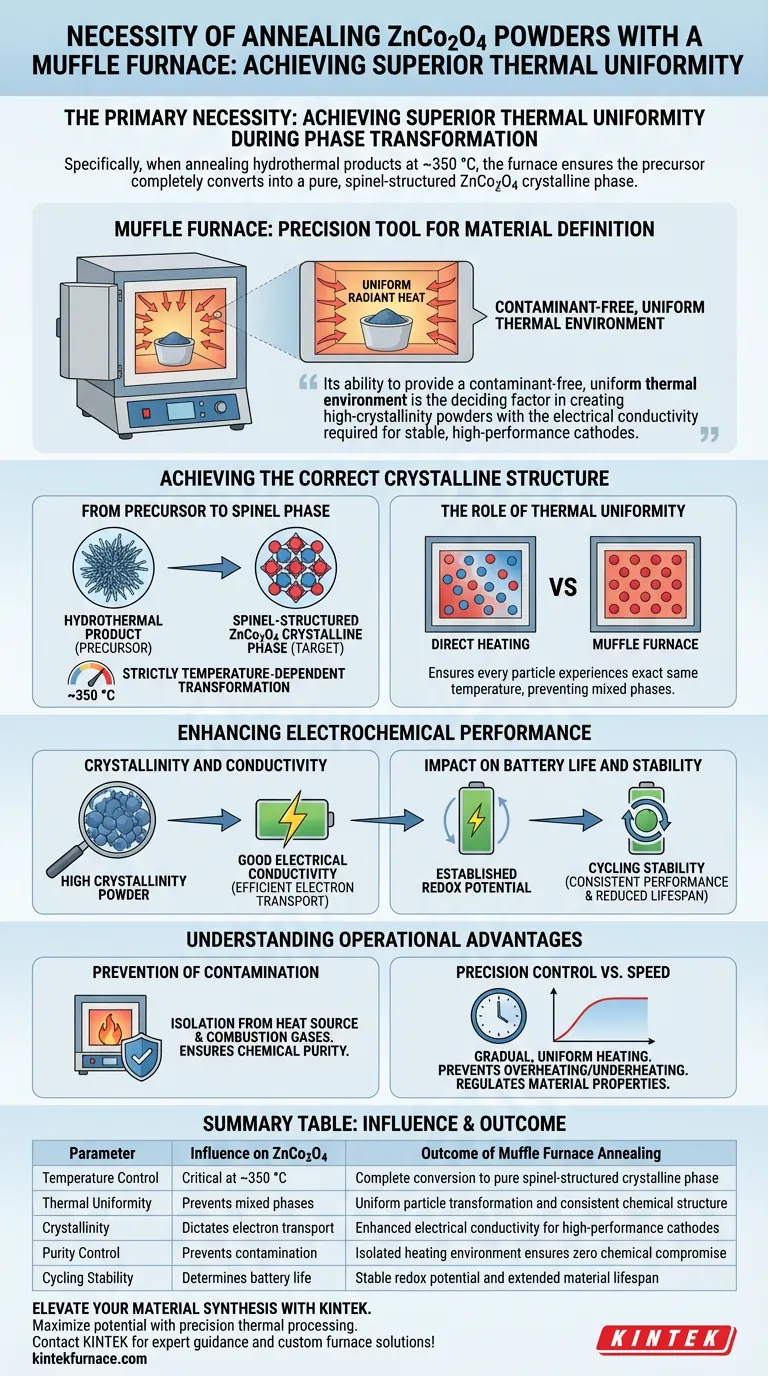

The primary necessity of using a muffle furnace for ZnCo2O4 powders is to achieve superior thermal uniformity during phase transformation. Specifically, when annealing hydrothermal products at temperatures around 350 °C, the furnace ensures the precursor completely converts into a pure, spinel-structured ZnCo2O4 crystalline phase.

The muffle furnace serves as a precision tool for material definition, not just heating. Its ability to provide a contaminant-free, uniform thermal environment is the deciding factor in creating high-crystallinity powders with the electrical conductivity required for stable, high-performance cathodes.

Achieving the Correct Crystalline Structure

From Precursor to Spinel Phase

The post-treatment process is a critical synthesis step where the raw hydrothermal product is chemically restructured.

For ZnCo2O4, the goal is to convert the precursor material into a specific spinel-structured crystalline phase. This transformation is strictly temperature-dependent and requires a stable environment to complete fully.

The Role of Thermal Uniformity

The distinguishing feature of a muffle furnace is its ability to radiate heat uniformly from the walls into the chamber.

Unlike direct heating methods, this ensures that every particle of the powder experiences the exact same temperature (e.g., 350 °C). This uniformity prevents the formation of "mixed phases," ensuring the entire batch achieves the target chemical structure.

Enhancing Electrochemical Performance

Crystallinity and Conductivity

The physical quality of the powder directly dictates its electronic properties.

High crystallinity, achieved through this controlled annealing, results in good electrical conductivity. In the context of cathode materials, conductivity is essential for efficient electron transport during operation.

Impact on Battery Life and Stability

The benefits of the muffle furnace extend to the end-use application of the powder.

The properties established during this annealing process—specifically the redox potential—directly determine the material's cycling stability. Without the uniform phase transformation provided by the furnace, the cathode material would likely suffer from inconsistent performance and reduced lifespan.

Understanding the Operational Advantages

Prevention of Contamination

A key operational advantage of the muffle furnace is the isolation of the sample from the heat source.

Heating elements are embedded in the furnace walls, meaning the sample is heated by radiation and does not come into direct contact with combustion gases or heating coils. This ensures the chemical purity of the ZnCo2O4 powder remains compromised.

Precision Control vs. Speed

While effective, this process relies on gradual, uniform heating rather than rapid thermal shock.

The control system maintains the target temperature to prevent overheating or underheating. This precision is necessary to regulate the material's properties, but it requires adherence to specific time and temperature protocols to be effective.

Making the Right Choice for Your Goal

To maximize the efficacy of your ZnCo2O4 post-treatment, consider the following parameters:

- If your primary focus is Phase Purity: Ensure the furnace is calibrated to maintain exactly 350 °C to guarantee complete transformation into the spinel structure.

- If your primary focus is Electrochemical Performance: Prioritize the duration of the anneal at the target temperature to maximize crystallinity and electrical conductivity.

Ultimately, the muffle furnace is the bridge between a raw precursor and a functional, high-stability electronic material.

Summary Table:

| Parameter | Influence on ZnCo2O4 | Outcome of Muffle Furnace Annealing |

|---|---|---|

| Temperature Control | Critical at ~350 °C | Complete conversion to pure spinel-structured crystalline phase |

| Thermal Uniformity | Prevents mixed phases | Uniform particle transformation and consistent chemical structure |

| Crystallinity | Dictates electron transport | Enhanced electrical conductivity for high-performance cathodes |

| Purity Control | Prevents contamination | Isolated heating environment ensures zero chemical compromise |

| Cycling Stability | Determines battery life | Stable redox potential and extended material lifespan |

Elevate Your Material Synthesis with KINTEK

Maximize the potential of your ZnCo2O4 powders with precision thermal processing. Backed by expert R&D and world-class manufacturing, KINTEK offers high-performance Muffle, Tube, Rotary, Vacuum, and CVD systems tailored for advanced lab research. Whether you need uniform phase transformation or customizable high-temperature solutions for unique battery materials, our equipment ensures high crystallinity and chemical purity every time.

Ready to optimize your cathode performance? Contact KINTEK today for expert guidance and custom furnace solutions!

Visual Guide

References

- Kiran Kumar Reddy Reddygunta, Aruna Ivaturi. Sheet-like ZnCo<sub>2</sub>O<sub>4</sub> microspheres and pomelo peel waste-derived activated carbon for high performance solid state asymmetric supercapacitors. DOI: 10.1039/d4se00182f

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- What are the environmental requirements for muffle furnace operation? Ensure Safety and Precision in Your Lab

- Why is the calcination process in a muffle furnace necessary for preparing bimetallic oxide CuCo2O4?

- What temperature precautions should be observed when using a muffle furnace? Ensure Safety and Longevity in Your Lab

- What are the different types of muffle furnaces based on appearance and shape? Choose the Right Furnace for Your Lab

- What is the role of a laboratory drying oven or hot plate in slurry processing? Optimize Composite Material Quality

- How does a high-temperature laboratory furnace contribute to the synthesis of binary magnesium-based alloys?

- What are the benefits of using a muffle furnace for aluminum-based self-lubricating composites? Maximize Matrix Hardness

- How are muffle furnaces used in rice laboratories? Essential for Accurate Ash and Moisture Analysis