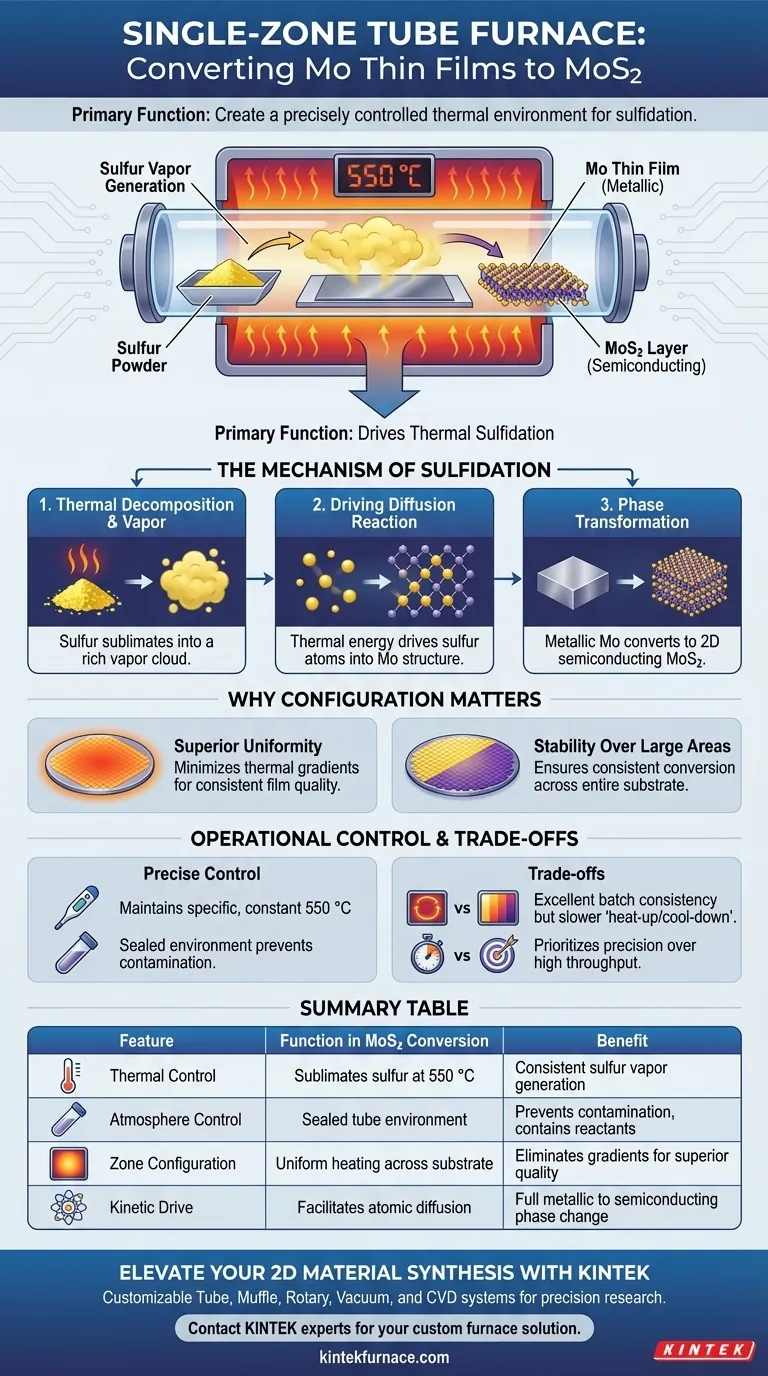

The primary function of a single-zone tube furnace in converting Molybdenum (Mo) thin films to Molybdenum Disulfide (MoS2) is to create a precisely controlled thermal environment that drives sulfidation. The furnace heats the reaction chamber to decompose elemental sulfur into vapor, which then diffuses into the solid Molybdenum film to trigger a complete phase transformation.

By maintaining a stable temperature (typically around 550 °C), the furnace facilitates the kinetic conditions required to convert a metallic thin film into a two-dimensional layered semiconductor.

The Mechanism of Sulfidation

Thermal Decomposition and Vapor Generation

The process begins by using the furnace's heat to thermally decompose elemental sulfur powder.

Instead of melting, the sulfur sublimates, generating a sulfur-rich vapor cloud within the sealed tube. This vapor serves as the essential reactant for the conversion process.

Driving the Diffusion Reaction

Once the sulfur vapor is generated, the furnace ensures it reaches the Molybdenum thin film.

The thermal energy drives a diffusion reaction where sulfur atoms penetrate the solid Molybdenum structure. This interaction is not merely surface-level coating but a deep chemical integration.

Phase Transformation

The ultimate goal of this thermal treatment is a fundamental change in material properties.

The furnace environment enables the phase transformation of the metallic Molybdenum film into a semiconducting MoS2 layer. This turns a conductive metal into a functional 2D material suitable for electronic applications.

Why Configuration Matters

Superior Uniformity

For the specific task of sulfurizing thin films, a single-zone configuration often outperforms multi-zone setups.

Research indicates that a one-zone furnace provides superior uniformity and repeatability in film quality. This configuration minimizes thermal gradients that could lead to uneven reaction rates across the substrate.

Stability Over Large Areas

Consistency is critical when processing large-area thin films.

Under optimized conditions, the single-zone furnace stabilizes the sulfurization reaction. This ensures that the conversion from Mo to MoS2 is consistent across the entire surface of the film.

Operational Control

Precise Temperature Regulation

The furnace must maintain a specific, constant temperature, often cited at 550 °C for this specific conversion process.

Digital controls regulate this heat to ensure the reaction kinetics remain stable without damaging the substrate or the forming film.

Sealed Reaction Environment

The tube furnace provides a sealed space, essential for managing the atmosphere.

This isolation prevents outside contaminants from interfering with the purity of the semiconductor and contains the sulfur vapor within the reaction zone.

Understanding the Trade-offs

Gradient Limitations

A single-zone furnace is designed for temperature uniformity, not for creating complex thermal gradients.

If a process requires different temperatures for the source material (sulfur) and the substrate—common in some Chemical Vapor Deposition (CVD) methods—a single-zone setup may require careful placement of precursors to manage evaporation rates solely via position relative to the heating element.

Throughput vs. Precision

While excellent for batch consistency, the "heat-up and cool-down" cycle of a tube furnace can be time-consuming.

However, for high-quality material synthesis where the phase transition must be exact, this trade-off in speed is necessary to achieve the correct crystal structure.

Making the Right Choice for Your Goal

To maximize the effectiveness of your MoS2 conversion process, consider your specific objectives:

- If your primary focus is film uniformity: Rely on the single-zone configuration to eliminate thermal gradients and ensure consistent sulfurization across the entire substrate.

- If your primary focus is process repeatability: Utilize the digital precision of the furnace to lock in the 550 °C parameter, ensuring identical conditions for every batch.

The single-zone tube furnace is not just a heater; it is the critical vessel that choreographs the delicate atomic exchange required to create next-generation 2D semiconductors.

Summary Table:

| Feature | Function in MoS2 Conversion | Benefit |

|---|---|---|

| Thermal Control | Sublimates sulfur powder at 550 °C | Consistent sulfur vapor generation |

| Atmosphere Control | Sealed tube environment | Prevents contamination and contains reactants |

| Zone Configuration | Uniform heating across substrate | Eliminates gradients for superior film quality |

| Kinetic Drive | Facilitates atomic diffusion | Full metallic to semiconducting phase change |

Elevate Your 2D Material Synthesis with KINTEK

Precision is paramount when converting Molybdenum films into high-quality MoS2 semiconductors. Backed by expert R&D and world-class manufacturing, KINTEK offers a comprehensive range of Tube, Muffle, Rotary, Vacuum, and CVD systems—all fully customizable to meet your specific research or production requirements.

Whether you need the superior uniformity of a single-zone furnace or the complex gradients of a multi-zone CVD setup, our lab high-temperature solutions deliver the stability and repeatability your materials demand.

Ready to optimize your thin-film sulfurization process?

Contact KINTEK experts today to find your custom furnace solution

Visual Guide

References

- Md Shariful Islam, Nowshad Amin. Pressure-dependent sulfurization of molybdenum thin films for high-quality MoS<sub>2</sub> formation. DOI: 10.1088/1755-1315/1500/1/012020

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1400℃ Controlled Inert Nitrogen Atmosphere Furnace

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- How do roller kilns and tube furnaces differ in their use of Alumina ceramic tubes? Compare Transport vs. Containment

- What are the limitations of vertical tube furnaces? Key Trade-offs for Lab Efficiency

- What role does a tube furnace play in the preparation of biochar-filled PVC composite precursors? Expert Synthesis Guide

- Why is a tube furnace required during the synthesis of phosphorus-doped nickel catalysts using high-purity nitrogen?

- What are the main differences in appearance between tube furnaces and box furnaces? Compare Shapes and Uses for Your Lab

- Why is a high-temperature tube furnace required for the annealing process during graphene growth? Optimize Substrates

- What critical process conditions does a tube atmosphere furnace provide for Sr2CuWO6? Control Atmosphere & Temperature

- How can operators prevent contamination in a horizontal electric furnace? Master Systematic Control for Purity