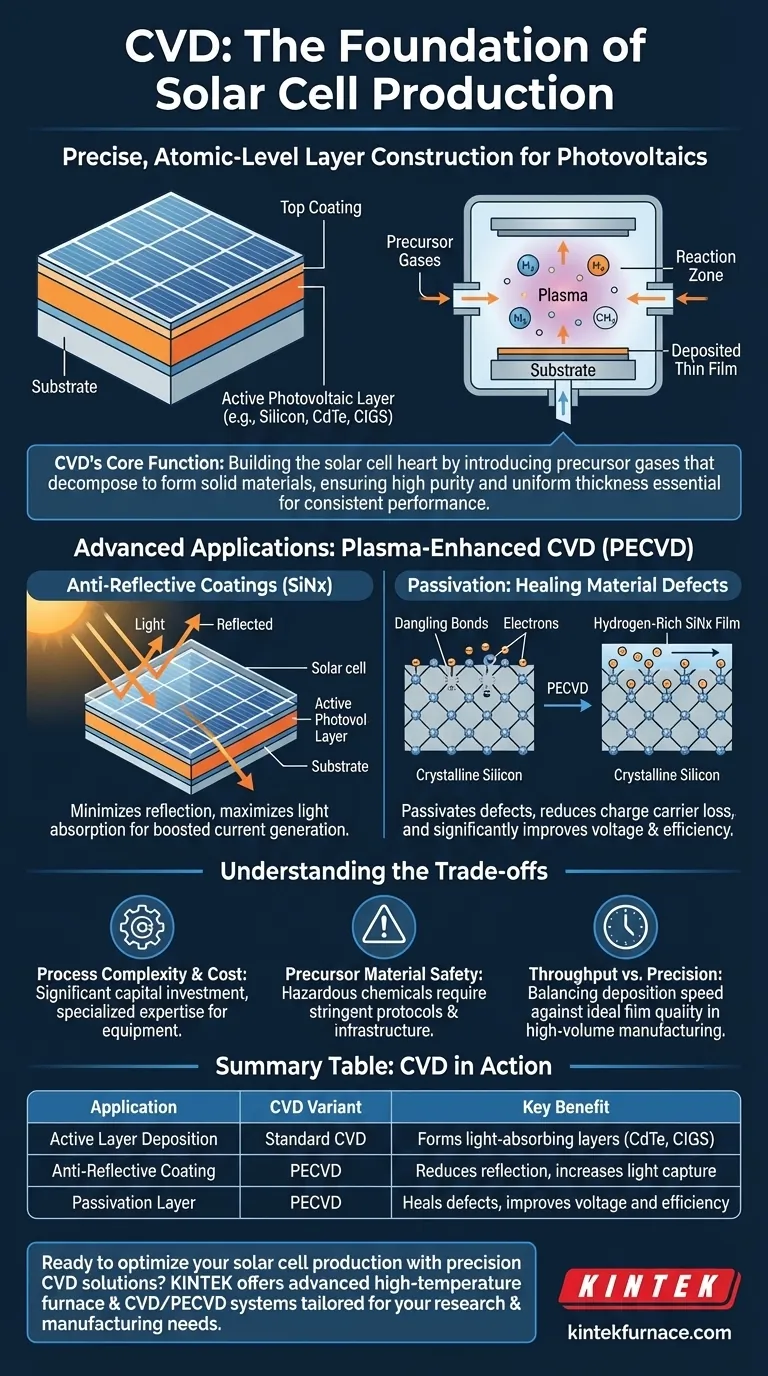

In solar cell manufacturing, Chemical Vapor Deposition (CVD) is the foundational technique used to construct the critical, ultra-thin functional layers of a photovoltaic device. It precisely deposits materials—from the primary light-absorbing layer to performance-enhancing coatings—onto a substrate. This atomic-level control over film thickness and composition is essential for optimizing the cell's efficiency and cost-effectiveness.

CVD and its variants are indispensable for modern solar cells because they allow for the precise construction of thin films. This control directly translates to higher sunlight absorption, improved electron flow, and ultimately, greater energy conversion efficiency and durability.

The Core Function: Building a Solar Cell Layer by Layer

The primary role of CVD in this context is to build the functional heart of the solar cell. It achieves this by introducing precursor gases into a reaction chamber, which then decompose and deposit a solid material onto the solar cell substrate.

Depositing the Active Photovoltaic Layer

For many thin-film solar cells, CVD is the process used to create the very layer that absorbs sunlight and converts it into electricity.

This active layer can be made of various photovoltaic materials, including silicon, cadmium telluride (CdTe), or copper indium gallium selenide (CIGS).

Achieving High Purity and Uniformity

The CVD process allows for exceptionally precise control over the deposition rate. This ensures the resulting film has a highly uniform thickness and purity across the entire substrate.

This uniformity is critical for consistent and predictable performance, as variations in thickness or impurities can severely degrade a solar cell's efficiency.

Advanced Applications: Plasma-Enhanced CVD (PECVD)

A specific and widely used variant, Plasma-Enhanced Chemical Vapor Deposition (PECVD), has become a cornerstone of modern solar cell fabrication, particularly for crystalline silicon cells. It uses a plasma to energize the precursor gases, allowing the deposition process to occur at much lower temperatures.

Applying Anti-Reflective Coatings

Sunlight reflecting off the surface of a solar cell is wasted energy. PECVD is used to deposit an anti-reflective coating, most commonly silicon nitride (SiNx), onto the top of the cell.

This microscopically thin layer is engineered to minimize reflection and maximize the amount of light that enters the active photovoltaic material, directly boosting current generation.

Passivation: Healing Material Defects

Beyond optics, the silicon nitride film serves a second, crucial electronic function: passivation. The hydrogen-rich film effectively "heals" defects in the silicon crystal structure, such as dangling bonds.

By neutralizing these defects, the film reduces the chances that charge carriers (electrons) get trapped and lost. This improves charge carrier mobility and significantly enhances the cell's overall voltage and efficiency.

Understanding the Trade-offs

While powerful, CVD is not without its complexities. Understanding its limitations is key to appreciating its role in manufacturing.

Process Complexity and Cost

CVD equipment, especially PECVD systems, involves sophisticated vacuum chambers, gas delivery systems, and power sources. This represents a significant capital investment and requires specialized expertise to operate and maintain.

Precursor Material Safety

The chemicals used as precursors in CVD can be hazardous, toxic, or flammable. This necessitates stringent safety protocols, handling procedures, and infrastructure, adding to the operational complexity.

Throughput vs. Precision

CVD offers unparalleled precision, but it can be a relatively slow process. In high-volume manufacturing, there is a constant trade-off between the deposition speed (throughput) and the ideal quality of the deposited film.

Making the Right Choice for Your Goal

The specific application of CVD depends directly on the type of solar cell being produced and the desired performance characteristics.

- If your primary focus is producing high-efficiency crystalline silicon cells: PECVD is non-negotiable for depositing the silicon nitride anti-reflective and passivation layers that maximize performance.

- If your primary focus is manufacturing thin-film solar cells: A suitable CVD process is the core technology for depositing the main light-absorbing layer, such as CdTe or CIGS.

- If your primary focus is optimizing cost-per-watt: The choice of CVD variant becomes a critical balance between deposition speed, film quality, and equipment cost to drive down manufacturing expenses.

Ultimately, mastering CVD is mastering the ability to engineer light absorption and electron flow at the atomic scale—the very essence of photovoltaic efficiency.

Summary Table:

| Application | CVD Variant | Key Benefit |

|---|---|---|

| Active Layer Deposition | Standard CVD | Forms light-absorbing layers (e.g., CdTe, CIGS) |

| Anti-Reflective Coating | PECVD | Reduces reflection, increases light capture |

| Passivation Layer | PECVD | Heals defects, improves voltage and efficiency |

Ready to optimize your solar cell production with precision CVD solutions? KINTEK leverages exceptional R&D and in-house manufacturing to provide advanced high-temperature furnace systems, including CVD/PECVD systems, tailored for laboratories focused on photovoltaic development. Our deep customization capabilities ensure we meet your unique experimental needs, enhancing efficiency and durability in solar cell fabrication. Contact us today to discuss how our solutions can elevate your research and manufacturing processes!

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma Enhanced Chemical Vapor Deposition

- Inclined Rotary Plasma Enhanced Chemical Deposition PECVD Tube Furnace Machine

- Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Custom Made Versatile CVD Tube Furnace Chemical Vapor Deposition CVD Equipment Machine

People Also Ask

- Why is a high-precision PECVD system required in ACSM? Enable Low-Temperature Atomic-Scale Manufacturing

- How does a CVD system ensure the quality of carbon layers? Achieving Nanometer Precision with KINTEK

- What is the function of a PECVD system in the passivation of UMG silicon solar cells? Enhance Efficiency with Hydrogen

- What environments does a PECVD system provide for silicon nanowires? Optimize Growth with Precise Thermal Control

- Why Use PECVD for Monolithic Integrated Chip Isolation Layers? Protect Your Thermal Budget with High-Quality SiO2