

By exposing small samples to controlled conditions, scientists can quickly determine a material's composition, combustion characteristics, and potential applications without the cost and time of a full-scale production run.

Key Characteristics of a Muffle Furnace

The functions of a muffle furnace are enabled by a few key design principles that separate it from a standard kiln or oven.

Isolated Heating Chamber

The "muffle" itself is a chamber typically made from high-temperature, heat-resistant ceramic materials. This enclosure ensures the workload is physically separated from the heat source, guaranteeing a clean processing environment.

Uniform Heat Distribution

For a ceramic piece to fire properly, it must be heated evenly from all sides. Muffle furnaces are engineered to provide homogeneous temperatures throughout the chamber. They achieve this using a combination of radiant heat (from the hot walls of the muffle) and natural convection.

Programmable Temperature Control

Modern muffle furnaces use sophisticated digital controllers and thermocouples to maintain temperatures with extreme precision. This allows for complex, multi-stage firing cycles to be executed perfectly every time, a critical factor for repeatability in both manufacturing and research.

Understanding the Trade-offs

While essential, muffle furnaces are specialized tools with specific considerations. Understanding their limitations is key to using them effectively.

Precision Over Scale

A muffle furnace offers unparalleled control and purity, but typically in a smaller volume than a large industrial kiln. They are ideal for R&D, quality control, and the production of smaller, high-value components. For mass production of larger items like bricks or pottery, a larger, more conventional kiln is often more economical.

Electric Power and Cost

Most modern muffle furnaces are electric. This is the source of their clean operation, but it can also lead to higher energy consumption compared to large, gas-fired industrial kilns. The upfront cost of a precision muffle furnace is also higher than that of a simple oven due to its advanced controls and specialized materials.

Maintenance of Key Components

The components that enable a muffle furnace's precision—namely the heating elements and the thermocouple that measures temperature—are consumables. Over time and with high-temperature use, they will degrade and require replacement to maintain accuracy and performance.

Making the Right Choice for Your Goal

The decision to use a muffle furnace is driven by the need for thermal purity and precision.

- If your primary focus is research and material development: A programmable muffle furnace is non-negotiable for its ability to produce clean, repeatable, and reliable data.

- If your primary focus is quality control for technical ceramics: A muffle furnace is the only way to guarantee that your testing is not compromised by environmental variables.

- If your primary focus is producing high-value, sensitive components: The clean and uniform heating of a muffle furnace ensures maximum product yield and performance.

Ultimately, mastering the thermal process is the key to unlocking the full potential of any advanced ceramic material.

Summary Table:

| Function | Key Benefit |

|---|---|

| Precise Firing/Sintering | Achieves maximum density and strength with controlled temperature cycles |

| Material Purity | Isolated chamber prevents contamination for high-performance ceramics |

| Quality Control | Provides reproducible conditions for testing thermal properties |

| Research & Development | Enables innovation in ceramic formulations and material behavior studies |

Ready to elevate your ceramic processes with precision and purity? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Whether you're in R&D, quality control, or producing high-value ceramics, our furnaces ensure contaminant-free environments and exact temperature control for superior results. Contact us today to discuss how we can tailor a solution for your needs!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?

- What is the function of a muffle furnace in SiCf/Al-Mg pretreatment? Optimize Fiber Bonding with Thermal De-sizing

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What is the primary function of a muffle furnace in iron-modified activated carbon prep? Optimize Adsorption Sites

- What is the function of a muffle furnace during 500°C pre-calcination? Master CeZrPAl Support Synthesis