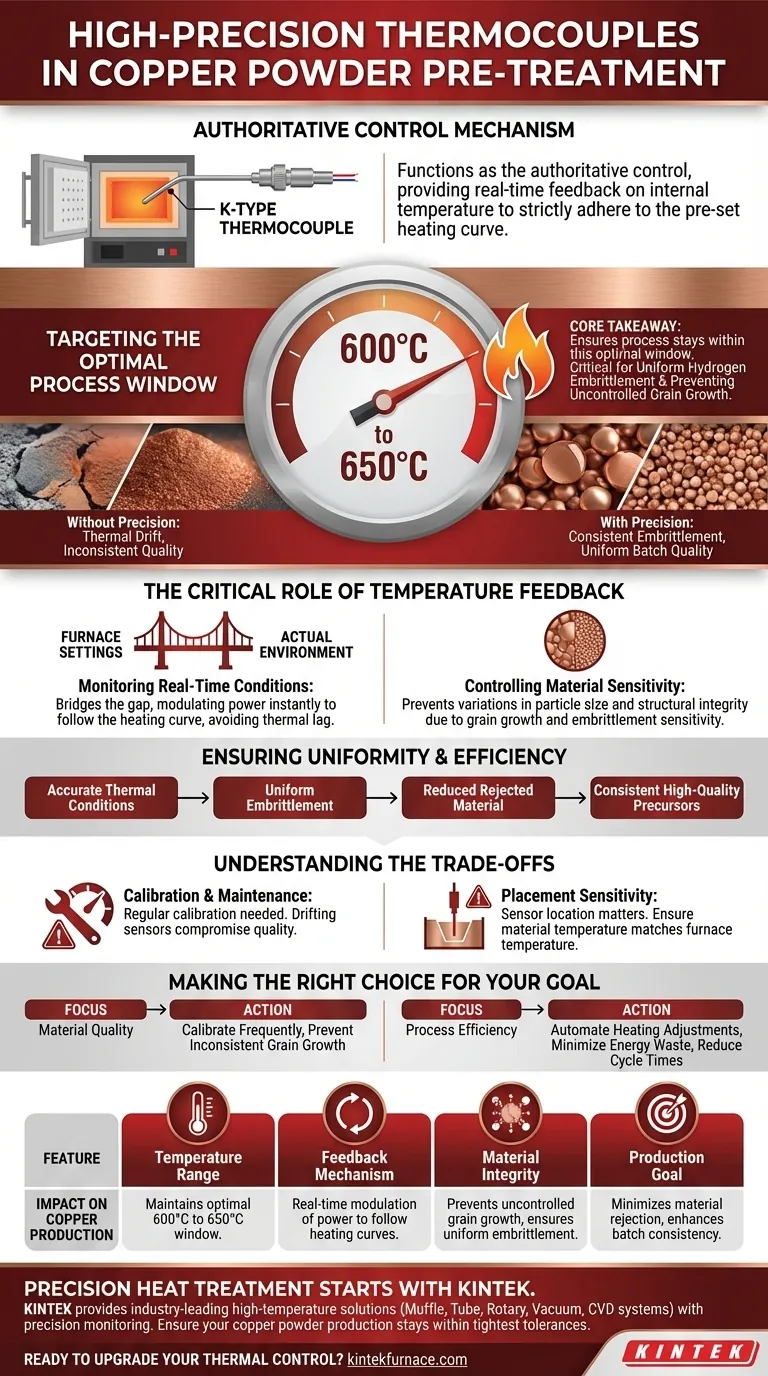

High-precision thermocouples function as the authoritative control mechanism within the furnace during the pre-treatment of copper powder. Specifically, instruments like K-type thermocouples provide real-time feedback on the actual internal temperature, ensuring the annealing process strictly adheres to the pre-set heating curve. Without this continuous monitoring, the precise thermal environment required for chemical and physical transformation cannot be maintained.

Core Takeaway The primary role of these sensors is to guarantee the process stays within the optimal 600°C to 650°C window. This precision is critical because slight deviations in temperature directly impact the uniformity of hydrogen embrittlement and can lead to uncontrolled copper grain growth.

The Critical Role of Temperature Feedback

Monitoring Real-Time Conditions

The fundamental function of the thermocouple is to bridge the gap between the furnace's settings and the actual internal environment.

Heating elements may fluctuate, but high-precision thermocouples provide real-time feedback.

This data allows the system to modulate power instantly, ensuring the annealing process strictly follows the designated heating curve rather than drifting due to thermal lag or load variations.

Controlling Material Sensitivity

Copper powder production is chemically delicate during the pre-treatment stage.

Both copper grain growth and the degree of hydrogen embrittlement are highly sensitive to temperature changes.

If the monitoring is inaccurate, the physical properties of the final powder will vary, leading to inconsistencies in particle size and structural integrity.

Targeting the Optimal Process Window

The 600°C to 650°C Threshold

The primary reference identifies a specific temperature window that dictates success: 600°C to 650°C.

This is the optimal range for hydrogen embrittlement.

High-precision thermocouples are the only reliable way to ensure the material reaches and sustains this specific temperature without overshooting, which could alter the grain structure detrimental to the powder's quality.

Ensuring Uniformity and Efficiency

Beyond mere temperature tracking, these sensors are vital for production efficiency.

By maintaining accurate thermal conditions, manufacturers ensure uniform embrittlement across the entire batch.

This reduces the rate of rejected material and ensures the pre-treatment phase yields consistent, high-quality copper precursors ready for crushing or further processing.

Understanding the Trade-offs

Calibration and Maintenance

While high-precision thermocouples like K-types are robust, their accuracy is not absolute forever.

They require regular calibration to ensure the feedback loop remains valid.

A drifting sensor can report that the furnace is in the optimal 600–650°C range when it is actually outside of it, quietly compromising the batch quality.

Placement Sensitivity

The feedback provided is only as good as the sensor's location.

A thermocouple measures temperature at a specific point, which may differ from the center of the copper load.

Operators must understand that "furnace temperature" and "material temperature" can diverge, necessitating careful sensor placement or soak times to ensure the copper actually reaches the target state.

Making the Right Choice for Your Goal

To maximize the effectiveness of high-precision thermocouples in your production line:

- If your primary focus is Material Quality: Calibrate sensors frequently to ensure the furnace strictly maintains the 600°C to 650°C window, preventing inconsistent grain growth.

- If your primary focus is Process Efficiency: Utilize the real-time feedback data to automate heating adjustments, minimizing energy waste and reducing cycle times.

Precise temperature monitoring is the difference between processing copper and truly engineering its microstructure.

Summary Table:

| Feature | Impact on Copper Powder Production |

|---|---|

| Temperature Range | Maintains optimal 600°C to 650°C window |

| Feedback Mechanism | Real-time modulation of power to follow heating curves |

| Material Integrity | Prevents uncontrolled grain growth and ensures uniform embrittlement |

| Production Goal | Minimizes material rejection and enhances batch consistency |

Precision Heat Treatment Starts with KINTEK

Don't let thermal drift compromise your material integrity. KINTEK provides industry-leading high-temperature solutions, including Muffle, Tube, Rotary, Vacuum, and CVD systems, all designed with precision monitoring to meet your specific lab or industrial requirements. Backed by expert R&D and manufacturing, our systems ensure your copper powder production or advanced material research stays within the tightest tolerances.

Ready to upgrade your thermal control? Contact our experts today to discuss your custom furnace needs.

Visual Guide

References

- Falah Mustafa Al-Saraireh. The Effect of Annealing Conditions on Copper's Brittleness and Powder Production Efficiency. DOI: 10.21062/mft.2025.035

This article is also based on technical information from Kintek Furnace Knowledge Base .

Related Products

- 1400℃ High Temperature Laboratory Tube Furnace with Quartz and Alumina Tube

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- Laboratory Muffle Oven Furnace with Bottom Lifting

People Also Ask

- Why are silicon carbide heating elements preferred in kilns and pottery? For High-Temp, Uniform Heat & Durability

- What are the advantages of using T-type fine-wire thermocouples for monitoring coal pyrolysis pretreatment?

- What operating conditions should be avoided with MoSi2 heating elements? Prevent Premature Failure and Extend Lifespan

- What are the characteristics of molybdenum disilicide heating elements? Unlock High-Temp Performance

- What should be considered when selecting graphite heating elements for a specific application? Optimize Your High-Temperature Process

- What is watt-density and why is it important in heating element design? Ensure Efficiency and Longevity

- What role do composite heating elements play in specialized industries? Achieve Durable, Precise Heating for Harsh Environments

- How do ceramic heating elements with a positive temperature coefficient behave? Discover Self-Regulating Safety & Efficiency