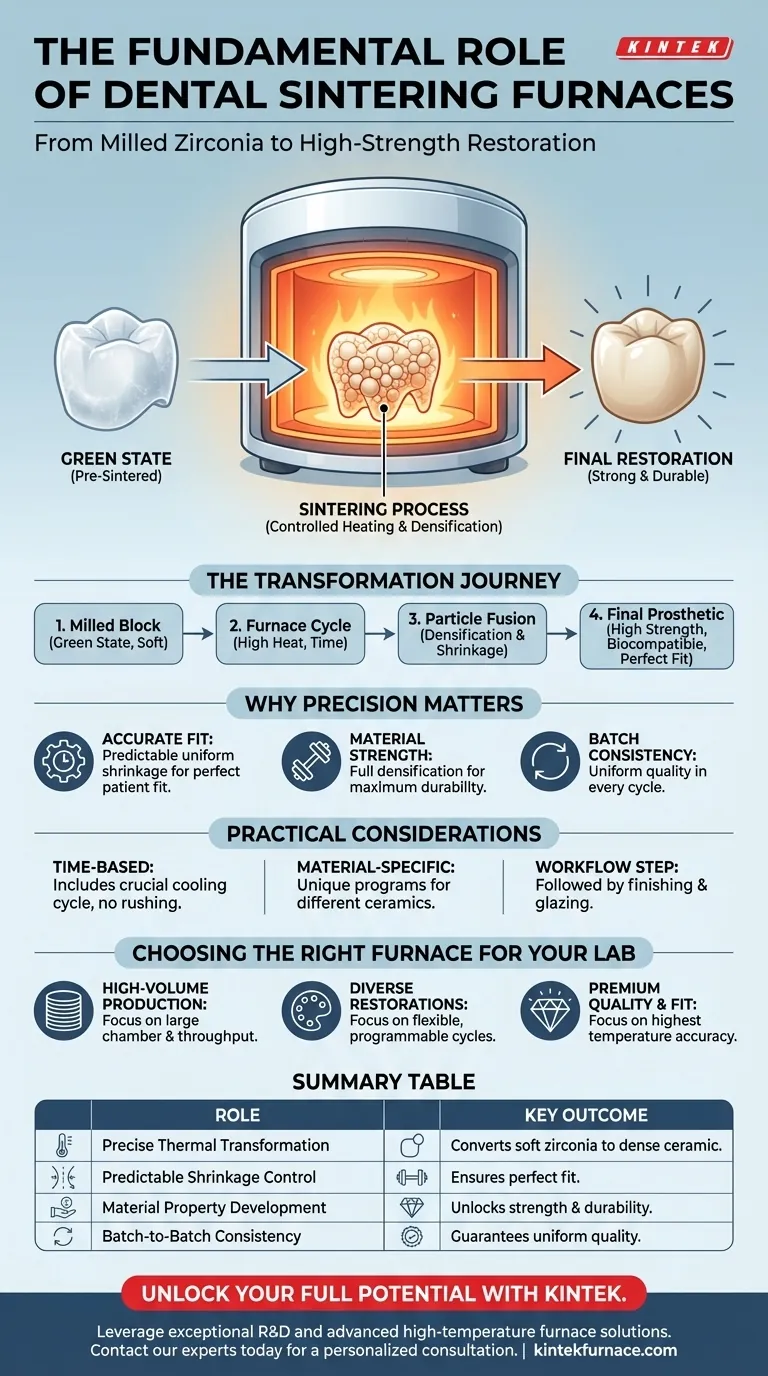

At its core, a dental sintering furnace is a high-precision oven that transforms a fragile, milled ceramic shape into a final, incredibly durable dental restoration. It accomplishes this through a controlled heating process called sintering, which fuses ceramic particles together to achieve the material's final density, strength, and stability.

The fundamental role of a sintering furnace is not just to heat a material, but to precisely manage a critical material transformation. It's the essential step that converts a chalky, oversized pre-form into a strong, biocompatible, and perfectly fitting final crown, bridge, or framework.

From Milled Block to Final Prosthetic

The journey of a modern ceramic restoration, like one made from zirconia, hinges entirely on the sintering process. The furnace is where the material's potential is fully realized.

The Starting Point: A Pre-Sintered "Green" State

A restoration begins as a digital design that is milled from a block of zirconia. At this stage, the material is in a pre-sintered or "green" state, which is soft enough to be milled easily but lacks any significant strength.

The Sintering Transformation

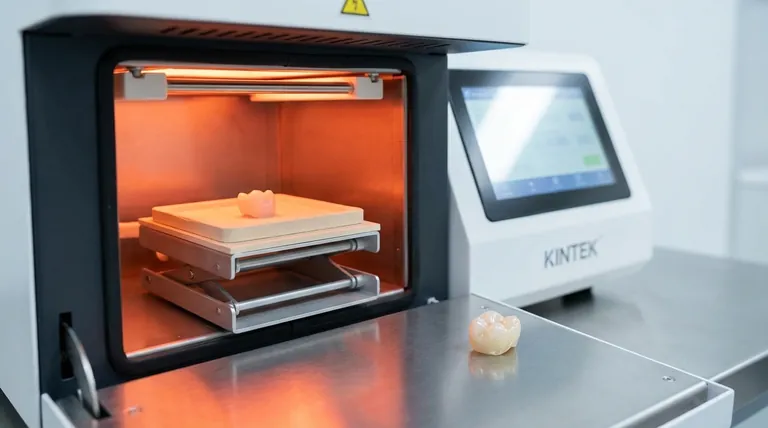

The milled restoration is placed into the furnace, which executes a highly specific heating program. This cycle involves precise temperature ramps and holds, often reaching very high temperatures.

This controlled heat causes the individual ceramic particles to bond and fuse together. This process drives out porosity, causing the material to shrink and densify significantly.

The Final Result: Strength and Stability

Through this densification and crystallization, the restoration gains its exceptional final strength, biocompatibility, and durability. The soft, chalk-like pre-form is transformed into a solid ceramic capable of withstanding the immense forces of chewing.

Why Precision is the Defining Factor

The quality of a sintering furnace is measured by its precision. Inaccurate or inconsistent heating can ruin a restoration, wasting both time and materials.

Ensuring Accurate Fit

The sintering process involves predictable shrinkage. Dental design software accounts for this shrinkage, but it relies on the furnace to perform the cycle perfectly. Precise temperature control ensures this shrinkage is uniform and correct, resulting in a restoration that fits the patient perfectly.

Guaranteeing Material Strength

The final properties of the ceramic are directly tied to the sintering cycle. If the temperature is too low or the hold time is too short, the material will not fully densify, resulting in a weak and unreliable restoration.

Achieving Batch-to-Batch Consistency

For a dental lab, consistency is key. A high-quality furnace with precise atmosphere and temperature control ensures that every restoration in a batch, and every batch over time, meets the same high standard of quality.

Understanding the Practical Considerations

While essential, the sintering process has operational factors that must be managed for a successful workflow.

Sintering is a Time-Based Process

The heating, holding, and especially the cooling cycles take a significant amount of time. This is not an instant process and must be factored into the lab's production schedule. Rushing the cooling can cause thermal shock and crack the restoration.

Different Materials Require Different Programs

Not all ceramics are the same. Different types of zirconia and other high-strength ceramics require unique, manufacturer-specified sintering programs. A versatile furnace must be capable of accurately running these different temperature profiles.

It's One Step in a Larger Workflow

Sintering is a critical middle step. After the cycle is complete and the restoration has fully cooled, it must still undergo final finishing, staining, glazing, and polishing to achieve the desired aesthetic result.

Making the Right Choice for Your Lab

The importance of the furnace means the choice directly impacts your lab's output, quality, and capabilities.

- If your primary focus is high-volume production: You need a furnace with a large chamber and proven reliability to ensure consistent throughput and minimal downtime.

- If your primary focus is offering diverse restorations: You need a furnace with flexible, user-programmable cycles to handle the specific requirements of various zirconia and ceramic materials.

- If your primary focus is premium quality and fit: You need a furnace with the most accurate temperature control and heat distribution to guarantee predictable shrinkage and maximum material strength.

Ultimately, the sintering furnace is the final gatekeeper of quality, responsible for unlocking the full clinical potential of modern dental ceramics.

Summary Table:

| Sintering Furnace Role | Key Outcome |

|---|---|

| Precise Thermal Transformation | Converts soft, milled zirconia into a dense, high-strength ceramic. |

| Predictable Shrinkage Control | Ensures the final restoration fits the patient's preparation perfectly. |

| Material Property Development | Unlocks the ceramic's full strength, biocompatibility, and durability. |

| Batch-to-Batch Consistency | Guarantees uniform quality for every crown, bridge, or framework produced. |

Ready to unlock the full potential of your dental ceramics?

Your lab's reputation depends on the precision and reliability of your sintering process. At KINTEK, we leverage exceptional R&D and in-house manufacturing to provide dental laboratories with advanced high-temperature furnace solutions. Our product line, including Atmosphere Furnaces, is complemented by strong deep customization capabilities to precisely meet your unique production requirements—whether you focus on high-volume output, diverse material compatibility, or premium aesthetic results.

Let's discuss how a KINTEK furnace can become the reliable core of your production workflow. Contact our experts today for a personalized consultation.

Visual Guide

Related Products

- Chairside Dental Porcelain Zirconia Sintering Furnace with Transformer for Ceramic Restorations

- Dental Porcelain Zirconia Sintering Ceramic Vacuum Press Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- 1700℃ Controlled Inert Nitrogen Atmosphere Furnace

People Also Ask

- What is the importance of dental furnaces in dentistry? Ensure Strong, Precise Dental Restorations

- Why is temperature range important when selecting a dental furnace? Unlock Material Compatibility and Precision

- What are the primary functions of ceramic dental furnaces? Achieve Precision and Durability in Dental Restorations

- How often should dental furnaces be calibrated? Ensure Precision for Perfect Restorations

- What aspects of a dental restoration are directly impacted by the choice of a dental sintering furnace? Ensure Fit, Strength & Longevity