In a rice laboratory, a muffle furnace is primarily used for two critical quality control procedures: determining the total ash content and measuring the moisture content of rice samples. These analyses rely on the furnace's ability to provide a precise, uniform, and extremely high-temperature environment that is free from contamination.

The core purpose of using a muffle furnace for rice analysis is to isolate its inorganic mineral content. By incinerating all organic material at a controlled high temperature, laboratories can accurately measure the mineral (ash) and moisture levels, which are fundamental indicators of the rice's quality, purity, and safety.

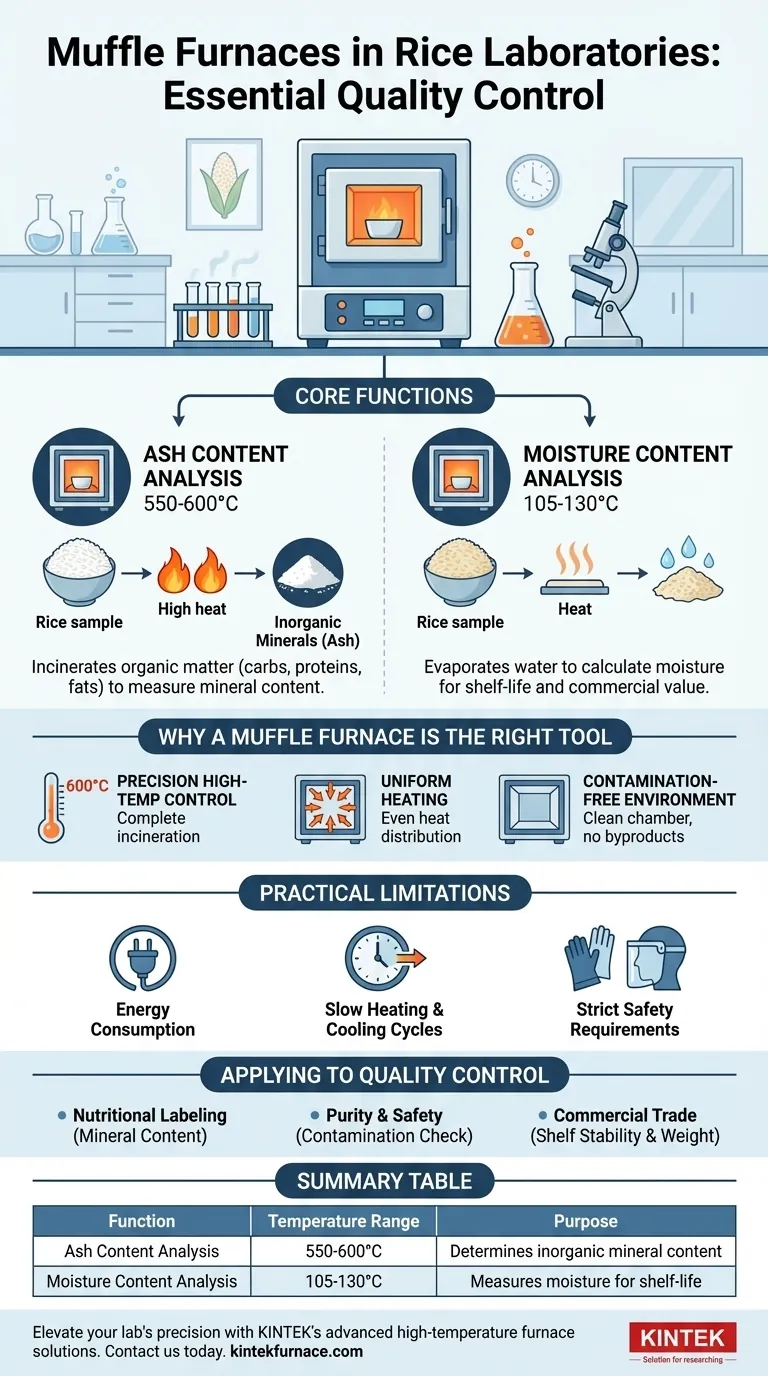

The Core Functions: Ash and Moisture Analysis

A muffle furnace is an essential tool for quantitative analysis, enabling labs to break down a rice sample into its most basic components through controlled heating.

Determining Ash Content

The primary use is for ashing. This process involves placing a precisely weighed rice sample in a crucible and heating it in the furnace to a very high temperature, typically between 550-600°C.

At this temperature, all organic matter—carbohydrates, proteins, fats, and vitamins—is completely burned away or incinerated.

The material left behind is the ash, which consists of the inorganic mineral components of the rice. Weighing this residue allows for an accurate calculation of the total mineral content, which is a key nutritional metric.

Measuring Moisture Content

While a drying oven is also used for this task, a muffle furnace can be set to a lower, controlled temperature (around 105-130°C).

At this temperature, all the water within the rice sample evaporates. By weighing the sample before and after this drying process, technicians can precisely calculate its moisture content. This figure is critical for determining shelf-life and commercial value.

Why a Muffle Furnace is the Right Tool

Not just any oven can perform these tasks. The unique design of a muffle furnace provides the specific environment required for accurate and repeatable scientific analysis.

Precision High-Temperature Control

Ashing requires temperatures that far exceed the capabilities of a standard laboratory oven. A muffle furnace is engineered to reach and maintain these extreme temperatures with high stability.

This ensures that the organic matter is completely incinerated, leaving only the true inorganic ash behind for an accurate measurement.

Uniform Heating

The furnace chamber is designed to distribute heat evenly through conduction, convection, and radiation.

This uniform heating ensures that the entire sample is processed consistently, preventing partial combustion or hot spots that would skew the final results.

Contamination-Free Environment

The term "muffle" refers to the inner chamber that isolates the sample from the heating elements. Modern electric muffle furnaces produce no byproducts of combustion.

This design creates a clean, contamination-free environment, ensuring that the final weight of the ash comes exclusively from the rice sample itself and not from any external source. This is vital for ensuring the safety and integrity of the analysis.

Understanding the Practical Limitations

While indispensable, muffle furnaces have operational characteristics that must be managed in a laboratory setting.

Significant Energy Consumption

Reaching and maintaining temperatures of 600°C or higher requires a substantial amount of electrical energy. The process is inherently energy-intensive.

Slow Heating and Cooling Cycles

A muffle furnace can take a significant amount of time to reach its target temperature and even longer to cool down. Most models rely on simple fan-based exhaust systems rather than active cooling.

This slow cooldown period can become a bottleneck in workflow for laboratories processing a high volume of samples.

Strict Safety Requirements

Operating at such extreme temperatures necessitates strict safety protocols. Technicians must use specialized tongs, heat-resistant gloves, and face shields to handle crucibles and prevent severe burns.

Applying This to Your Quality Control Process

The data from muffle furnace analysis directly informs key decisions about rice quality and safety.

- If your primary focus is nutritional labeling: Ash content analysis provides the definitive measure of the total mineral content in the rice.

- If your primary focus is purity and safety: An unusually high ash value can indicate inorganic contamination, such as sand, soil, or other adulterants.

- If your primary focus is commercial trade and storage: Accurate moisture content is essential for preventing spoilage, ensuring long-term shelf stability, and calculating the correct product weight for sale.

Ultimately, the muffle furnace is a foundational instrument for validating the quality, safety, and nutritional value of rice.

Summary Table:

| Function | Temperature Range | Purpose |

|---|---|---|

| Ash Content Analysis | 550-600°C | Determines inorganic mineral content by incinerating organic matter |

| Moisture Content Analysis | 105-130°C | Measures water evaporation to calculate moisture levels for shelf-life |

Elevate your laboratory's precision and efficiency with KINTEK's advanced high-temperature furnace solutions. Leveraging exceptional R&D and in-house manufacturing, we provide diverse labs with reliable muffle, tube, rotary, vacuum, atmosphere furnaces, and CVD/PECVD systems. Our strong deep customization capability ensures we meet your unique experimental needs for accurate ash and moisture analysis in rice quality control. Contact us today to discuss how our tailored solutions can enhance your quality assurance processes and drive better results!

Visual Guide

Related Products

- 1400℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace with Bottom Lifting

- 1700℃ High Temperature Muffle Oven Furnace for Laboratory

- 1800℃ High Temperature Muffle Oven Furnace for Laboratory

- Multi Zone Laboratory Quartz Tube Furnace Tubular Furnace

People Also Ask

- What is the core role of a muffle furnace in the synthesis of calcium oxide from eggshells? Achieve High-Purity CaO

- What is the primary function of a high-temperature box resistance furnace? Optimize Superalloy Homogenization

- How does the use of a 100-mesh sieve contribute to the performance consistency of magnetic chitosan carbon?

- What is the core function of a muffle furnace in CuO nanoparticle synthesis? Achieve Precision Calcination

- What key step does a Muffle Furnace perform in the determination of mineral content in Tenebrio molitor larvae?