To prevent contamination in a horizontal electric furnace, you must adopt a systematic approach that goes beyond simple cleaning. This involves meticulously managing the furnace atmosphere, implementing strict material handling protocols, and maintaining the physical integrity of the chamber itself. Every item and gas entering the furnace is a potential source of contamination that can compromise your process and final product quality.

The core principle is that a furnace's internal environment is a closed system. True contamination control is not a single action but a continuous process of managing every material, gas, and procedure to ensure only the intended elements are present during operation.

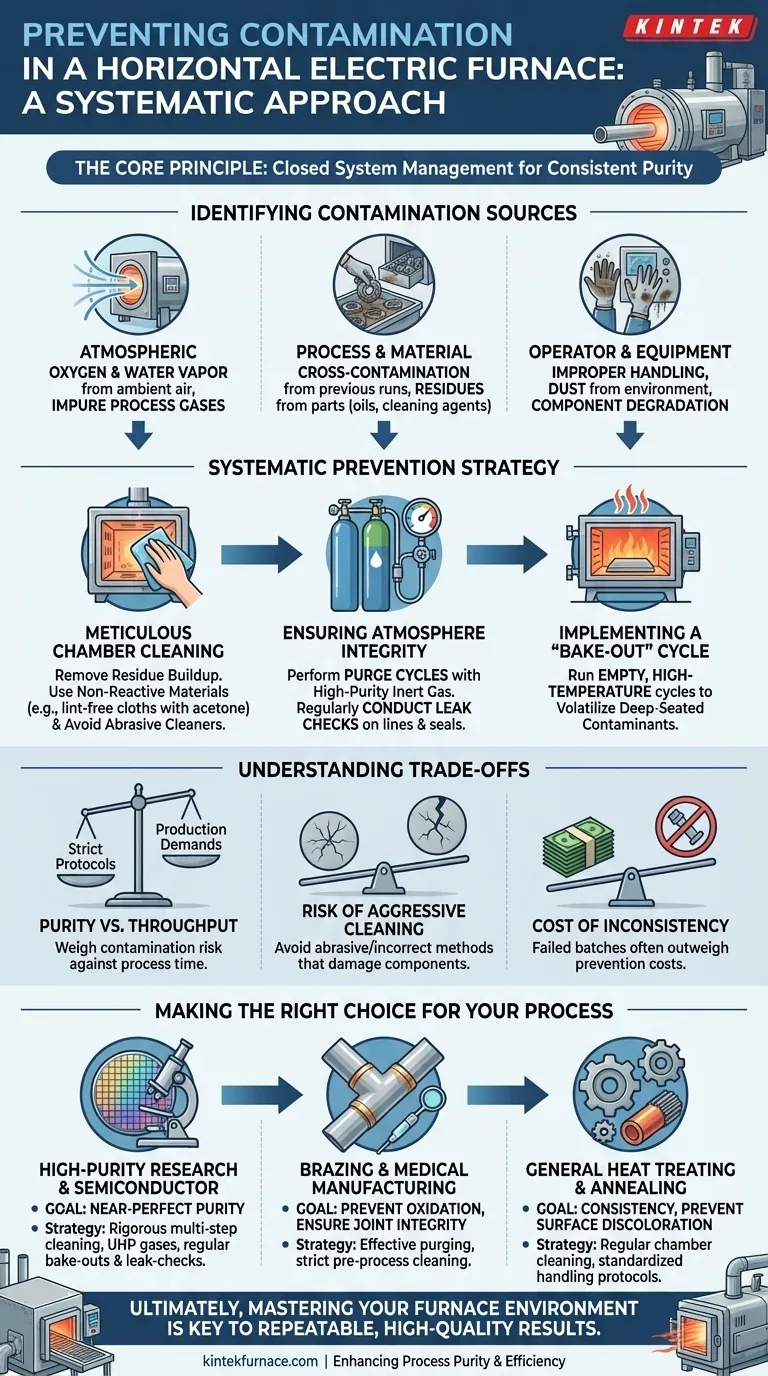

Identifying the Sources of Contamination

Before you can prevent contamination, you must understand where it originates. These sources can be broadly categorized into atmospheric, material, and operational factors.

Atmospheric Contaminants

The most common contaminants are oxygen and water vapor from the ambient air. These elements are highly reactive at elevated temperatures and can cause unwanted oxidation, leading to discoloration, poor adhesion in brazing, or altered material properties.

Even when using inert process gases like nitrogen or argon, the gas supply itself can be a source. Low-purity gas contains trace amounts of oxygen and moisture that can accumulate and impact sensitive processes.

Process and Material Contamination

Cross-contamination occurs when residue from a previous process run affects the current one. This is especially problematic when processing different alloys or materials in the same furnace, as trace elements can vaporize and redeposit.

The materials you load into the furnace are also a primary source. Fingerprints, cutting fluids, or cleaning agents left on parts can outgas at high temperatures, introducing hydrocarbons and other unwanted compounds.

Operator and Equipment Contamination

Operators can inadvertently introduce contaminants through improper handling, such as using dirty gloves or tools. Dust and debris from the surrounding shop environment can also be carried into the chamber.

Over time, furnace components themselves—like insulation, heating elements, or fixtures—can degrade and release particles or vapors into the process environment.

A Systematic Approach to Contamination Control

A robust strategy involves multiple layers of defense, turning contamination control from a reactive task into a proactive discipline.

Meticulous Chamber Cleaning

Regular cleaning is the foundation of contamination control. The goal is to remove any residue buildup or discoloration from the furnace's inner walls and hearth.

Use non-reactive materials for cleaning, such as lint-free cloths dampened with acetone or isopropyl alcohol. Avoid any cleaners that can leave a residue of their own. The frequency of cleaning depends entirely on your process sensitivity and throughput.

Ensuring Atmosphere Integrity

Before starting a process, you must remove the ambient air. This is achieved through purge cycles, where the chamber is repeatedly filled with a high-purity inert gas and vented to dilute the concentration of oxygen and moisture.

Verifying the integrity of your system is critical. Perform regular leak checks on all gas lines, fittings, and furnace door seals to ensure ambient air cannot be drawn into the chamber during operation.

Implementing a "Bake-Out" Cycle

For highly sensitive applications, running an empty, high-temperature bake-out cycle is an effective technique. This process helps to volatilize and purge deep-seated contaminants, like absorbed water vapor from the insulation, which a simple surface cleaning cannot remove.

Understanding the Trade-offs

Implementing rigorous contamination control is not without its challenges. It requires a balance between process purity, operational efficiency, and cost.

Purity vs. Throughput

Strict protocols, such as long purge cycles or frequent bake-outs, increase process time and reduce furnace throughput. You must weigh the acceptable level of contamination risk against your production demands.

The Risk of Aggressive Cleaning

While cleaning is essential, using the wrong methods can cause more harm than good. Abrasive materials can damage the furnace hot zone or fixtures, creating particles that become a new source of contamination. Likewise, incorrect chemical agents can react with furnace components.

The Hidden Cost of Inconsistency

Cutting corners on contamination control may seem efficient, but it often leads to inconsistent results, failed batches, and product rework. The cost of a single rejected batch frequently outweighs the investment in proactive contamination prevention.

Making the Right Choice for Your Process

Your contamination control strategy should be tailored to the specific requirements of your application.

- If your primary focus is high-purity research or semiconductor processing: Your goal is near-perfect purity. Implement rigorous multi-step cleaning, use ultra-high purity (UHP) gases, and perform regular bake-out and leak-check procedures.

- If your primary focus is brazing or medical device manufacturing: Your goal is preventing oxidation and ensuring joint integrity. Prioritize effective atmosphere purging and strict pre-process part cleaning to remove all oils and residues.

- If your primary focus is general heat treating or annealing: Your goal is consistency and preventing surface discoloration. Focus on regular chamber cleaning to prevent cross-contamination and standardized material handling protocols.

Ultimately, mastering your furnace environment is the key to achieving repeatable, high-quality results every time.

Summary Table:

| Contamination Source | Prevention Strategy | Key Benefit |

|---|---|---|

| Atmospheric (O2, H2O) | Use high-purity gases and purge cycles | Reduces oxidation and moisture effects |

| Material (residues, oils) | Implement strict cleaning and handling protocols | Prevents cross-contamination and outgassing |

| Operational (operator, equipment) | Regular maintenance and leak checks | Ensures system integrity and consistency |

Need a contamination-free furnace solution tailored to your lab? Leveraging exceptional R&D and in-house manufacturing, KINTEK provides diverse laboratories with advanced high-temperature furnace solutions. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by our strong deep customization capability to precisely meet unique experimental requirements. Contact us today to enhance your process purity and efficiency!

Visual Guide

Related Products

- Laboratory Quartz Tube Furnace RTP Heating Tubular Furnace

- Vacuum Heat Treat Sintering Furnace with Pressure for Vacuum Sintering

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1200℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is a quartz tube furnace and what is its primary use? Essential for Controlled High-Temp Processing

- How does the work process of a quartz tube furnace typically proceed? Master Precision Heating for Advanced Materials

- How does sample handling differ between vertical and horizontal tube furnaces? Choose the Right Furnace for Your Lab

- What is the use of a quartz tube furnace? For High-Purity, Observable Material Processing

- What are the common applications of quartz tube furnaces? Unlock Precision in High-Temp Processing