In essence, a porcelain furnace is the specialized kiln that transforms raw dental ceramic materials into finished, high-strength dental restorations. It uses precisely controlled heat to sinter, or fuse, powdered porcelain into durable and aesthetically accurate crowns, veneers, and bridges, ensuring they are fit for clinical use.

The true purpose of a dental porcelain furnace is not just to heat material, but to orchestrate a precise chemical and physical transformation. It converts fragile ceramic powder into a biocompatible, durable, and lifelike restoration by creating the exact atmospheric and temperature conditions required for successful sintering.

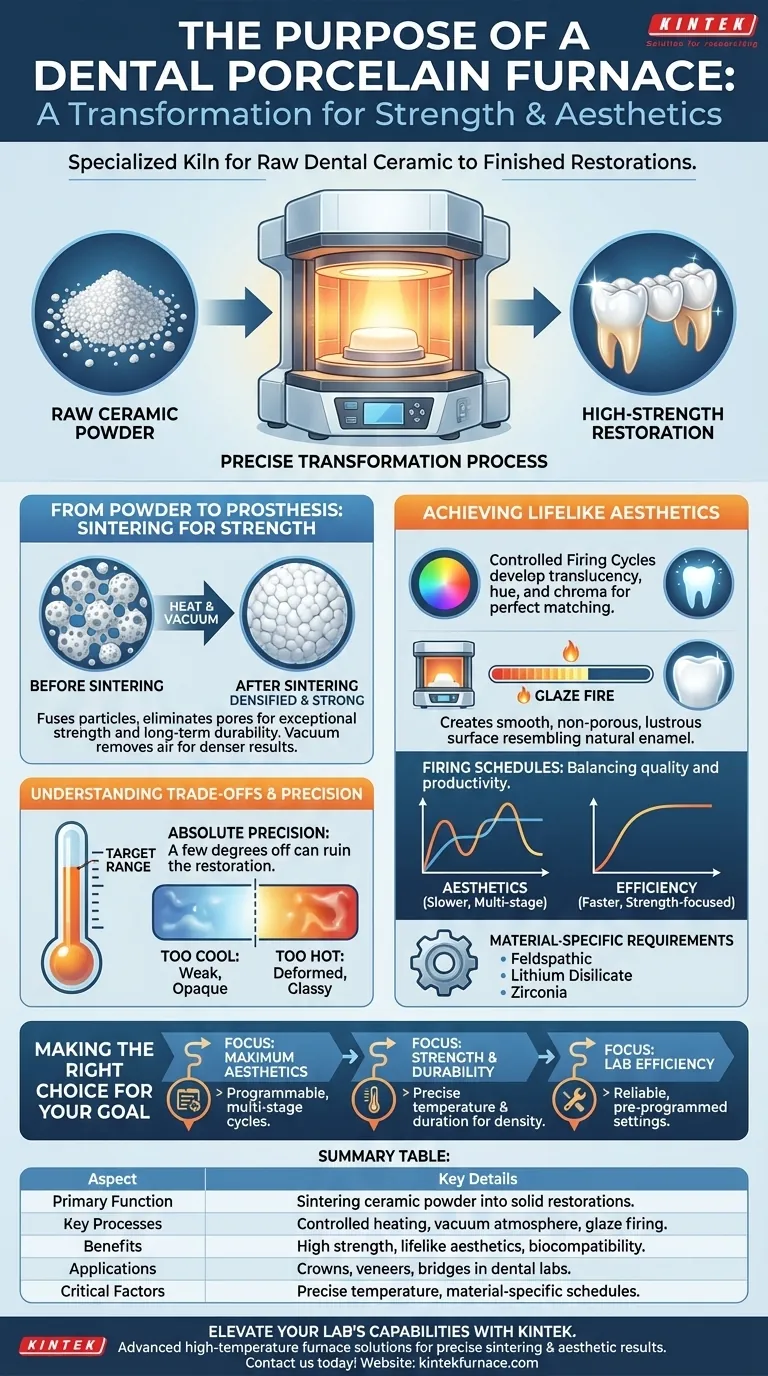

From Powder to Prosthesis: The Role of Sintering

A porcelain furnace's primary function is to facilitate a process called sintering. This is the fundamental step that gives a dental restoration its necessary strength and form.

What is Sintering?

Sintering is a thermal process where individual ceramic particles are heated to a point just below their melting temperature.

At this precise temperature, the particles fuse together, densifying the material and drastically reducing the empty space between them. This transforms the loose powder into a solid, coherent mass.

Why Sintering is Crucial for Strength

The initial ceramic material is mechanically weak and porous. It could never withstand the forces of chewing.

The sintering process eliminates these pores and creates a dense, interconnected structure. This new structure is what gives the final crown, bridge, or veneer its exceptional strength and long-term durability.

The Importance of Atmospheric Control

Modern furnaces also control the atmosphere during firing, often creating a vacuum.

Pulling a vacuum removes air and impurities trapped between the porcelain particles. This results in a denser, stronger, and more translucent final restoration, free of bubbles or imperfections.

Achieving Lifelike Aesthetics Through Controlled Firing

Beyond strength, the furnace is critical for achieving the aesthetic qualities that make a restoration indistinguishable from a natural tooth. This is not achieved with a single temperature, but through a programmed heating and cooling cycle.

Developing Translucency and Color

The specific temperatures and the duration the furnace holds them directly impact the restoration's final appearance.

This controlled process is how technicians develop the material's specific translucency, hue, and chroma (color intensity), ensuring a perfect match to the patient's adjacent teeth.

Creating Surface Texture and Glaze

The final stage of the process is often a "glaze fire." This is a quick, high-heat cycle that melts a thin outer layer of the ceramic.

This creates a smooth, non-porous, and lustrous surface that mimics the sheen of natural tooth enamel, while also making the restoration more stain-resistant and hygienic.

Understanding the Trade-offs

While essential, the operation of a porcelain furnace involves balancing critical variables. Mismanagement of this process can lead to a failed restoration.

The Need for Absolute Precision

A deviation of just a few degrees from the target temperature can ruin a restoration.

Too cool, and the material won't fully sinter, leaving it weak and opaque. Too hot, and it can deform, lose its color, or appear glassy and unnatural. The furnace's value lies in its precision.

The Impact of Firing Schedules

Different materials and aesthetic goals require different firing schedules. A highly complex, multi-stage program may produce superior aesthetics for an anterior veneer.

However, this may take significantly longer than a simpler, faster program suitable for a posterior crown where strength is the primary concern. Labs must balance quality with productivity.

Material-Specific Requirements

There is no universal firing program. Feldspathic porcelain, lithium disilicate, and zirconia all have unique and non-negotiable temperature requirements.

Using the wrong program for a given material will cause a complete failure. The furnace must be capable of executing these highly specific instructions without error.

Making the Right Choice for Your Goal

The furnace's role is to execute a specific material science protocol. How you leverage it depends on the desired outcome for the restoration.

- If your primary focus is maximum aesthetics: You must use a furnace with highly programmable, multi-stage firing cycles to precisely control the development of color and translucency.

- If your primary focus is strength and durability: The key is ensuring the furnace reaches and holds the correct sintering temperature for the specified duration to achieve full material density.

- If your primary focus is lab efficiency: Utilize furnaces with reliable, pre-programmed settings for common materials to minimize user error and optimize cycle times.

Understanding that the furnace is a tool for material transformation, not just heating, is the key to creating consistently successful dental restorations.

Summary Table:

| Aspect | Key Details |

|---|---|

| Primary Function | Sintering ceramic powder into solid restorations |

| Key Processes | Controlled heating, vacuum atmosphere, glaze firing |

| Benefits | High strength, lifelike aesthetics, biocompatibility |

| Applications | Crowns, veneers, bridges in dental labs |

| Critical Factors | Precise temperature, material-specific schedules |

Ready to elevate your dental lab's capabilities? KINTEK specializes in advanced high-temperature furnace solutions, including custom porcelain furnaces tailored for dental ceramics. Leveraging exceptional R&D and in-house manufacturing, we deliver precise sintering and aesthetic results for crowns, veneers, and bridges. Contact us today to discuss how our deep customization can meet your unique requirements and boost efficiency!

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What factors should be considered when choosing a dental sintering furnace? Ensure Quality and Efficiency for Your Lab

- What is the purpose of dental sintering furnaces? Transform Zirconia into Durable, High-Quality Dental Restorations

- Why is proper ventilation important in dental sintering furnaces? Ensure Quality and Safety in Your Lab

- What is the sintering process in dentistry? Unlock the Strength of Zirconia Restorations

- How has the sintering process innovated dental zirconia applications? Boost Strength, Precision, and Efficiency