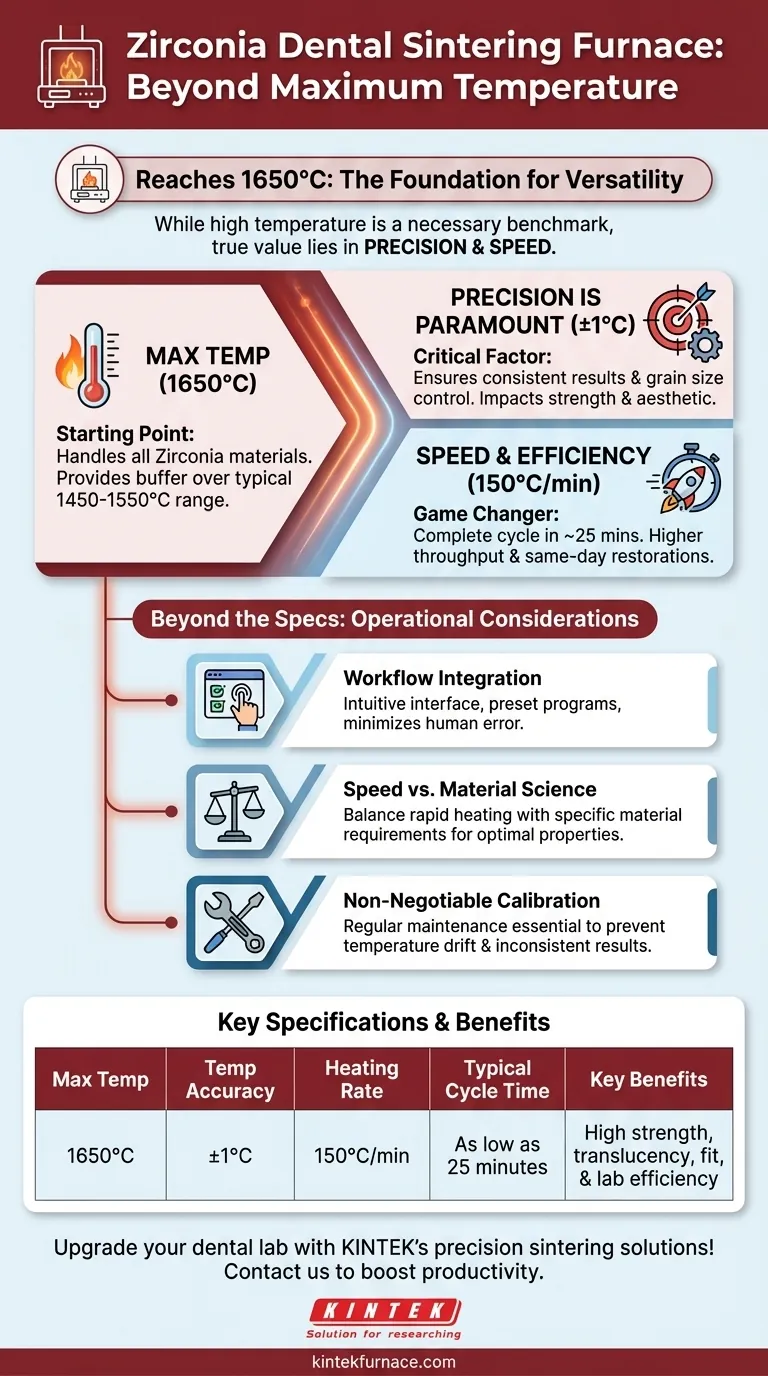

The Zirconia Dental Sintering Furnace reaches a maximum temperature of 1650°C. While this high temperature ceiling provides versatility for various zirconia materials, the true value of a modern furnace is found in its precision and speed. The ability to control temperature with extreme accuracy is what ensures the final restoration has the desired strength, translucency, and fit.

For dental laboratories, the goal is not merely heating a restoration; it's achieving a perfectly sintered final product. While a 1650°C maximum temperature is a necessary benchmark, the critical factors that determine quality and efficiency are temperature accuracy and the speed of the heating cycle.

Beyond Max Temp: What Defines Sintering Performance

The maximum temperature rating is a starting point, but it doesn't tell the whole story. The quality of a zirconia restoration depends on how precisely the heat is managed throughout the entire sintering cycle.

The Significance of 1650°C

This temperature provides a significant buffer above the typical sintering temperatures required for most dental zirconia, which range from 1450°C to 1550°C. This ensures the furnace can handle virtually any zirconia material on the market, including high-translucency and multi-layered types.

Precision is Paramount: The ±1°C Accuracy

The most critical specification for consistent results is temperature accuracy. This furnace maintains a fluctuation of just ±1°C.

This level of precision is achieved through high-quality sensors and automatic feedback control. It is essential for controlling the material's grain size during sintering, which directly impacts the final restoration's strength and aesthetic appearance.

Speed and Efficiency: The 150°C/min Heating Rate

A modern furnace can heat up at a rate of 150°C per minute. This rapid heating capability enables a complete sintering cycle to be finished in as little as 25 minutes.

For a dental lab, this translates directly to higher throughput, reduced patient wait times, and improved overall operational efficiency. It allows for same-day restorations without compromising quality.

Understanding the Operational Considerations

While the technical specifications are impressive, how they function in a real-world lab environment is what truly matters.

Workflow Integration and Ease of Use

To ensure consistent results across different technicians, the furnace must be easy to operate. An intuitive touch screen with built-in preset programs minimizes the risk of human error.

Technicians can quickly select a proven cycle or easily fine-tune parameters for custom cases, ensuring repeatability and reducing the training burden.

The Trade-off Between Speed and Material Science

While a 25-minute cycle is a major advantage, it's crucial to follow the zirconia manufacturer's specific recommendations. Some advanced materials may require slower heating or cooling rates to achieve their optimal properties.

A furnace with flexible, programmable cycles allows you to balance the need for speed with the strict requirements of the material being used.

The Non-Negotiable Role of Calibration

The advertised ±1°C accuracy is contingent on proper maintenance. Regular furnace calibration is essential to ensure the temperature sensor and controller are performing correctly.

Without routine checks, temperature drift can occur, leading to inconsistent sintering results and compromising the quality of your restorations.

Making the Right Choice for Your Lab

Selecting a furnace requires looking beyond a single number and matching its capabilities to your primary business goals.

- If your primary focus is high-volume production: Prioritize furnaces with rapid heating rates and short total cycle times to maximize your lab's daily output.

- If your primary focus is maximum quality and aesthetics: Scrutinize the temperature accuracy (±1°C) and the ability to customize programs for specific, high-end zirconia materials.

- If your primary focus is operational simplicity: Look for features like intuitive touch screens and a wide range of reliable preset programs to ensure consistency and minimize user error.

Ultimately, a superior furnace is defined not just by the heat it can generate, but by the precision, speed, and control with which it applies it.

Summary Table:

| Feature | Specification |

|---|---|

| Maximum Temperature | 1650°C |

| Temperature Accuracy | ±1°C |

| Heating Rate | 150°C/min |

| Typical Cycle Time | As low as 25 minutes |

| Key Benefits | High strength, translucency, fit, and lab efficiency |

Upgrade your dental lab with KINTEK's precision sintering solutions! Leveraging exceptional R&D and in-house manufacturing, we provide advanced high-temperature furnaces tailored for dental laboratories. Our product line, including Muffle, Tube, Rotary Furnaces, Vacuum & Atmosphere Furnaces, and CVD/PECVD Systems, is complemented by strong deep customization capabilities to precisely meet your unique experimental needs—ensuring perfect restorations with superior strength, aesthetics, and efficiency. Contact us today to discuss how we can enhance your sintering process and boost your productivity!

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why is using a universal setting for all materials in a dental furnace a mistake? Master Precision Sintering for Perfect Restorations

- Why is accurate temperature control important in dental furnaces? Ensure Perfect Restorations Every Time

- What role does temperature range and accuracy play in dental furnace performance? Ensure Precision for Superior Dental Restorations

- What is the working principle of a dental furnace? Mastering Precision Sintering & Firing for Crowns

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision