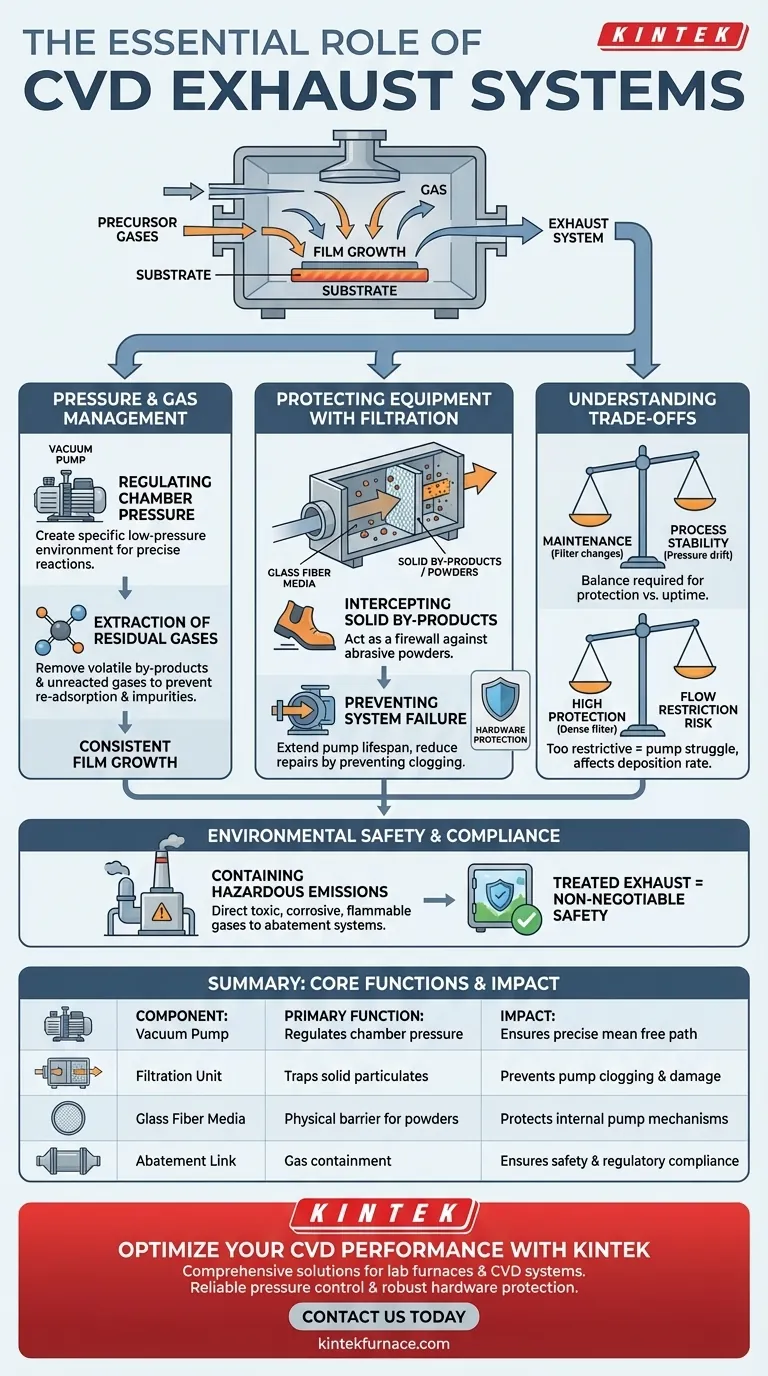

The exhaust system in Chemical Vapor Deposition (CVD) serves as the primary mechanism for maintaining reaction integrity and protecting hardware. Its fundamental purpose is to establish a specific low-pressure environment within the chamber while actively removing volatile by-products and unreacted gases. By integrating high-performance vacuum pumps with specialized filtration units, the system prevents equipment contamination and ensures the safety of the manufacturing environment.

Core Insight: The exhaust system is not merely a waste removal line; it is a critical regulation loop. While vacuum pumps provide the necessary pressure gradient for the chemical reaction, filtration units act as a firewall, intercepting abrasive powders to prevent catastrophic pump failure and ensure consistent film growth.

The Critical Role of Pressure and Gas Management

Regulating Chamber Pressure

The CVD process typically operates under vacuum conditions to facilitate precise chemical reactions. The exhaust system’s vacuum pumps are responsible for evacuating air to create this low-pressure environment.

By strictly controlling the pressure, the system regulates the mean free path of gas molecules. This ensures that precursor gases can travel to the substrate effectively without premature reactions or scattering.

Extraction of Residual Gases

During the deposition process, precursor gases decompose to form the desired solid film. This reaction simultaneously generates volatile by-products and leaves behind unreacted precursor gases.

The exhaust system must continuously extract these residual gases. Efficient removal prevents these by-products from re-adsorbing onto the substrate, which would otherwise introduce impurities and degrade the quality of the coating.

Protecting Equipment with Filtration

Intercepting Solid By-Products

CVD reactions often generate solid particulates or powders in addition to gaseous by-products. If left unchecked, these solids can migrate out of the chamber and into the downstream vacuum infrastructure.

Filtration units are strategically placed between the reaction chamber and the vacuum pumps to capture these particulates. This separation is vital for maintaining the mechanical health of the pumping system.

The Role of Glass Fiber Media

Many CVD systems utilize specific filtration media, such as glass fiber, designed to trap fine powders. These filters act as a physical barrier, ensuring that only gaseous matter reaches the sensitive internal mechanisms of the vacuum pumps.

Preventing System Failure

Without adequate filtration, solid by-products would rapidly accumulate in vacuum lines and pump housings. This leads to clogging, reduced conductance (flow ability), and severe physical damage to the vacuum pumps.

By intercepting these contaminants, the filtration unit extends the operational lifespan of the vacuum pumps and reduces the frequency of costly repairs.

Understanding the Trade-offs

Maintenance vs. Process Stability

The inclusion of filtration units introduces a necessary maintenance requirement. As filters capture powder, they eventually become saturated, which can restrict gas flow and alter chamber pressure.

Operators must balance the need for protection with the need for process stability. Failing to change filters leads to pressure drifts that ruin film uniformity, while frequent changes require system downtime.

Flow Restriction Risks

While a dense filter offers the best protection for the pump, it also imposes the highest restriction on gas flow.

If the filtration is too restrictive, the vacuum pumps may struggle to maintain the required low pressure, potentially affecting the deposition rate and the chemical composition of the film.

Environmental Safety and Compliance

Containing Hazardous Emissions

The gases and by-products exhausted from a CVD chamber are often toxic, corrosive, or flammable. The exhaust system does not simply vent these into the atmosphere.

The system ensures that these gases are contained and directed toward abatement systems. Treated exhaust is a non-negotiable requirement for ensuring the environmental safety of the overall manufacturing facility and protecting personnel.

Making the Right Choice for Your Goal

The configuration of your exhaust system dictates the reliability and safety of your CVD process.

- If your primary focus is Equipment Longevity: Prioritize high-capacity filtration units with glass fiber media to aggressively trap powders and maximize the lifespan of your vacuum pumps.

- If your primary focus is Film Purity: Ensure your vacuum pumps are sized to maintain optimal flow rates even as filters begin to load, preventing backstreaming or pressure fluctuations.

An effective exhaust system transforms the CVD process from a volatile chemical reaction into a controlled, repeatable manufacturing capability.

Summary Table:

| Component | Primary Function | Impact on CVD Process |

|---|---|---|

| Vacuum Pump | Regulates chamber pressure | Ensures precise mean free path for gas molecules |

| Filtration Unit | Traps solid particulates | Prevents pump clogging and mechanical damage |

| Glass Fiber Media | Physical barrier for powders | Protects internal pump mechanisms from abrasion |

| Abatement Link | Gas containment | Ensures environmental safety and regulatory compliance |

Optimize Your CVD Performance with KINTEK

Don't let inefficient exhaust management compromise your film purity or damage your vacuum systems. Backed by expert R&D and manufacturing, KINTEK offers a comprehensive range of lab high-temperature furnaces, including Muffle, Tube, Rotary, Vacuum, and CVD systems.

Our equipment is fully customizable to meet your unique research or production needs, ensuring reliable pressure control and robust hardware protection. Contact us today to discover how our tailored solutions can enhance your laboratory’s efficiency and process stability.

Visual Guide

References

- Junyu Zhu, Xuxiang Zhang. Oxidation Resistance of Ir/HfO2 Composite Coating Prepared by Chemical Vapor Deposition: Microstructure and Elemental Migration. DOI: 10.3390/coatings14060695

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

- Split Chamber CVD Tube Furnace with Vacuum Station CVD Machine

- 1700℃ High Temperature Laboratory Tube Furnace with Quartz or Alumina Tube

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- MPCVD Machine System Reactor Bell-jar Resonator for Lab and Diamond Growth

People Also Ask

- How is CVD applied in solar cell production? Boost Efficiency with Advanced Thin-Film Deposition

- What materials can be deposited using CVD? Unlock Versatile Thin Films for Your Applications

- What materials are used in CVD? A Guide to High-Performance Thin Films for Your Lab

- How does the CVD process work? Master High-Quality Thin Film Deposition for Your Lab

- Why is an oxygen analyzer at the R2R exhaust critical? Ensure Explosion-Proof Processing Safety

- What is the application of CVD in cutting tools? Boost Tool Life and Machining Efficiency

- Why must a CVD system use high-precision MFCs? Achieve Atomic Perfection in Your Material Synthesis

- What is chemical vapor phase deposition? Unlock High-Performance Thin Films for Your Lab